Learn messages – Franklin Fueling Systems TS-550/TS-5000 consoles Secondary Containment Monitoring User Manual

Page 21

18

6. When the message Open Leak Toggle Valve appears, switch the toggle valve to the UP (open) position. SCM will learn

the vacuum decay curve and display Learning Decay Curve on-screen. The vacuum level will begin to fall.

7. When finished, the message Learn Completed – No Errors is displayed on-screen and the Not Learned indicator will

become inactive.

Note: If any errors are encountered at any time during the Learn Process, the screen will display the appropriate error

message and the Not Learned indicator will be active. Refer to the Alarms chapter of this guide for information on

troubleshooting any errors that are displayed.

8. Once the containment has been successfully learned, enable the containment on the Containment Control screen with

the leak generator open. The console will automatically begin a test on the containment. This test should fail, forcing

the containment into alarm status.

9. Close the leak generator. To clear the alarm, navigate to the Containment Control screen and choose

Reset Alarm. If

the Auto-enable on Reset option is turned on in the SCM section of programming, the containment will be automatically

enabled after resetting the alarm condition and will automatically begin a test on the containment. This test should

pass, allowing SCM to continue to monitor the containment. If this test fails, isolate why the test failed, make necessary

repairs, and then retry the test.

10. Remove the leak generator and replace the leak generator plug. Apply TFP tape sealant to the threads of the plug,

then tighten the plug.

If alarms or errors occur, refer to the Alarms chapter of this guide. When the condition is

corrected, restart the Learn Process.

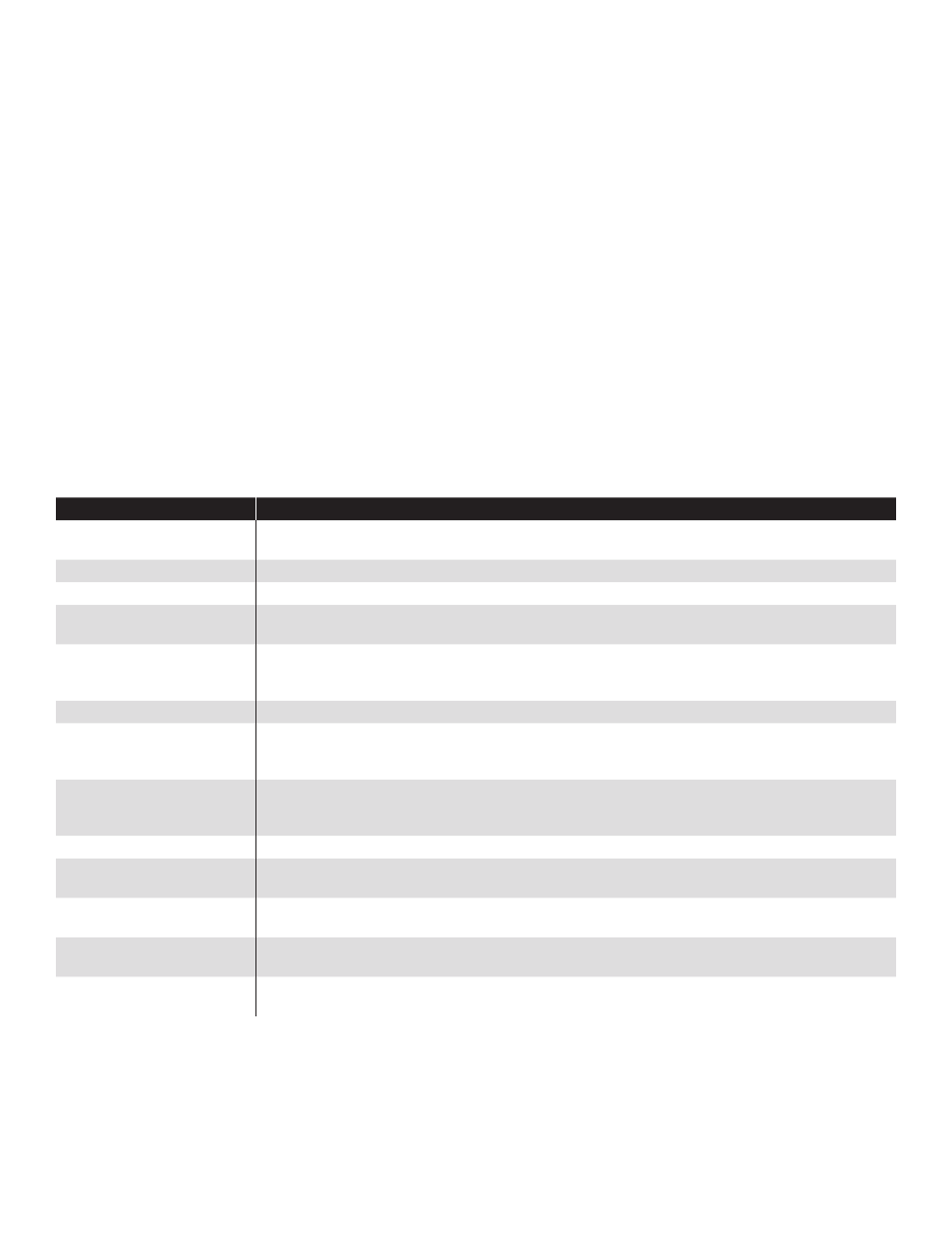

Learn Messages

Learn Message

Description

Existing Vacuum Detected

The Learn Process was started with .5" Hg or more existing in the containment. The Learn Process

needs to be restarted at 0" Hg.

Learned

The containment has been Learned with no errors.

Learning Decay Curve

Displayed during the Learn Process to indicate that the calibrated leak decay curve is being recorded.

Learning Evacuation

During the Learn Process, SCM is recording the time and vacuum levels while evacuating the

containment.

Failed to Reach Target

Vacuum / Time Limit

Exceeded / Pre-Existing Leak

A vacuum leak is present when the leak generator should not be open.

No Leak Detected

Vacuum level is constant or has risen while Learning the decay curve.

No Leak Detected/Time Limit

Exceed

The leak valve was opened when prompted, but the leak valve was closed before the Learn Process

was completed. Restart the Learn Process and open the leak valve when prompted. Close the leak

valve after the Learn Process has completed.

Not Learned

The containment has been programmed, but the containment has never been Learned. Refer to the

SCM Learn Process section to Learn the containment. Follow all Warnings, Cautions, and Notes prior

to Learning the containment.

Open Leak Valve

This is a required step during the Learn Process. When shown, open the leak generator.

Pump Request Ignored

SCM sent a request to start the STP, but the TPI or the relay module didn’t send confirmation that the

STP was running. The STP may be used or disabled by other applications.

Sensor Malfunction

This message is displayed if the containment is enabled in the setup, not Learned, and the sensor

was disconnected. Verify sensor wiring.

Exceed Time Limit to Reach

Target Vacuum

Evacuation Learning exceeds the limit.

Time Out for Leak Valve Not

Opened

The leak valve is not open during the Learn Process. Restart the Learn Process and open the leak

valve when prompted to by the console.