Lifting, Cooling, Mechanical installation – Bell & Gossett 176R0649C Technologic 502 Series Pump Controller User Manual

Page 13

13

Lifting

Check the weight of unit to determine the safety of the

lifting method. (See the mechanical drawing supplied

with the equipment for unit weight.) Ensure that the

lifting device is suitable for the task. If necessary, plan

for a hoist, crane or forklift with appropriate rating to

move the units. For lifting, use hoist rings provided.

Cooling

• Mount the controller and panel vertically.

• Option panels rely on the ambient air

for cooling. It is important to observe the

limitations on ambient air temperature.

Derating start above 104

o

F (40

o

C) and 3300

feet elevation above sea level.

Mechanical Installation

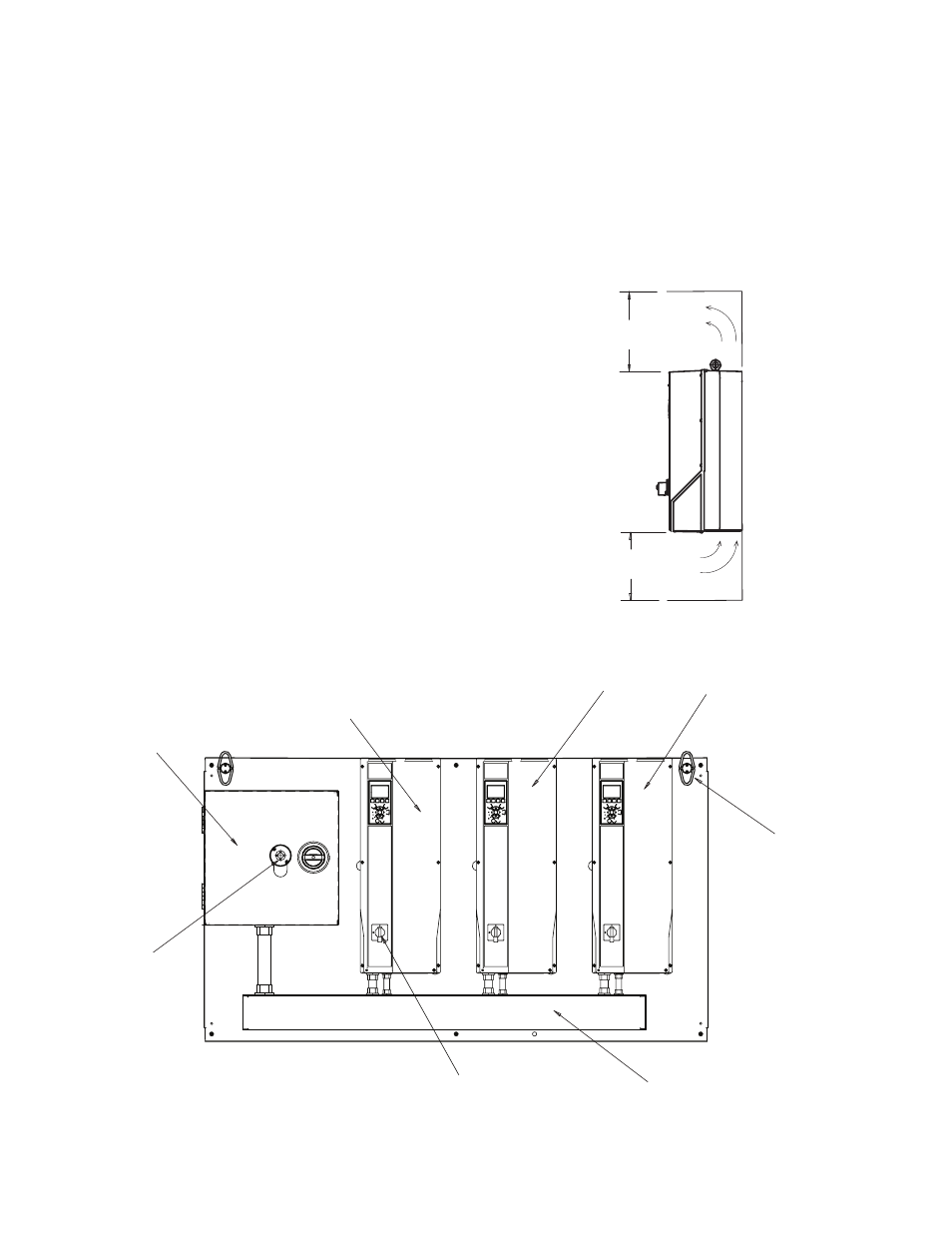

• Top and bottom clearance is required for

cooling (Figure 3-2). Generally, 4 to 10

inches (100 to 250 mm) minimum clearance

is required, depending upon the hp of the

unit. See the mechanical drawing shipped

with the unit for specific requirements.

