Introduction, Serial number, Application – M&C TechGroup SP2006-H280_DIL Operator's manual User Manual

Page 8: Technical data, N o t e

8

Gas sampling and gas conditioning technology

2-1.1.7.2-ME

6

INTRODUCTION

The M&C gas sample probes type SP2006-H.. are based on the patented probe SP2000-H and are

used for continuous gas sampling and dilution.

6.1

SERIAL NUMBER

The type plates are to be found where the electrical connection box is placed.

N O T E !

Please indicate the serial number of the equipment in case of any question

and when ordering spare parts.

7

APPLICATION

The electrically heated M&C dilution probe is applicable for such processes, where the measuring

procedure or the handling of the process gas requires the dilution of the sample respectively the com-

ponent to be measured. Typical applications are the use with toxic gases, the moisture measurement

and the emission measurement in flue gases.

The M&C dilution probe SP2006-H/DIL... is based on the well tested M&C gas sample probe SP2000-

H. This enables the user to adapt the probe to nearly every application, using for example special filter

techniques or special materials.

8

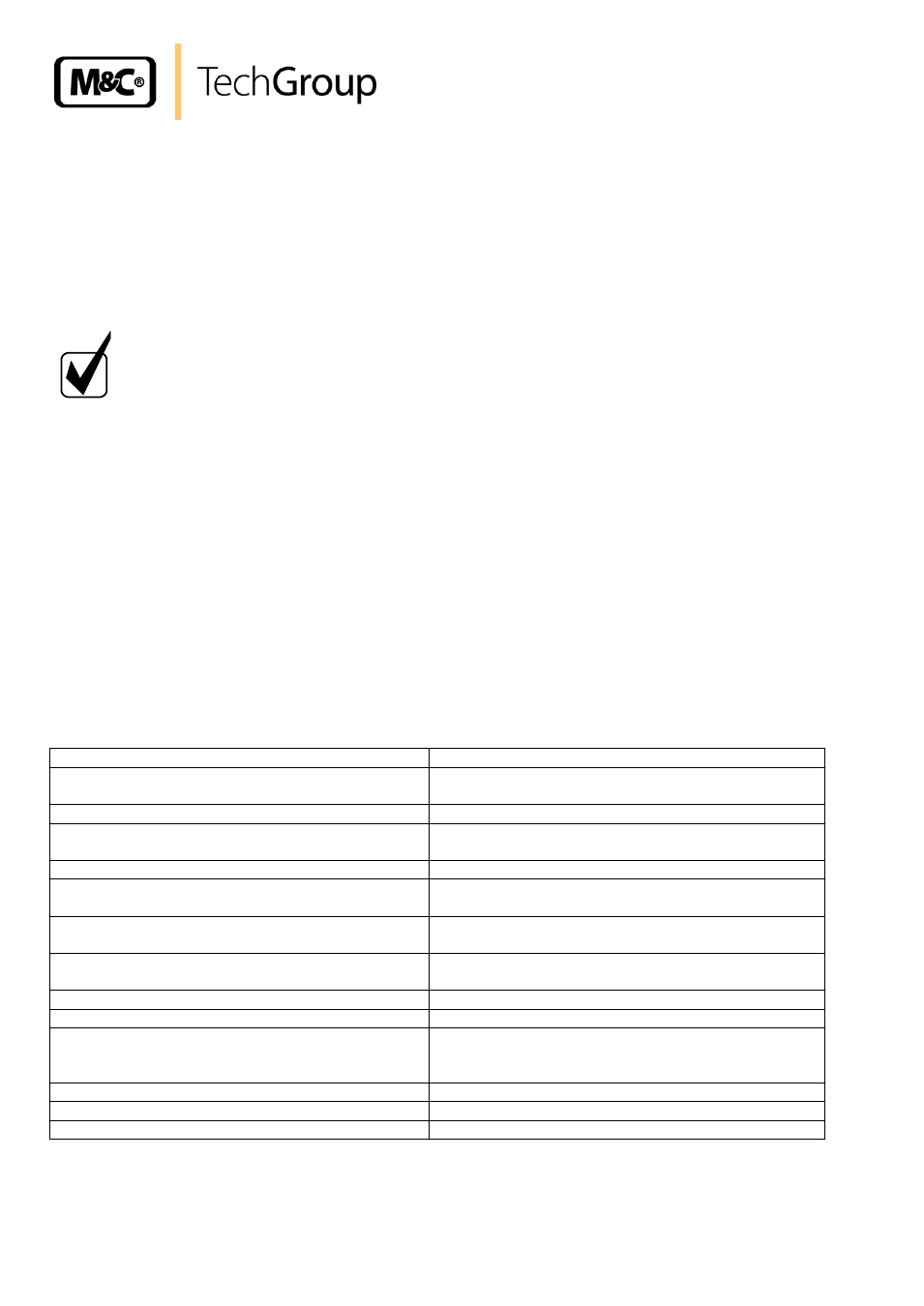

TECHNICAL DATA

Series SP

Version gas sample dilution probe SP2006-H/DIL ...

Insitu sample tubes and pre filters optional on

request

see leaflet 2-1.1a; 2-1.5.1; 2-1.6.1; 2-1.9.5

Dilution rates with the critical orifices ”a“ - ”g“

3)

a = 500 b = 200 c = 100 d = 50 e = 30* f = 20 g = 10 : 1

Sample flow rate depending on the critical ori-

fices ”a“ - ”g“

a = 1,4 b = 2,7 c = 5,5 d = 11 e = 19* f = 28 g = 55 l/hr

1)

Possibility to adapt the dilution factor

with dilution gas pressure-adjustment -5% to +30%

2)

Dillution gas flow rate with injector version I

or II

I: 480 - 600Nl/hr, optional for higher dilution rates

II: 1800-3000 Nl/hr

Dilution gas pressure on inlet of pressure con-

troller

min. 4,5 bar g, max. 16 bar g

Bypass injector /B: gas pressure-gas flow rate-

sample gas flow rate

at approx. 2 bar g - injector gas approx. 300 l/hr - sam-

ple gas approx. 150 l/hr

Process pressure

0,9 up to 2 bar abs.

Fault caused by process temperature variations

operation independent from process temperature

Fault caused by process low or over pressure

no fault as long as the differential pressure

ΔP at the di-

lution unit is >0,5 bar g and test gas is given to the

probe under process conditions

Fault caused by atmospheric pressure variations <1% with a variation of 50 mbar

Materials in contact with the sample gas

stainless steel 316Ti, quartz glass, FPM, graphite

Weight

approx. 30 kg

*Standard, others to be indicated along with order, intermediate values possible. 1) approx. at 3 bar dilution gas behind pressure controller.

2) -

5% not possible for orifice „g“. 3) with injector version I. Further technical data see leaflet SP2000, 2-1.1a.