3B Scientific Critical Point Apparatus User Manual

Page 19

5

ϑ

⋅

−

⋅

+

+

=

ϑ

C

p

C

s

s

s

p

e

0

(9)

By substituting in equation 4, we get:

(

)

0

0

0

=

⋅

−

ϑ

+

ϑ

⋅

ϑ

⋅

β

−

⋅

β

+

+

⋅

ϑ

R

n

A

p

s

s

p

p

e

(10)

If we take several readings at various temperatures

and pressures, we can calculate the term:

(

)

∑

=

ϑ

⎟⎟

⎠

⎞

⎜⎜

⎝

⎛

⋅

−

ϑ

+

ϑ

⋅

ϑ

⋅

β

−

⋅

β

+

+

⋅

=

n

p

R

n

A

p

s

s

p

Q

1

i

2

0

i

i

0

i

i

(11)

The free parameters s

0

,

β

P

,

β

ϑ

and n should be appro-

priately selected so that the value of Q is reduced to a

minimum.

Additionally required (see also chapter 8):

1 Compressor or

bicycle pump and valve

1 Bath/circulating

thermostat

U14400

1 Dig. quick-response pocket thermometer U11853

1 Type K NiCr-Ni immersion sensor,

-65°C-550°C

U11854

2 Silicone tubes, 1 m

U10146

1 l Anti-freeze fluid with corrosion-inhibiting additive

for aluminium engines (e.g., Glysantin® G30 ma-

nufactured by BASF)

Conducting the calibration:

•

Connect the circulation thermostat as described

in chapter 8 and fill it with the water/anti-freeze

mixture.

•

Connect the plastic tube (3-mm internal diameter)

to the 1/8" gas connection fittings.

•

Open the regulating valve.

•

Wind the handwheel outwards, making the piston

move till it reaches say the 46.0 mm position.

•

Use a compressor or a bicycle pump to create an

excess air pressure of approx. 3-8 bar in the

measuring cell.

•

Shut the regulating valve.

•

To record measurements, vary the volume in the

measuring cell or the temperature of the thermo-

stat and wait till a stationary equilibrium has

been attained. Then take a pressure reading.

•

Use appropriate adjustment software to set the s

0

,

β

P

,

β

ϑ

and n parameters so that the quadratic

equation for the errors Q is reduced to a mini-

mum (see equation 11).

•

If you like, you can adjust the vernier scale

around s

0

so that this correction is not necessary.

With the set parameters, it is possible to calculate the

“effective” piston displacement s from the measured

displacement s

e

using Equation 9 and then to calcu-

late the calibrated measuring cell volume using Equa-

tion 8.

Sample measurements:

