Detect mode (operation) troubleshooting – Franklin Fueling Systems TS-LS300 AutoLearn Pressure-Based Electronic Line Leak Detector System Users Guide User Manual

Page 43

TROUBLESHOOTING

Page

6-5

6

LS300 User’s Guide

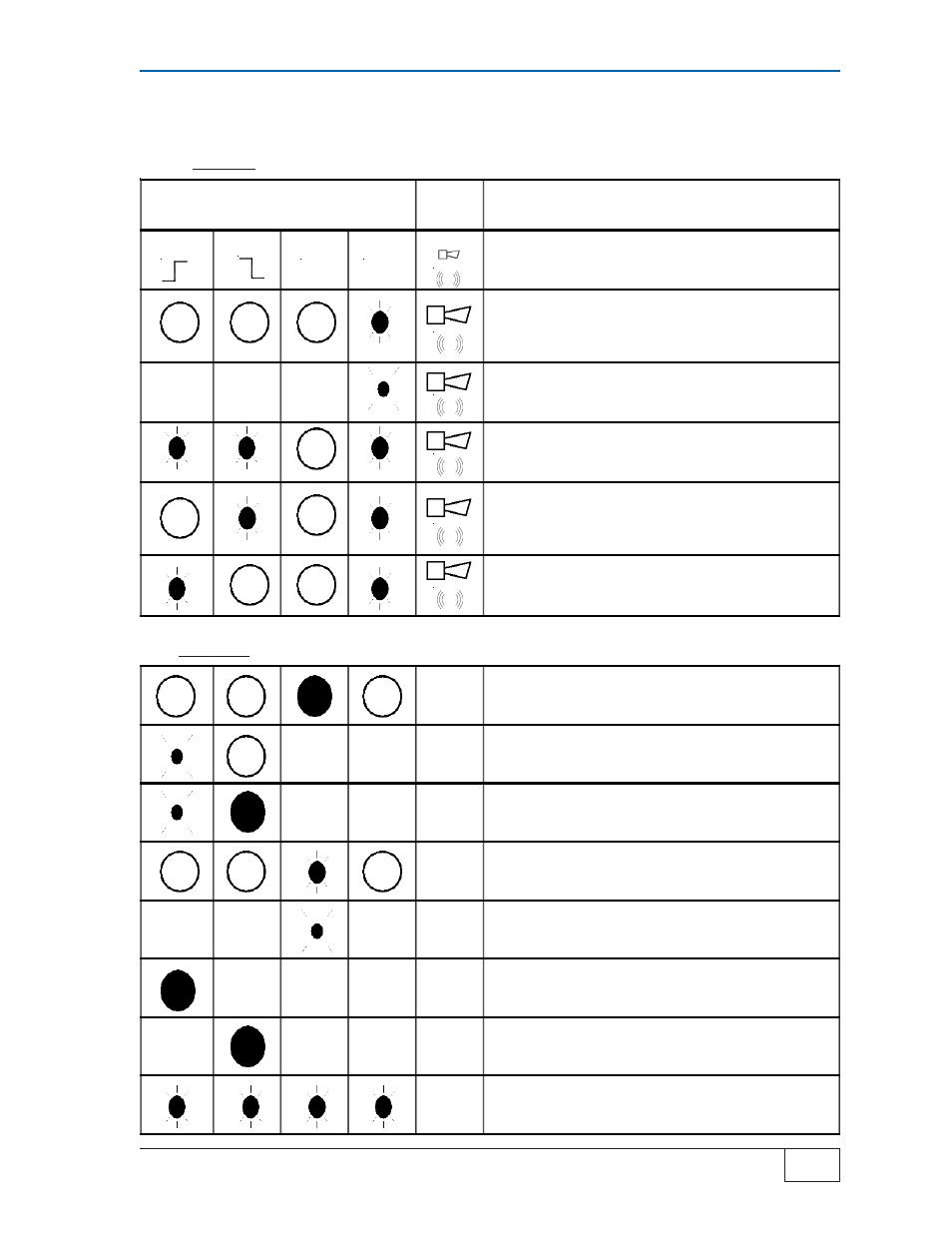

Detect Mode (Operation) Troubleshooting

Lamp Indicators

Audible

Alarm

Conditions and Possible Causes

HI

LOW

TEST

ALARM

HORN

Gross (3 gph) Leak Alarm

- Leak in the system

- Leak in the check valve

- Leak in the manual pressure relief

NA

NA

NA

Monthy or Annual Precision Test Failed

- Monthly (0.2 gph) test failed - one flash

- Annual (0.1 gph) test failed - two flashes

Transducer is not seen

- Mis-wired transducer or Mis-wired Auto-Learn console

- Transducer failure

Pipeline failed to hold pressure

- Leak in the system

- Manual Pressure Relief open

- Check valve removed or stuck open

Insufficient pressure to conduct test

- Leak in the system

- Power to the submersible is OFF

OFF

B

Gross (3 gph) test in progress

- Pressure is within limits

NA

NA

Waiting to retest

- Last test passed

NA

NA

Waiting to retest

- Last test failed

Monthly or Annual Precision test in

progress

- Pressure is within limits

NA

NA

NA

Monthly or Annual Precision test passed

- Monthly (0.2 gph) test passed - one flash

- Annual (0.1 gph) test passed - two flashes

NA

NA

NA

Pump is ON

NA

NA

NA

Pipeline pressure is below 7.5 psi

Calibration is incomplete

- Unit will not detect leaks

ON

B

B

B

B

B

B

B

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

F

F

F

F

B

B

B

B

B

ON

ON

ON

OFF

OFF

T

A

H

Horn ON

Horn OFF

H

H

H

H

H

or

or

or

or

or

or