Warning, Control wiring, Drive control terminals – Bell & Gossett 176R0649C Technologic 502 Series Pump Controller User Manual

Page 18

18

Control Wiring

• It is recommended that control wiring is

rated for 600 volts for 480 V and 600 V

drives and 300 volts for 200-240 V drives.

• Isolate control wiring from high power

components in the drive.

WARNING

!

r

un

input

powEr

,

motor

wiring

and

control

wiring

in

tHrEE

sEparatE

mEtallic

conduits

or

racEways

for

HigH

frEquEncy

noisE

isolation

. f

ailurE

to

isolatE

powEr

,

motor

and

control

wiring

could

rEsult

in

lEss

tHan

optimum

drivE

and

associatEd

EquipmEnt

pErformancE

.

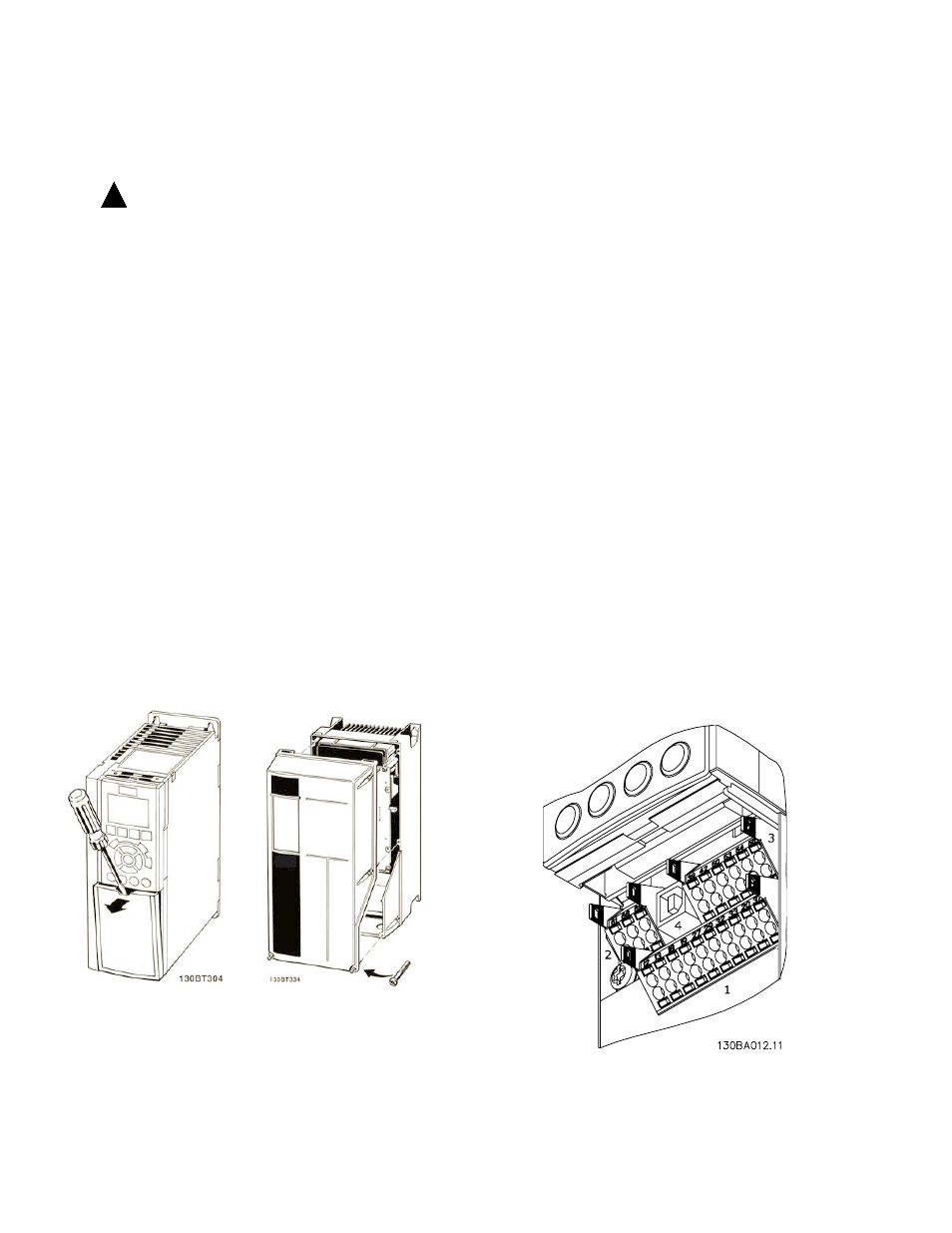

Figure 3-8. Control Terminals Access

Definitions of the drive terminals are summarized in

Table 3-3. Figure 3-9 shows the removable controller

connectors and terminals.

•

Connector 1 provides four programmable

digital inputs, two additional digital terminals

programmable as input or output, a 24 VDC

terminal supply voltage, and a common for

optional customer supplied 24 VDC voltage.

•

Connector 2 is for the serial

communications EIA-485 connector with

terminal 68 (+) and 69 (-).

•

Connector 3 provides two analog inputs,

one analog output, 10 VDC supply voltage,

and commons for the inputs and output.

•

Connector 4 is a USB port available for

use with the MCT-10 drive programming

software.

• Also provided are two Form C relay outputs

that are in various locations depending upon

the controller configuration and size.

Drive Control Terminals

Figure 3-9. Drive Control Terminals

Control Wiring Access

• For units 5 hp or less (208 V) and 10 hp or

less (480 V), remove access cover plate with

screw driver. (See Figure 3-8.)

• For larger size units, remove front cover of

unit to access internally mounted control

terminals. (See Figure 3-8.)