Installation – Franklin Fueling Systems TS-550/TS-5000 consoles Secondary Containment Monitoring User Manual

Page 7

4

Installation

Before starting installation, conduct a site survey to identify potential containment groups. Based on that survey, plan out

which STP sump the equipment will be installed in and how containment areas will be grouped together.

Warning

Lockout and tag circuit breakers, and disconnect console power wiring before installing or servicing

any system wiring.

Warning

DO NOT make solenoid and/or sensor wiring connections with live power connected to the console

or any module.

Warning

TS-SCCM contains aluminum, care must be taken to avoid ignition due to impact.

Caution

Do not run intrinsically safe (IS) wiring and non-intrinsically safe (non-IS) wiring in the same

conduit.

Note: TS-SCCM must be installed in accordance with the national electrical code, ANSI/NFPA 70, CEC or other

applicable national or local codes.

Note: Maximum torque on supplied hose clamps is 20 inch-lbs.

1. Pull all wiring through the conduits that will be used for the TS-SCCM vacuum sensor and solenoid valve. The

intrinsically safe (IS) sensor wiring must be run in an IS conduit. The non-IS solenoid wiring must be run in an

approved explosion proof rigid metal conduit.

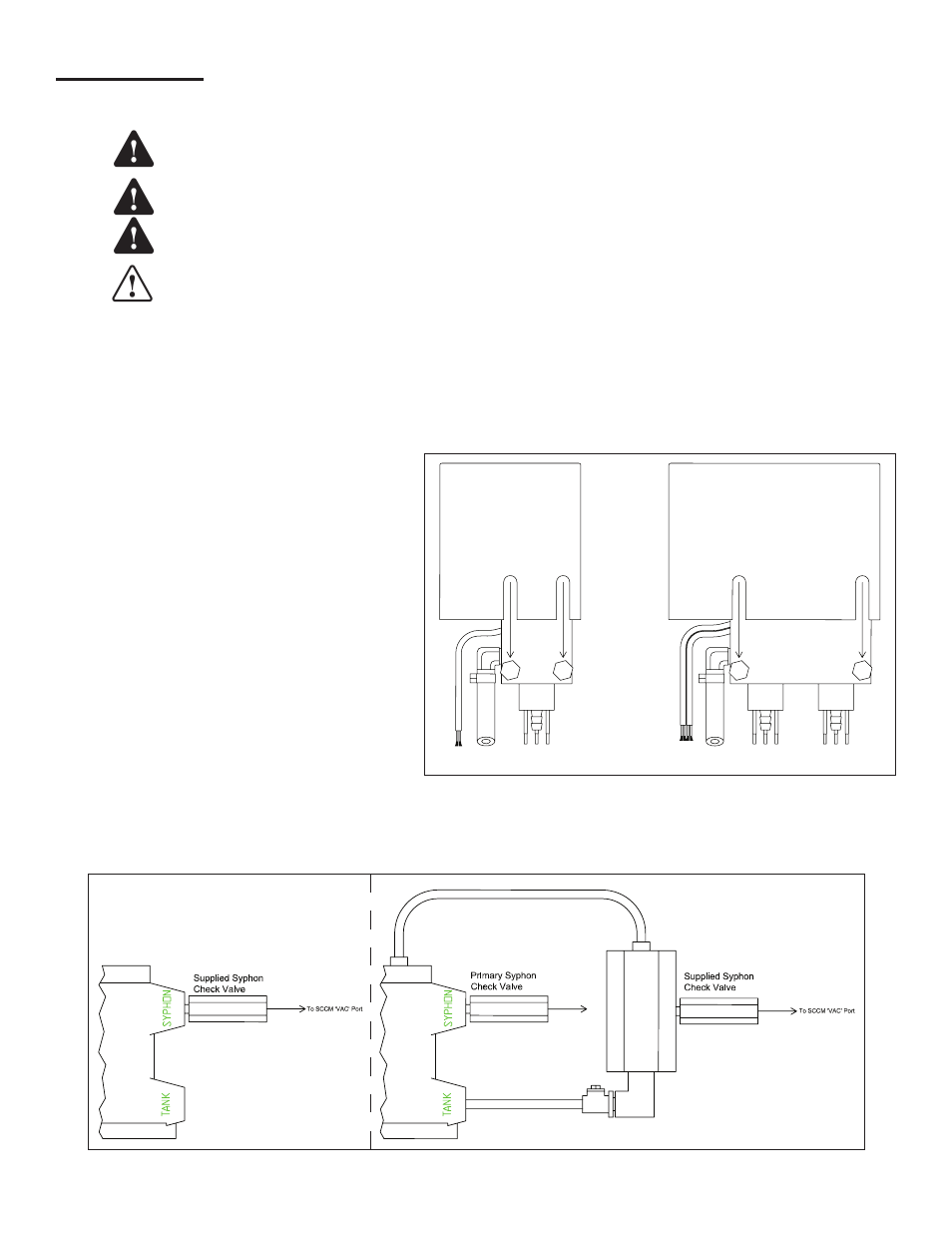

2. Mount the TS-SCCM inside of the turbine

containment area, supported by rigid,

explosion proof conduit. Then orientate the

units to allow enough clearance to make the

vacuum line connections without stretching,

kinking, or creating sharp bends in vacuum

hoses. The SCCM cover is installed with the

label upwards. See Figure 3.

3. Connect the solenoid wiring to the field wiring

using wire nuts to secure the connections.

Replace the explosion proof junction box cover.

4. Connect the vacuum sensor wiring to the IS

field wiring using epoxy wire seals to secure

the connections. Replace the IS junction box

cover.

5. Install the supplied Siphon Check Valve with

the inscribed Flow Arrow pointing to the STP.

Apply a non-hardening, thread sealing

TS-SCCM/1

TS-SCCM/2

Figure 3 – Cover Installation (rear view)

compound to the threads, then thread the valve body into the submersible turbine’s siphon port. If necessary, use a

FFS Secondary Syphon Assembly to connect the SCCM to the syphon port of the STP.

Single Syphon (typical)

Secondary Syphon

Assembly

STP

STP

Secondary Syphon Kit

Figure 4 – Secondary Syphon Assembly Installation