Learn mode (calibration) troubleshooting – Franklin Fueling Systems TS-LS300 AutoLearn Pressure-Based Electronic Line Leak Detector System Users Guide User Manual

Page 42

6

Page

6-4

TROUBLESHOOTING

LS300 User’s Guide

H

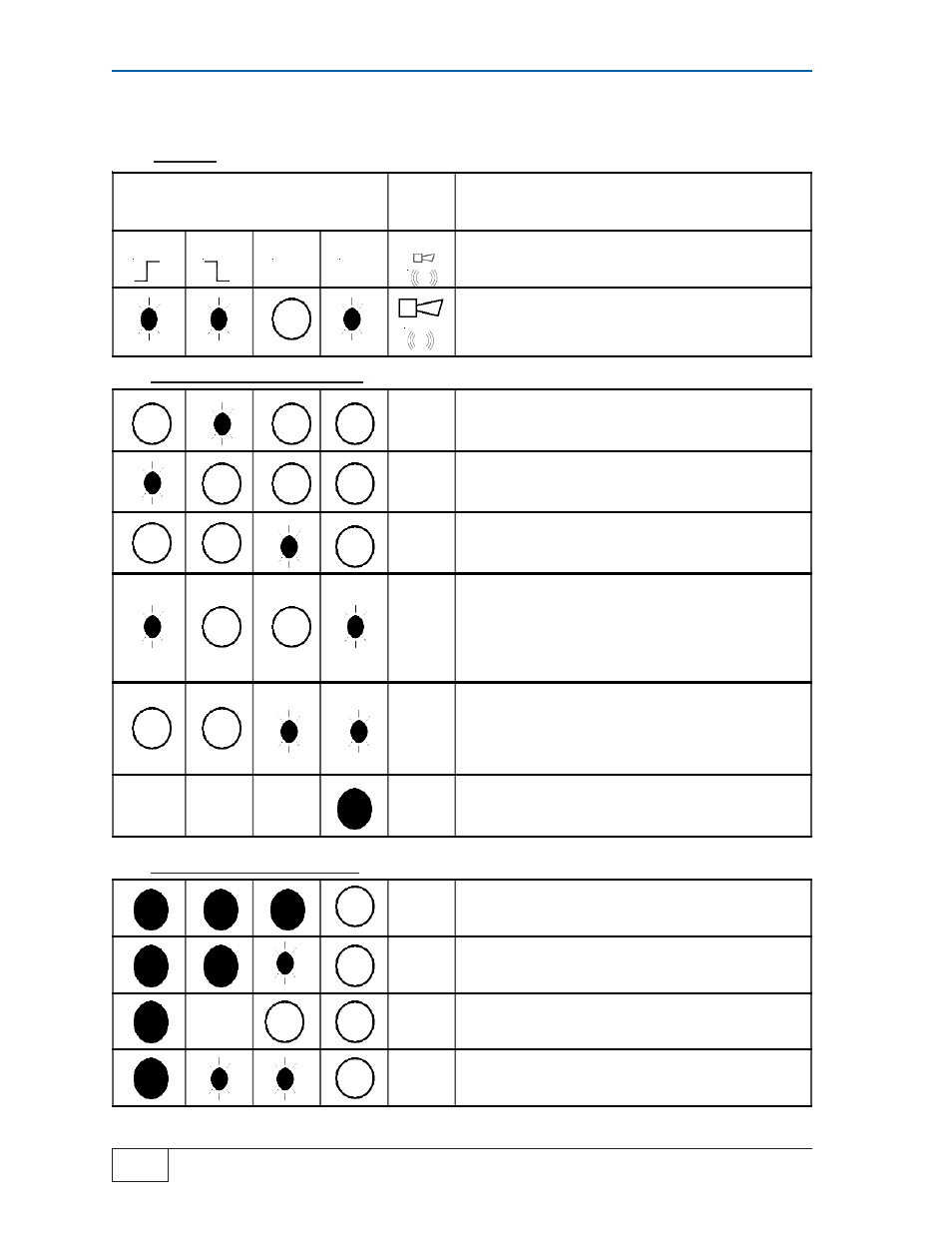

Learn Mode (Calibration) Troubleshooting

Horn ON

Lamp Indicators

Audible

Alarm

Conditions and Possible Causes

HI

LOW

TEST

ALARM

HORN

Transducer not seen

Mis-wired transducer or Mis-wired Auto-Learn

®

console

Transducer failure

OFF

B

B

B

Learning Transducer Zero PSI

- First step in Auto-Learn process

Learning Pump ON Pressure

- Second step in Auto-Learn process

Learning Test Parameters

- Last step in Auto-Learn process

Insufficient Pressure

Console detected pressure less than 17.5 psi

- Broken pipe or open valve

- Line pressure was not bled to zero before calibration

- Power to STP is OFF

- STP is not operating

No Pressure Loss Detected

Pressure decay was not detected

- Leak generator was not installed

- Needle valve on leak generator closed

- Leak generator clogged

NA

NA

NA

Memory Error

- Memory failed to write

ON

B

B

B

B

B

B

B

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Auto-Learn C omplete

- Piping Modulus in range (will perform Gross, monthly

and annual tests)

Auto-Learn C omplete

- Piping Modulus is out of range for annual (0.1 gph)

test

N A

Auto-Learn C omplete

- Insufficient pressure for annual (0.1 gph) test

Auto-Learn C omplete

- Piping Modulus is out of range for the monthly (0.2

gph) and annual (0.1 gph) tests

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

B

B

B

T

A

Horn OFF -- Learning Process

Horn OFF -- Learning Results

H

or

or