4.0 in min.

CEILING

FLOOR

AIRFLOW

4.0 in min.

AIRFLOW

Figure 3-2. Cooling Airflow

Figure 3-3. Typical Unit Components

Input power panel

Master drive

Follower 1

Follower 2

Input power raceway to VFDs

Drive disconnect

Mains (line)

disconnect

Hoist ring

Lift unit by

hoist ring only

- 10 001 247 R3 TechnoForce Package System (36 pages)

- 10 001 265R5 TechnoForce Pump Controller (76 pages)

- 10-001-275 XLS Integrated Pump Controller (57 pages)

- 10-001-278 XLS Integrated Pump Controller (44 pages)

- 193 TECHNOVAR VARIABLE SPEED PUMP CONTROLLER AND INTEGRATED AJUSTABLE FREQUENCY DRIVE (78 pages)

- 210667C Z-4 (2 pages)

- 210668B Z-4B (6 pages)

- 211013D PSE 800 M Low Water Cut-off (20 pages)

- MM 217L Series 150S and 157S Low Water Cut-Offs/Pump Controllers (12 pages)

- Iron & Bronze Booster Pumps Series 100 (4 pages)

- P2001487 Technologic Pump Controller (93 pages)

- P2000642B i-ALERT Condition Monitor (18 pages)

- P80922A Zone Trol Pump Controller ZT-1X (4 pages)

- P80925B Zone Trol Zone Pump Controller ZT-2 (6 pages)

- S11574C Heat Transfer Package with Air Separation (8 pages)

- S11865A TECHNOLOGIC 1100 SERIES PUMP CONTROLLER (4 pages)

- 70E Multiple Pump & Control Pressure Booster Systems (28 pages)

- S12260 R4 Genuine Bell & Gossett Replacement Seal Kit (1 page)

- S12596B Technologic 350 Pump Controller (24 pages)

- S13213A MiniBooster Pumping Package (10 pages)

- S13641B Technologic 5500 Series Pump Controller (38 pages)

- S13654B Technologic 5500 Series Pump Controller (31 pages)

- S14141B 70X Multiple Pump Pressure Booster Systems (12 pages)

- S14333 Technologic 5500 Series ZoneSav Controller (38 pages)

- S14334B Technologic 5500 Series Variable Primary Pump and Valve Controller (54 pages)

- S14362C Glycol Make-up Unit (10 pages)

- S14367B Technologic Constant Speed Pump Controller (44 pages)

- 6 71 075 003A Autocirc Instant Hot Water Pump Models e3-4/BDPQC (8 pages)

- 6 71 075 110A The ecocirc auto/vario Series Pumps (4 pages)

- 6 71 075 111A Autocirc Instant Hot Water Pump Model ecocirc 23 5 ACT (8 pages)

- 6 71 075 114A Series e3 SC Solar Circulators (6 pages)

- 6 71 075 115A LS Condensate Removal Pump (6 pages)

- 6 71 075 141B ecocirc wireless Potable Hot Water Recirculation Kit (28 pages)

- A 00 091 365A Series e3 4/e3 6 Instant Hot Water Recirculating Systems (6 pages)

- A 00 091 391A Automatic Plug-In Timer for e³-4/e³-6 Circulators (2 pages)

- A91590B DB-3/4″ Differential By-Pass Valve 3/4″ x 3/4″ NPT Male Connections Operational Limits (2 pages)

- A91591 Number 98 High Capacity Air Vent 1/2″ Female NPT Connection Operational Limits (3 pages)

- AC8584D Series HSCS Base Mounted Centrifugal Pumps (32 pages)

- IM207R00 Series 3530 (24 pages)

- IM228R04 e-SV (64 pages)

- MN 414 AC Submersible Pump Motors (16 pages)

- P0002560 Wireless Module and RS-485 Module (8 pages)

- P15758C Replacing the Bearing Frame Assembly or Pump Shaft (5 pages)

- P15776H Little Red Booster Pumps (4 pages)