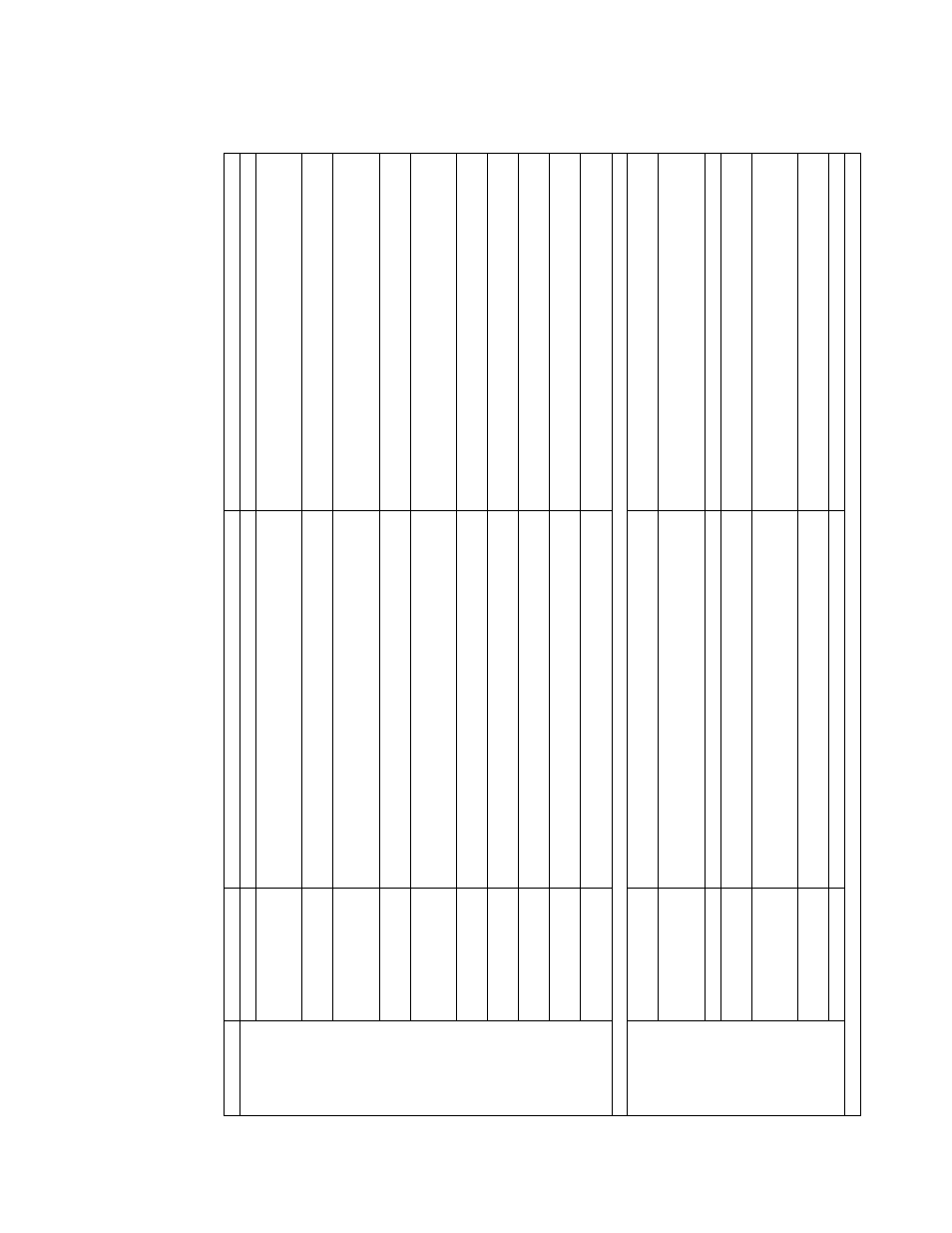

Table 9-1. fault t able – Bell & Gossett 176R0649C Technologic 502 Series Pump Controller User Manual

Page 59

59

Section 9 Start Up Troubleshooting

Sy

m

pto

m

Po

ssi

bl

e

cau

se

Test

So

lu

tio

n

Mi

ss

ing

input

po

w

er

See

st

ar

tup

gu

ide

for

v

ol

tag

e

chec

ks

.

C

or

rec

t v

ol

ta

ge

at

s

our

ce.

Mi

ss

ing

or

o

pen

fus

es

or

c

irc

ui

t

br

eak

er

tr

ippe

d

See

ope

n

fus

es

and

tr

ip

ped

c

irc

ui

t br

eak

er

in

th

is

s

ec

tion

for

pos

si

bl

e

caus

es

.

R

es

et

c

irc

ui

t br

eak

er

.

If

fus

es

, c

hec

k

for

opens

w

ith

po

w

er

rem

ov

ed

fro

m

panel

.

Loos

e

co

nnec

tions

in

pane

l

Per

for

m

pr

e-

st

ar

tup

chec

k

for

loos

e

conn

ec

tio

ns

.

Ti

ght

en

loos

e

conn

ec

tio

ns

in

pa

nel

.

Mi

ss

ing

c

us

tom

er

connec

tions

Mi

ss

ing

c

us

tom

er

c

onnec

tions

c

an

caus

e

the

s

af

et

y

ci

rc

ui

t or

st

ar

t s

igna

l t

o

be

op

en.

See

cus

tom

er

c

onnec

tions

and

m

ak

e

sur

e

al

l a

pp

lic

ab

le

connec

tions

ar

e

m

ade

or

jum

per

s

ins

tal

led

es

pec

ial

ly

cus

tom

er

int

er

loc

k.

