Franklin Fueling Systems TS-550/TS-5000 consoles Secondary Containment Monitoring User Manual

Page 13

10

Turbine Pump Interface (TPI) Applications (Alternate STP Control)

TPI is an alternative to using the Relay Module to actuate an STP on demand (from a dispenser request or SCM). Just

as with using a relay channel, this method will provide positive pump shutdown on alarm (if that option is chosen in the

setup). When using the standard TPI feature of the console to control a STP, be sure to map the SCCM vacuum sensor

as an “Input” for the STP that it is connected to (as shown in the TPI table). This will allow the SCM application to actuate

the STP when it is necessary to regulate the vacuum levels in the containment. For further information and instructions on

programming TPI and/or Relay Modules to control a STP, please refer to the T5 FMS Programming Guide (p/n 000-2142).

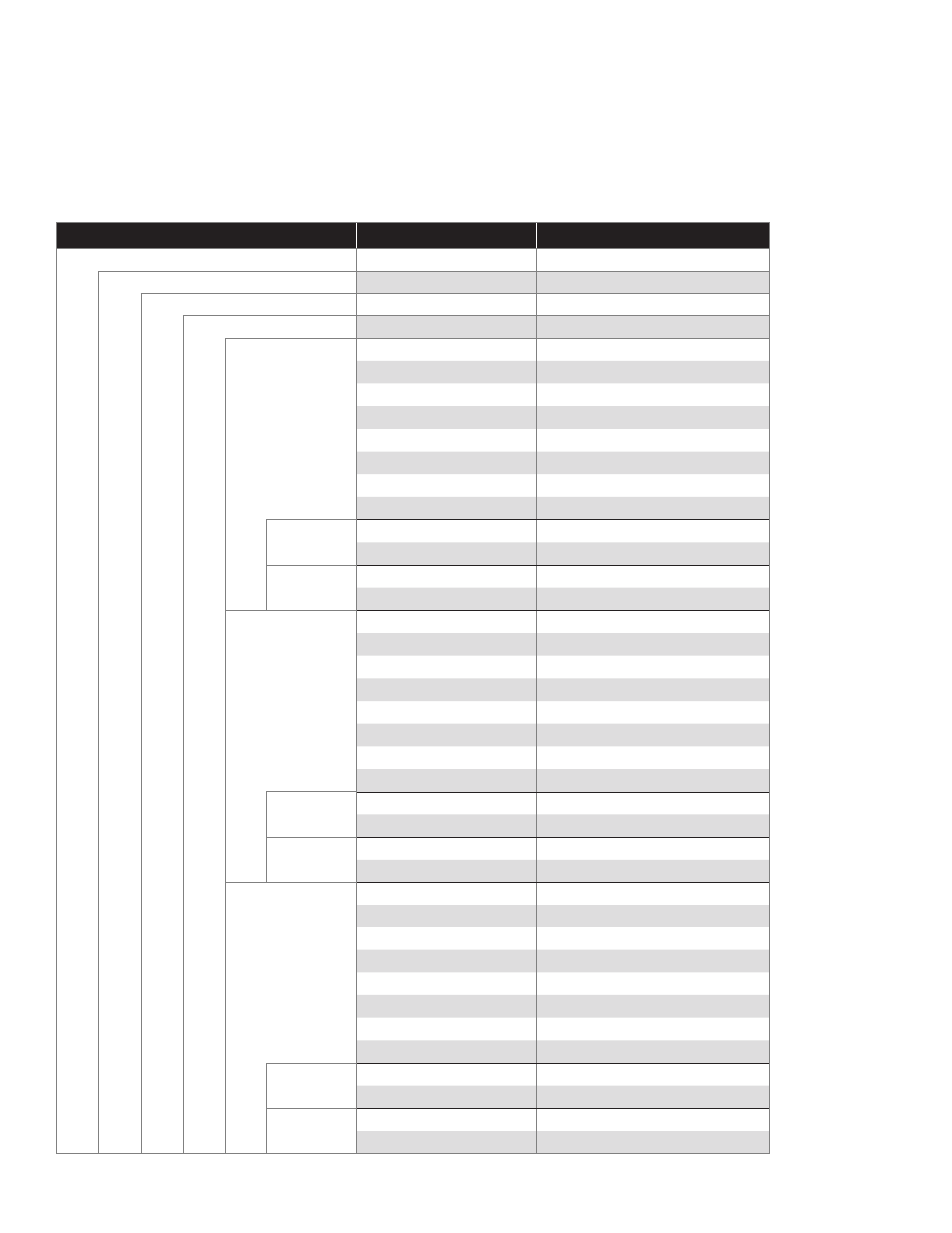

Example: TPI Setup

Group Name

Parameter Name

Parameter Value

Power Supply

RS-485

Enable Interface Yes

TS-TPI

Enable Interface Yes

Controllers

A

Number of Controllers ‘#’

Controller ‘#’

Name Unleaded Controller

Enabled Yes

Type Mag/Eco

Address 1

Group 0

Tank 1

Height 5.00 in

Number of inputs 2

Input 1

Type AC Input Module

Channel Unleaded Hook Signal

Input 2

Type 4-20mA Input Module

Channel Unleaded SCM Vacuum Sensor

Controller ‘#’

Name Premium Controller

Enabled Yes

Type Smart I

Address 2

Group 0

Tank 2

Height 5.00 in

Number of inputs 2

Input 1

Type AC Input Module

Channel Premium Hook Signal

Input 2

Type 4-20mA Input Module

Channel Premium SCM Vacuum Sensor

Controller ‘#’

Name Diesel Controller

Enabled Yes

Type Smart III

Address 3

Group 0

Tank 3

Height 5.00 in

Number of inputs 2

Input 1

Type AC Input Module

Channel Diesel Hook Signal

Input 2

Type 4-20mA Input Module

Channel Diesel SCM Vacuum Sensor