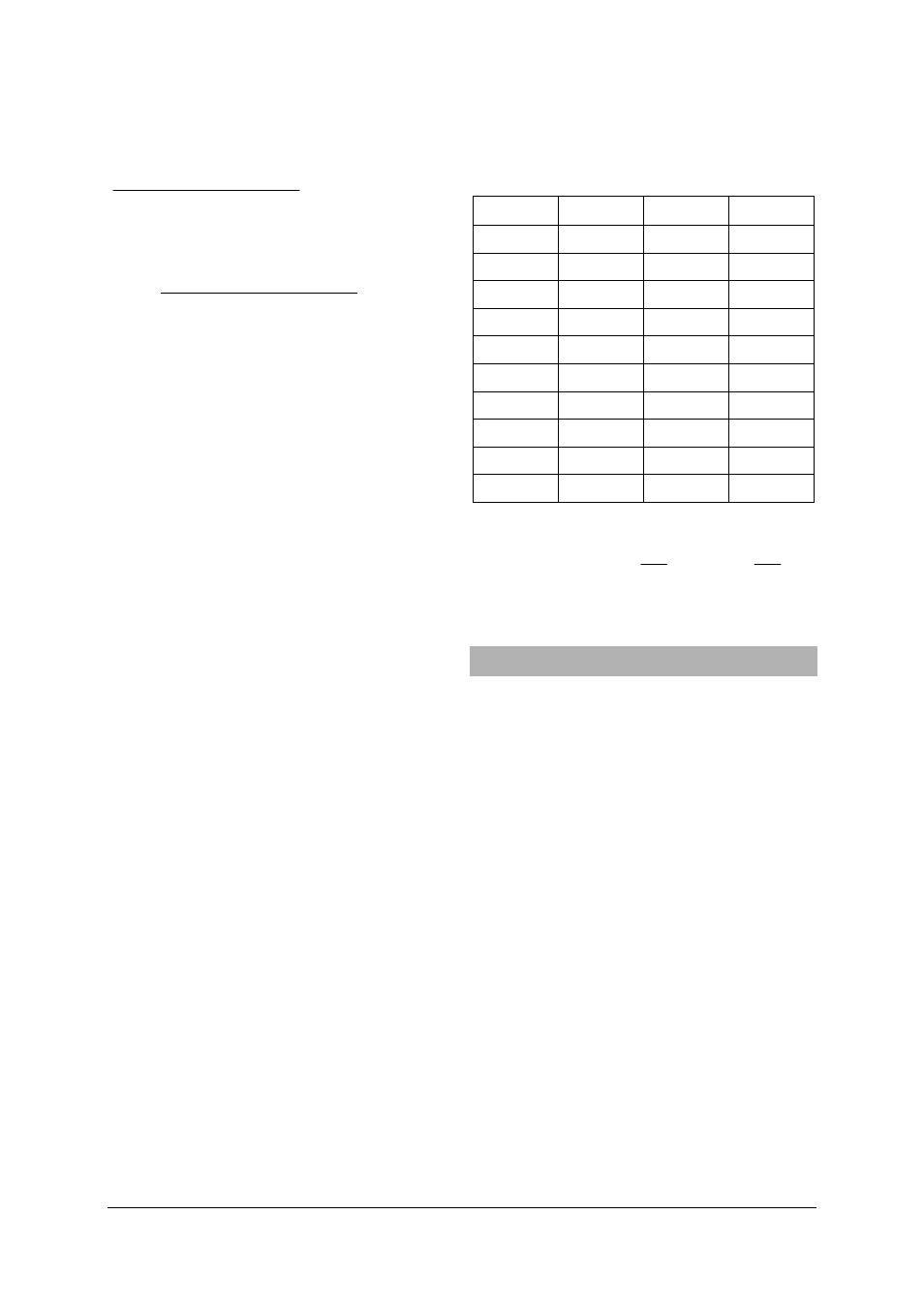

Table 1: Measured values for calibration

i s

e

/ mm

ϑ

p / bar

1 40.0

20.0°C

6.6

2 20.0

20.0°C

12.4

3 10.0

20.0°C

23.3

4 5.0

20.0°C

41.8

5 3.5

20.0°C

53.9

6 5.0

20.0°C

41.8

7 5.0

10.0°C

38.9

8 5.0

30.0°C

45.3

9 5.0

40.0°C

49.0

10 5.0

50.0°C

53.5

The following parameter values are obtained:

s

0

= 0.19 mm,

bar

mm

023

0

P

.

=

β

,

grd

mm

034

0.

=

β

ϑ

and

n = 0.00288 mol.

7. Filling with test gas

7.1 Handling of sulphur hexafluoride:

Sulphur hexafluoride (SF

6

) is a non-toxic gas and is

absolutely safe for humans. The MAC value for danger

of suffocation on account of oxygen deprivation is

1000 ppm. That is equivalent to 6 filled measuring

cells per 1 m

3

of air.

However, SF

6

is extremely harmful to the environment

and can give rise to a greenhouse effect 24,000 times

stronger than CO

2

. Therefore, do not allow large quan-

tities to be released into the environment.

7.2 Gas connection via fixed pipes:

Additionally required:

1 SF

6

gas cylinder with manufacturer’s/supplier’s rec-

ommended gas fittings/valves, e.g. SH ILB gas cylinder

and Y11 L215DLB180 regulating valve from Airgas

(www.airgas.com).

1 Pipes with outer diameter of 1/8" and, if necessary,

adapters, e.g. from Swagelok (www.swagelok.com).

1 open-end spanner (13 mm), 1 open-end spanner

(11 mm)

According to the principles of “good laboratory prac-

tice”, it is recommended to utilise a gas supply via

fixed pipes, especially if the equipment is regularly in

operation.