Loos

e

cus

tom

er

connec

tions

C

hec

k

al

l c

us

tom

er

c

onnec

tions

for

ti

ght

nes

s.

Lo

os

e

cus

tom

er

c

onnec

tions

c

an

ac

t l

ik

e

an

ope

n

ci

rc

ui

t.

Ti

ght

en

loos

e

cus

tom

er

c

onnec

tions

.

C

us

tom

er

w

ires

inc

or

rec

tly

ter

m

inat

ed

See

cus

tom

er

c

onnec

tion

d

raw

in

g

an

d

m

ak

e

sur

e

w

ire

s

ar

e

connec

te

d

to

cor

rec

t t

er

m

inal

s.

C

or

rec

t an

y

w

ro

ng

con

nec

tions

.

Thi

s

coul

d

pot

en

tia

lly

cas

e

dam

age

to

pan

el

.

Im

pr

oper

v

ol

tage

ap

plie

d

See

pr

e-

sta

rtu

p c

he

ck

li

st.

C

or

rec

t v

ol

ta

ge

m

is

m

at

ch.

T

hi

s

coul

d

pot

ent

ial

ly

dam

age

pane

l c

au

tio

n

on

appl

yi

ng

po

w

er

rec

om

m

ended.

Po

w

er

c

onnec

tions

connec

te

d

w

ron

g

See

pre

-s

tar

tup

c

hec

k

lis

t t

o

see

if

m

ot

or

and

po

w

er

le

ads

w

er

e

sw

ap

ped

.

C

or

rec

t an

y

w

ro

ng

con

nec

tions

.

Thi

s

coul

d

pot

en

tia

lly

cas

e

dam

age

to

pan

el

.

Po

w

er

di

sc

on

nec

t

open

Ver

ify

that

di

sc

on

nec

t or

c

irc

ui

t br

eak

er

is

c

los

ed.

C

or

rec

t an

y

w

ro

ng

con

nec

tions

.

Th

is

c

oul

d

pot

en

tia

lly

cas

e

dam

age

to

pan

el

.

O

per

at

or

s

w

itc

hes

of

f

Ver

ify

that

oper

at

or

d

ev

ic

es

ar

e

in

op

er

at

ing

pos

iti

on

per

st

ar

tup

pr

oc

edur

es

.

Se

t s

w

itc

he

s to

c

or

re

ct p

os

iti

on

.

N

o

func

tio

n

O

L

tri

pp

ed

A

tri

ppe

d

O

L

w

ill

di

sab

le

th

e

m

ot

or

fr

om

runni

ng.

V

er

ify

th

at

O

L

rel

ay

is

in

nor

m

al

oper

at

ing

pos

iti

on

per

m

anual

.

Per

for

m

pr

e-

st

ar

tup

chec

k

lis

t an

d

set

O

L

per

ins

truc

tio

ns

.

Im

pr

oper

v

ol

tage

ap

plie

d

See

pr

e-

st

ar

tup

c

hec

k

lis

t a

nd

cor

rec

t i

f w

ron

g.

C

or

rec

t v

ol

ta

ge

m

is

m

at

ch.

T

hi

s

coul

d

pot

ent

ial

ly

dam

age

pane

l c

au

tio

n

on

appl

yi

ng

po

w

er

rec

om

m

ended.

Po

w

er

c

onnec

tions

connec

te

d

w

ron

g

Mot

or

and

line

vo

lta

ge

sw

apped

.

M

ak

e

sur

e

the

lin

e

in

an

d

m

ot

or

out

ar

e

on

th

e

cor

rec

t t

er

m

inal

s.

S

ee

pr

e-

st

ar

tu

p

chec

k

lis

t.

C

or

rec

t an

y

w

ro

ng

con

nec

tions

.

Thi

s

coul

d

pot

en

tia

lly

cas

e

dam

age

to

pan

el

.

Po

w

er

gr

ou

nd

faul

t

C

hec

k

m

ot

or

and

pa

ne

l p

ow

er

w

ires

to

gr

ound.

El

im

inat

e

an

y

gr

ou

nd

faul

ts

det

ec

ted.

Phas

e

to

phas

e

shor

t

Mot

or

or

pan

el

has

a

s

hor

t phas

e

to

phas

e.

C

hec

k

m

ot

or

and

pane

l p

has

e

to

phas

e

for

s

hor

ts

.

El

im

inat

e

an

y

sh

or

ts

det

ec

ted.

Mot

or

ov

er

lo

ad

Mot

or

is

o

ver

load

ed

for

the

app

lic

at

ion

.

Per

for

m

s

tar

tup

an

d

ver

ify

m

ot

or

c

ur

rent

is

w

ith

in

spec

ifi

cat

io

ns

.

If

m

ot

or

c

ur

rent

is

ex

ceed

ing

nam

epl

at

e

FLA

red

uc

e

th

e

loa

d

on

the

m

ot

or.

D

riv

e

ov

er

load

D

riv

e

is

o

ver

loa

ded

for

the

app

lic

at

ion

.

Per

for

m

s

tar

tup

an

d

ver

ify

dr

iv

e

cur

rent

is

w

ithi

n

spec

ifi

cat

io

ns

.

If

not

re

duc

e

the

lo

ad

on

the

m

ot

or

.

O

pen

po

w

er

fus

es

or

cir

cu

it

br

eak

er

tr

ip

Loos

e

co

nnec

tions

Per

for

m

pr

e-

st

ar

tup

chec

k

for

loos

e

conn

ec

tio

ns

.

Ti

ght

en

loos

e

conn

ect

io

ns.

Table 9-1. Fault T

able