Receipt of goods and storage, Preparation and installation – M&C TechGroup SP2020-H_C_I_BB_F Operator's manual User Manual

Page 12

12

Gas sampling and gas conditioning technology

2-1.1.6.1-ME

10

RECEIPT OF GOODS AND STORAGE

The gas sample probe and any special accessories should be removed carefully from the packag-

ing and checked immediately for completeness against the delivery note.

Check the goods for any damage incurred during transport and if necessary inform your transport

insurer of any damage.

The gas sample probe is normally delivered in two packaging units:

1. The gas sample probe with the screws, nuts and flange seal required for mounting.

2. Sample tube or prefilter, if applicable with extension tube.

N O T E !

The equipment should be stored in a protected, frost-free room!

11

PREPARATION AND INSTALLATION

Select the optimal sampling point in accordance with the generally applicable guidelines or consult

the competent persons.

Locate the sampling point in such a way that there is adequate space for inserting and removing the

probe and pay attention to the insertion length of the probe tube.

Make certain that the probe is easily accessible so that you can carry out any subsequent mainte-

nance work without trouble.

Locate the probe connections in such a way that the connections' temperature is always above the

acid dew point in order to avoid corrosion and blockage problems. If this is not possible, a heated

SP35/SP30 probe tube is recommended for cold connections.

If the ambient temperature in the area of the connections is >80°C as a result of radiated heat, then a

radiated-heat deflector must be mounted to protect the probe.

The connection's mounting flange connection should comply with DN65 PN6. If other connection

sizes are required, a special adapter flange /S010 can be supplied as an option.

Instead of flange connection mounting, the probe can also be mounted using an R2" adapter /S01 on

a corresponding threaded sleeve connection. This adapter can be supplied.

The necessary minimum flange size and the minimum connection diameter depends on the diameter

of the probe tube or prefilter used.

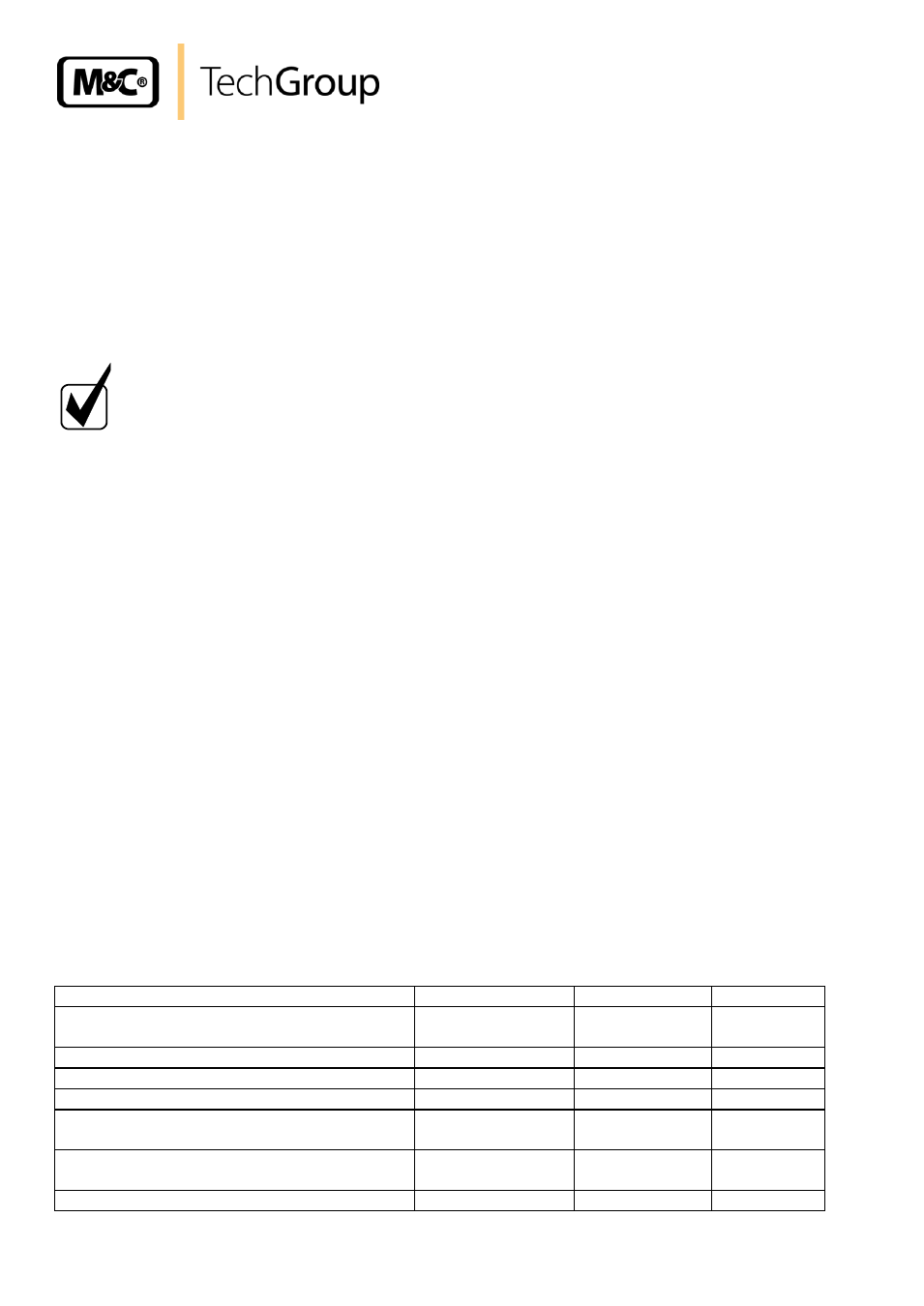

Before mounting, the probe must be adjusted to the existing operating conditions.

The existing operational parameters are to be checked accordingly prior to commencing

mounting work.

Under / over pressure situation

mbar bar

Process temperature

°C

Min.

°C

Max.

Dust loading

g/m³

Dust composition - grain size

µm

Gas composition

corrosive

toxic

explosive

Which parameters should be measured,

e.g. O

2

, CO, SO

2

, NO

X

, ...,

Vol.% mg/Nm³

ppm

Required amount of gas

l/h

Min.

l/h

Max.

Necessary T

90

-time

sec.