Franklin Fueling Systems TS-LS300 AutoLearn Pressure-Based Electronic Line Leak Detector System Users Guide User Manual

Page 6

PREFACE

Page

P-3

P

LS300 User’s Guide

Each product line must be precision tested and verified free of leaks before any component of the

LS300 system is installed. After verification, the LS300 Auto-Learn

®

system is installed, wired, and

calibrated. The supplied leak-generating device/calibration kit* is attached to a needle valve, and the

appropriate line channel selector switch is placed in the learn position at the console. Each line is

calibrated separately, one at a time, to “learn” the parameters and characteristics of a line with a

known induced leak-rate.

At each STP housing, the needle valve kits* are assembled and installed in the pressure test ports,

and the LSU300 pressure-transducers are installed in 2 inch NPT line leak detector ports (LSU300

cable length must not exceed 500 feet).

After a line is calibrated the leak-generator device is moved to the next product line for Auto-Learn

calibration. The entire process is repeated until all lines are separately calibrated and the console is

left in the Run – Detect mode.

The front panel has a power on light and 4 status-lights per line. The status lights show currently

running line leak tests, faults, and alarms. Fault-alarms will cause indicator lights to blink or flash.

Certain alarms will also activate the internal alarm horn. Manual line leak tests may be started and

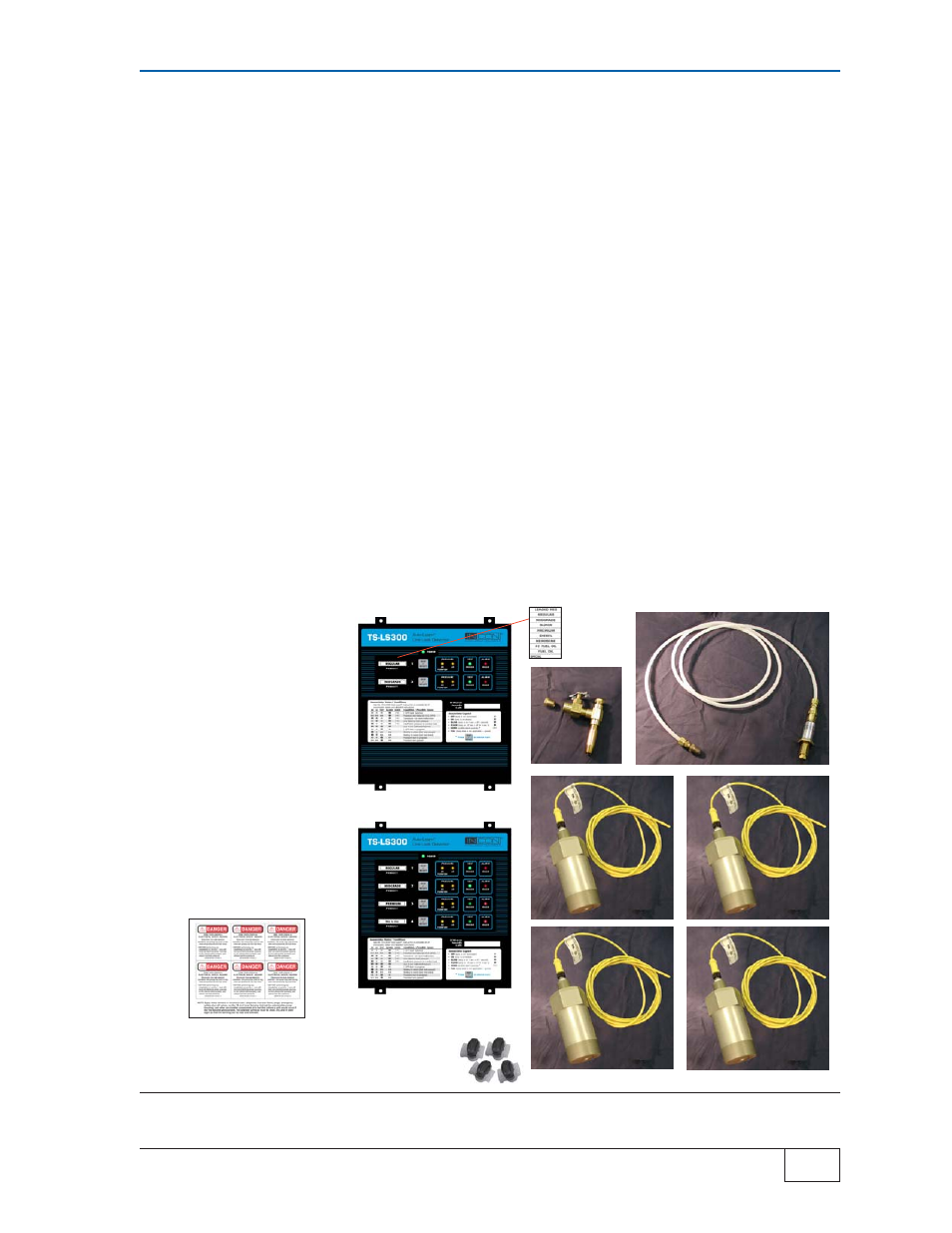

Figure P-1

LS300 LLD System Components

2 CHNL LS300

* The needle valve kit and the leak generating device/calibration kit have not been

evaluated by Underwriters Laboratories.

LEAK GENERATING

DEVICE

NEEDLE

VALVE

LSU300

TRANSDUCER

# 3 with

3 / 4 Chnl

# 4 with

4 Chnl

PRODUCT

ID

STICK-ON

DANGER

3 OR 4 CHNL

NO-STRIP

SPLICE

2 CHNL