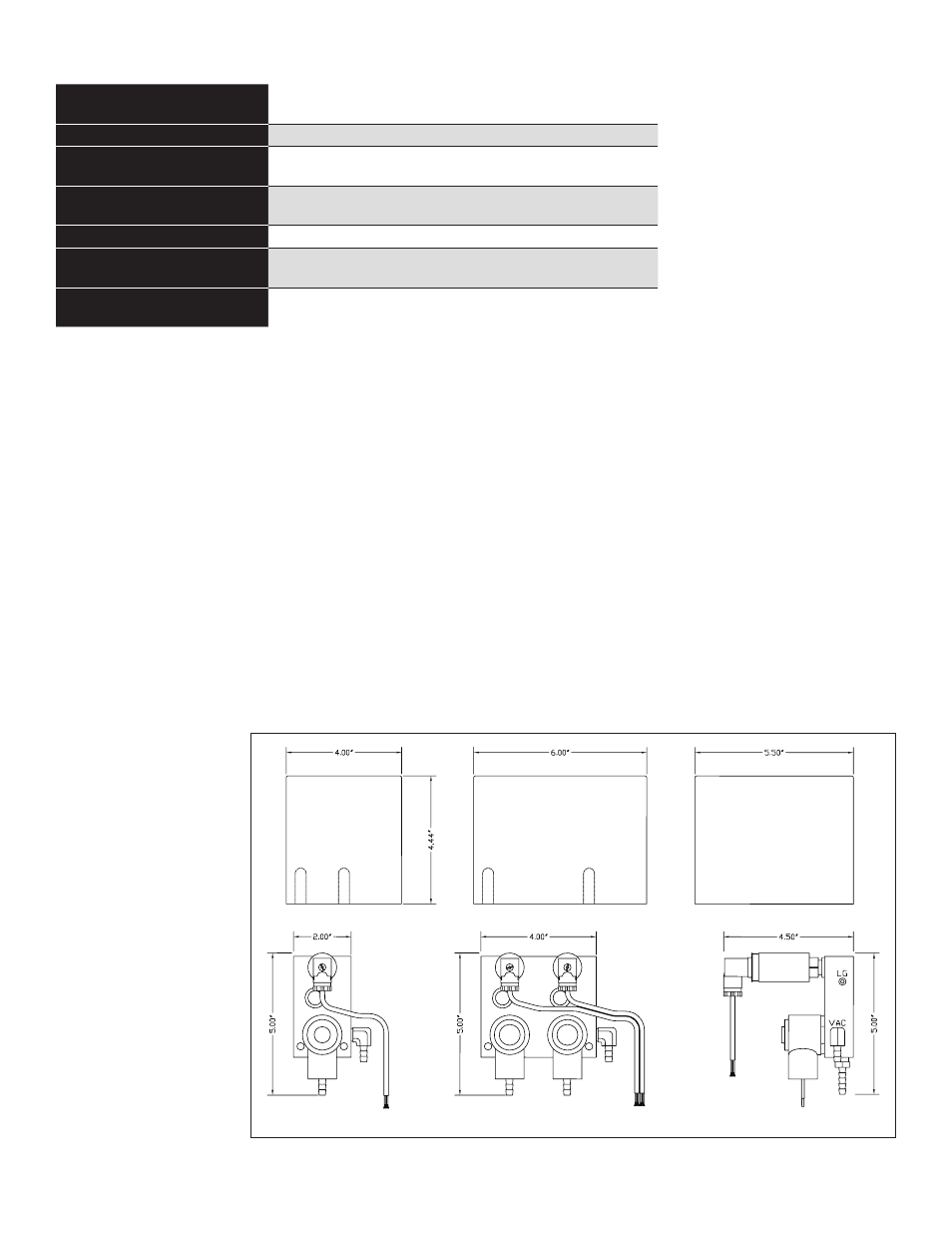

Site requirements, Figure 2 – sccm 1 and sccm 2 dimensions – Franklin Fueling Systems TS-550/TS-5000 consoles Secondary Containment Monitoring User Manual

Page 6

3

Site Requirements

Total Containment Volume*

Minimum - 0.25 gallons (1 L)

Maximum - 500 gallons (1879 L)

*Refer to manufacturers’ installation

guides or data sheets to calculate

containment area volumes.

**All containment areas MUST be

compatible with the vacuum levels

listed.

Normal Operating Vacuum

2" – 6" Hg (1 – 3 PSIG)

Pre-Programmed Maximum

Shutdown (Alarm Condition)

9" Hg (4.5 PSIG)

Mechanical Relief Valve

Vacuum**

10" Hg (5 PSIG)

Jumper Tubing

Use only supplied vacuum tubing

Vacuum Sensor Wiring

Belden No. 87761(0.12" OD) to 400 ft.

Belden No. 89182(0.31" OD) to 500 ft. (maximum distance)

Solenoid Wiring

600 V, 18 AWG minimum, UL approved

refer to ANSI/NFPA70 or CEC electrical codes

Note: SCM should be tested annually after installation.

The term containment (in secondary containment) refers to the interstitial spaces of double walled piping, sumps and

tanks that serve as a secondary containment if the primary containment is damaged.

Individual containment sections of a given product pipeline may be jumpered together via a vacuum line to form one larger

single containment. An example of ‘jumpered’ containment spaces is the secondary containment layer of product piping

from the turbine containment to the first dispenser, and then jumpered to the secondary containment layer of the same

product piping on the other side leading to the next dispenser containment area.

Several containment areas may be grouped together and used with a single Secondary Containment Control Module (TS-

SCCM). No more than four (4) SCM groups should be used per pump siphon. The combination of any containment group

may not exceed the volume limits listed for SCM.

Note: DO NOT jumper tank interstitials with other tank interstitials or other containments.

Note: DO NOT jumper containment areas of unlike product pipelines together.

Note: If grouping multiple containment areas together, the installer will need to purchase and use the vacuum hose,

fittings, and clamps to secure the connection as specified by FFS.

Note: Both intrinsically safe and explosion proof conduits need to be available inside of the turbine containment for the

TS-SCCM.

Available Configurations

Refer to Franklin Fueling

Systems’s current Fuel

Management Systems

Product Catalog for

a complete listing

of the current SCM

configurations offered.

Note: The SCCM 1 (as

pictured in Figure

2) can monitor one

containment group

and the SCCM

2 can monitor

two containment

groups.

TS-SCCM/1

TS-SCCM/2

TS-SCCM Side View

Figure 2 – SCCM 1 and SCCM 2 Dimensions