Burkert Type 8686 User Manual

Page 35

35

Controlanddisplay

Bot

gn ye

Bot

To

p

To

p

Typ 8685

Typ 8686

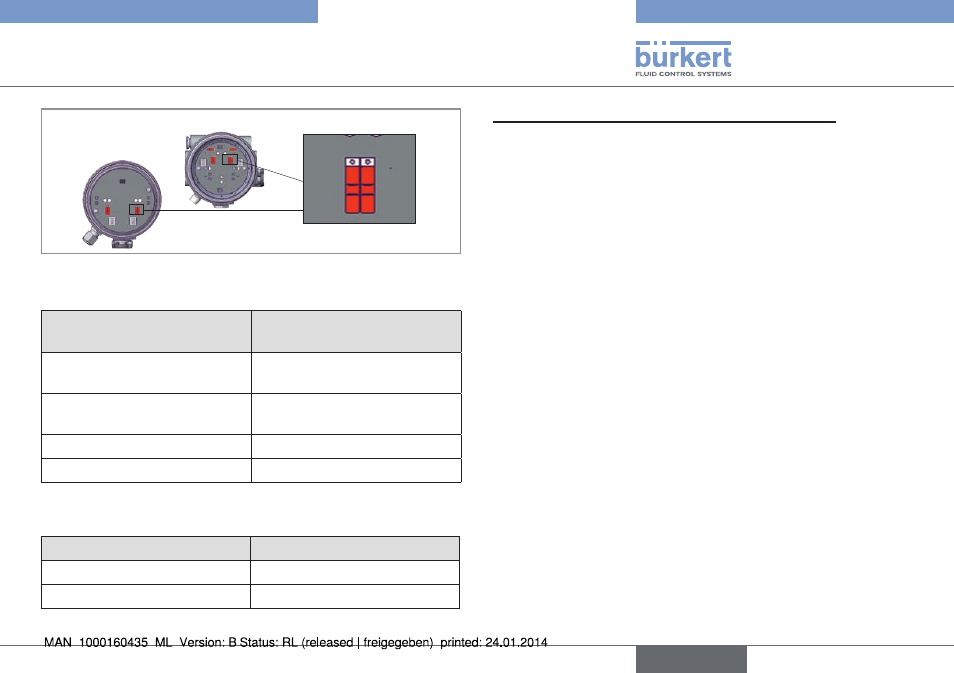

Fig. 29: Color assignment of end positions via slide switch

Refer to the PCB labeling in the table below

switch position for one

actuator side

actuator status led

Both switches up

End position Top yellow /

End position Bot green

Both switches down

End position Top green /

End position Bot yellow

Switch up/down

- Invalid state -

Switch down/up

- Invalid state -

Tab. 13: Color assignment of end positions

The following function is set in the factory:

color

actuator status

Green LED lit

Lower end position

Yellow LED lit

Upper end position

Tab. 14: Assignment of status of actuator LEDs (end position)

step 3: reference movement for spindle adjustment

To make the fine adjustment of the spindle for actuator size, it is essential

to move both spindles from the lower to the top end position.

procedure for type 8685:

Actuator with design control function A (CFA, NC):

→

Under maximum control pressure, move the spindles up by acti-

vating the actuator chambers.

→

After the end position is reached (preselected LED is lit), turn off

the control pressure. The spindle moves to the lower end position.

LED for end position Bot is lit with the selected color.

Actuator with design control function B (CFB, NO):

→

Under maximum control pressure, move the spindles down by

activating the actuator chambers.

→

After the end position is reached (preselected LED is lit), turn

off the control pressure. The spindle moves to the upper end

position. The corresponding LED for the end position is lit with

the selected color.

English

Type 8685 / 8686