Pre-operational containment testing, Required equipment, Containment tightness and continuity test – Franklin Fueling Systems TS-550/TS-5000 consoles Secondary Containment Monitoring User Manual

Page 17

14

Pre-Operational Containment Testing

Pre-operational containment tests determine the tightness of the entire SCM system, including TS-SCCM and inter-

connect tubing. These tests consist of two separate procedures: Containment Tightness Tests and STP Siphon Tests. The

first procedure, Containment Tightness Testing, will determine whether the containment areas chosen to be monitored are

tight. The second, STP Siphon Testing, will determine if the STP is capable of creating enough vacuum for proper SCCM

operation.

The Containment Tightness Testing procedure assumes that all STP’s and pump controllers have been installed, wired,

calibrated, and are operational and in accordance with their respective installation and operation procedures. It also

assumes that all T5 FMS console programming has been completed.

Warning

DO NOT apply vacuum or pressure until consulting the containment manufacturer on the maximum

allowed vacuum or pressure levels.

Warning

DO NOT use equipment that is not explosion proof in classified areas. Keep vacuum pumps

outside class 1, division 1, and class 2 areas. Refer to NFPA 30A, chapter 8.

Caution

DO NOT proceed to the Learn Process until each containment successfully completes

pre-operational testing. Failure to perform these tests or ignoring any failed tests may prevent the

SCM application from detecting a containment fault.

Note: State and/or local laws may require a separate, more stringent containment tightness test. ALWAYS verify and

comply with local regulations.

Note: The STP connected to the SCCM being tested will need to be activated by lifting the appropriate product dispenser

handle. Verify that all STP’s and pump controllers are installed, calibrated and operational.

Required Equipment

• Vacuum Pump (or other vacuum source)

• In-line Regulator

• Shut-off / Isolation Ball Valve

• Two 0" to -30" Hg Vacuum Gauge (2" Hg max. graduation marks)

• T-Fittings (where applicable)

In-Line

Regulator

To Containment

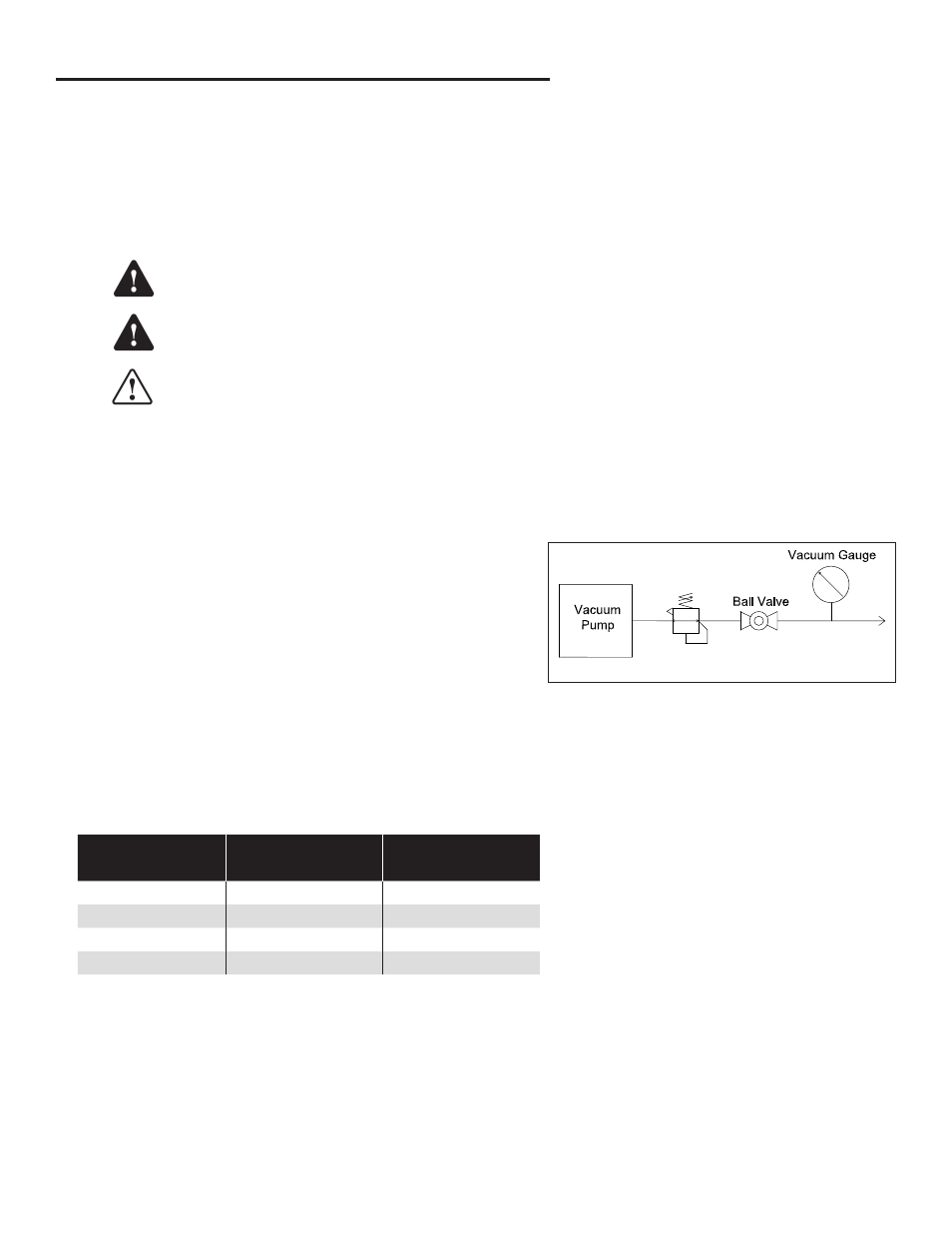

Figure 7 – Vacuum Pump Setup Diagram

Containment Tightness and Continuity Test

Perform the following steps for each SCCM channel.

1. Calculate the approximate containment volume for each area. Consult the secondary containment equipment

manufacturer’s manuals, data sheets, or other official references.

APT SC Pipe Size

Interstitial Volume

(gal/ft)

Interstitial Volume

(gal/100 ft)

1.00" (XP-100-SC)

0.006

0.600

1.50" (XP-150-SC)

0.008

0.800

1.75" (XP-175-SC)

0.009

0.900

2.00" (XP-200-SC)

0.010

1.000

2. Vacuum Gauge Installation

• For Individual DW Turbine and Tank Sump Containments,

connect the vacuum gauge as shown in Figure 7.

• For SC Pipe and Multiple Jumpered Containments,

in addition to the setup shown in Figure 7, connect a vacuum

gauge to the end of the last interstitial space or pipe test boot.