VEGA VEGAPULS 81 User Manual

Page 48

48

VEGAPULS 64 and 81

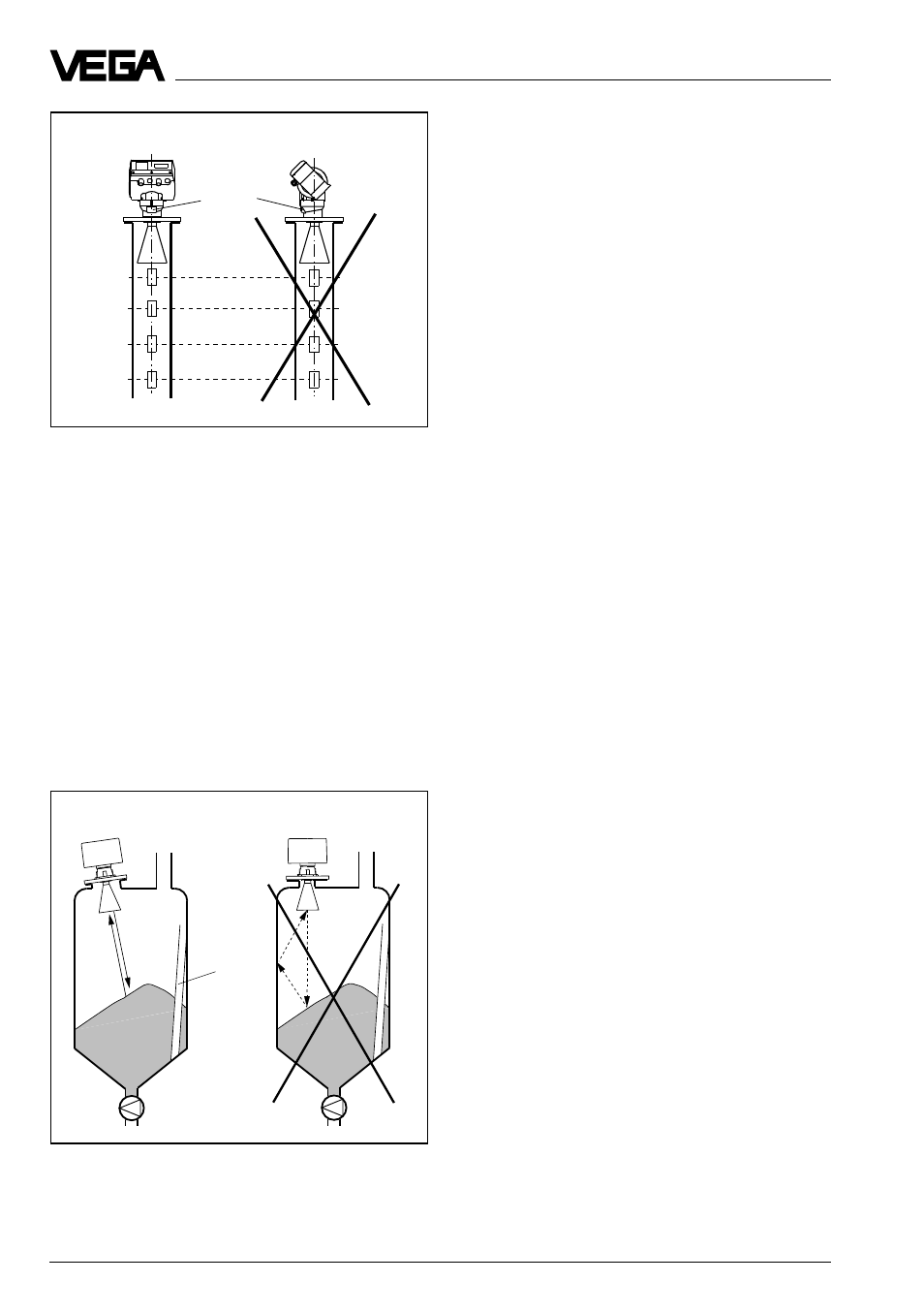

Wrong directing to the product surface

A directing of the sensor which does not point

to the product surface will cause a weak

measuring signal. If possible direct the sensor

axis vertically to the product surface, to reach

optimum measuring results.

Mounting and installation: Installation fault

Sensor too close to the vessel wall

If the radar sensor is mounted too close to the

vessel wall, strong interfering signals can be

caused. Build-up, rivets, screws or weld joints

superimpose their echoes to the useful signal

or useful echo. Hence note a sufficient dis-

tance of the sensor to the vessel wall.

In case of good reflection conditions (liquids

without vessel installations) we recommend

you select the sensor distance so that there is

no vessel wall within the inner emission cone.

For liquids with worse reflection conditions it is

useful that there are also no interefering instal-

lations within the outer emission cone. Note

chapter “2.1 General installation instructions“.

Foam generation

Strong, dense and creamy foam on the prod-

uct can cause faulty measurements. Provide

measures to avoid foam or measure in a by-

pass pipe. Check if necessary the use of

another measuring principle e.g. capacitive

electrodes or hydrostatic pressure transmit-

ters.

Direct sensor vertically to the product surface

Correct

Wrong

VEGAPULS 81 on a surge pipe: The polariza-

tion direction is in line with the casting nose.

The sensor must be directed with the castin

nose to the rows of holes or openings

Casting nose

Ladder

Correct

Wrong