Technical data, Description – M&C TechGroup SP2600-H_C_I_BB_F_0,1GF190 Operator's manual User Manual

Page 8

8

Gas sampling and gas conditioning technology

2-1.1.5.1-ME

8

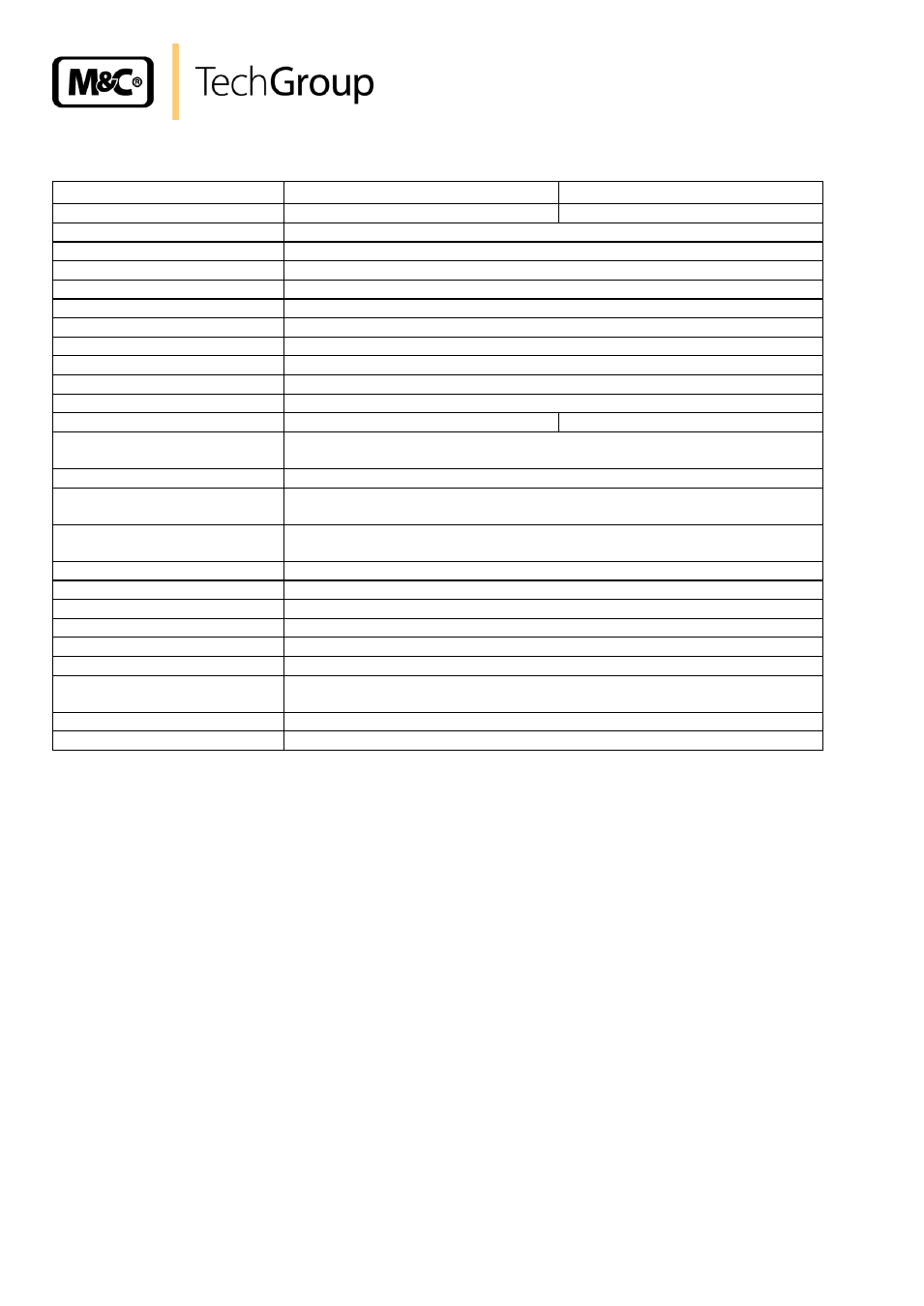

TECHNICAL DATA

Technical Data Series SP

®

SP2600-H/C/I/BB/F/0,1GF

SP2600-H/C/I/BB/F/1K190

Part Number

20 S 3550

20 S 3540

Integrated back purging

Via the filter element

Weather protection cap

yes

Protection terminal box

IP54

EN60529

Materials filter housing

Stainless steel 1.4571, 1.4404

Sealing material

FPM*

Material probe flange sealing Novapress

Sample tube

optionally

Sampling pressure max.

0,4

– 6 bar* abs.

Ambient temperature

-20 °C bis +60 °C*** /PT100, /Fe-CuNi, /Ni-CrNi** = -20 °C bis +80 °C

Filter housing volume

300 cm

3

Filter porosity

0,1 micron

1 micron

Thermostat,

Temperature adjustments

0-180°C* /PT100** /Fe-CuNi** /Ni-CrNi**

Readyness for working

After 40min

Alarm contact for insufficient

temperature

Capacity

250V 3A~, 0,25A=, Switch point:

ΔT 30°C to T

SOLL

Connection sample gas

outlet

1 x ¼“ NPTi* Tube connection Ø 6, 8 or 10 mm**

Backpurge connection (BB/F) Back purging: for tube Ø 8mm

Test gas connection (/C)

Ø 6mm socket piece

Connection stop valve (/I)

Ø 6mm socket piece

Pressure range control air (/I) 3 – 10bar

Power supply

230V 50/60Hz, 800W

or

115V 60Hz, 800W

(fuse 10A)

Electrical connection

terminals; max. 4 mm², 2 x M20 x 1,5 cable gland

Standard electrical

equipment

EN 61010, EN 60519-1

Mounting flange

DN65 PN6, Form B, 1.4571* >DN or ANSI possible**

Weight

approx. 20 kg*

*

Standard

**

Options

*** If there are high ambient temperatures, please choose option PT100 (Part No. 20S9025) or thermoelement Fe-CuNi or

Ni-CrNi (Part No. 20S9027 resp. 20S9028) instead of thermostat regulator. In this case, an additional electronic

temperature regulator is necessary (see also data sheet 2-5.1).

9

DESCRIPTION

The probe has been designed for easy installation, safe operation, easy maintenance and a great

variety of applications. Depending on the particular problem, various sample tubes or preliminary filters

(see data sheets 2-1.1.0.6 and 2-1.1.0.8), which are not included in the scope of supply of the probe,

are screwed into the G3/4"i thread of the filter holder.

The large surface ceramic or glass fibre filter element is installed outside the process area in a

housing with minimal dead space. The probes are designed for replacement of the filter element

without having to remove the sample line so that contamination of the clean gas side is avoided.

Owing to the special design of the heating element of probe SP2600-H..., the entire filter housing

including mounting flange can be heated adjustable to 180°C, thus ensuring reliable operation without

cooling down below the dew point in the external area.