Technical data – M&C TechGroup PSS-10_1 Operator's manual User Manual

Page 8

8

Gas sampling and gas conditioning technology

4-2.1.2-ME

8

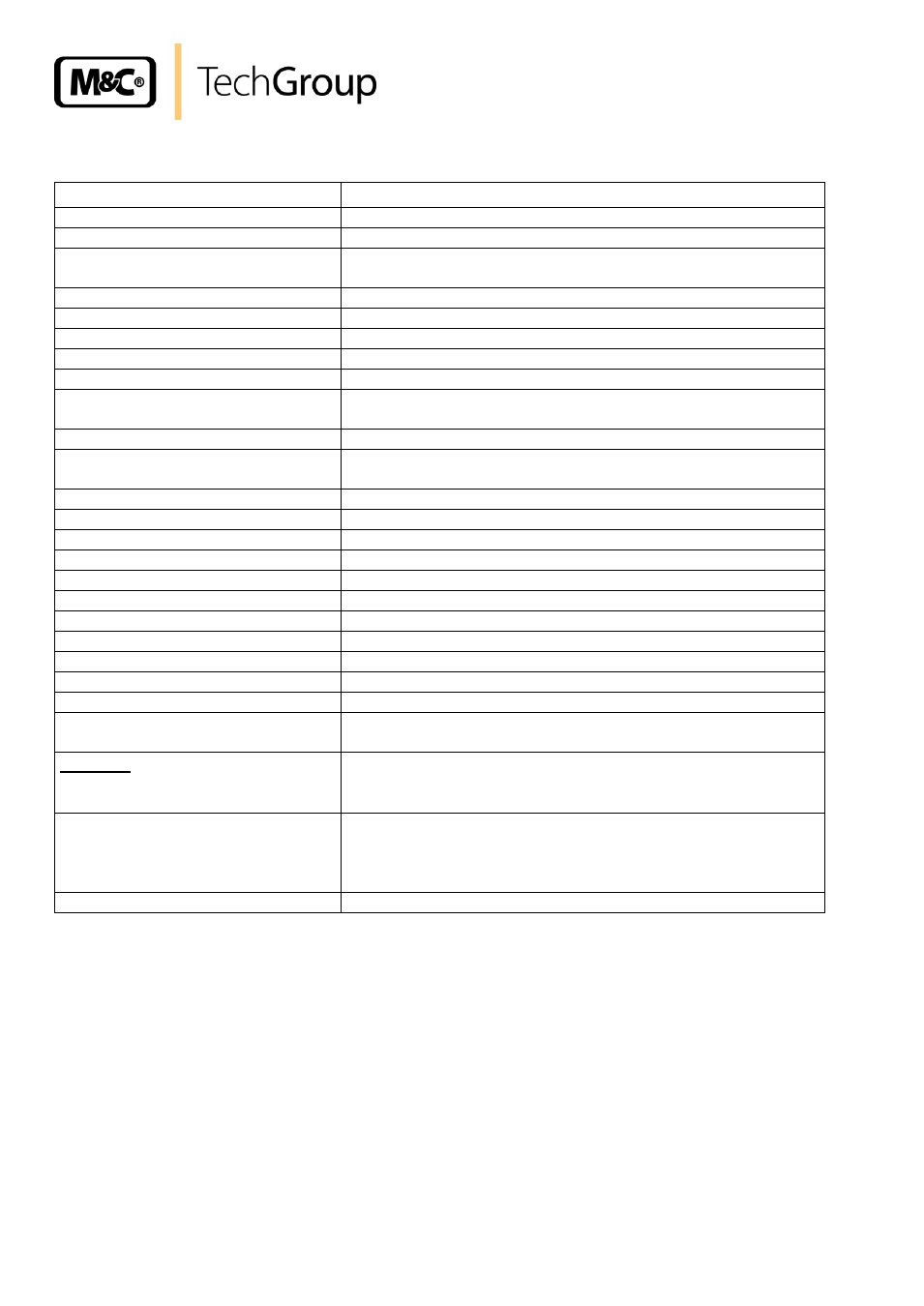

TECHNICAL DATA

Gas conditioning unit

Version PSS-10/1

Sample outlet dew point

range of adjustment: +2 °C … +15 °C, factory setting: +5 °C

Dew point stability

at const. conditions: < ±0,1°C

Sample inlet temperature

**max. 80°C

optional: **max.180°C with stainless steel bulkhead union

Sample inlet dew point

**max. +80°C

Gas flow rate

**max. 480 Nl/hr

Ambient temperature

**+5°C up to +40°C

Storage temperature

-25°C up to +65°C

Pressure

0,7 bar up to 1,4 bar abs.

Total cooling capacity at 25°C

ambient temperature

max. 80 kJ/hr

Number of gas inlets

1

Number of gas outlets

1

optional: max. 4

Medium connections

tube connection 4/6 mm

Material of sample contacting parts

stainless steel, glass, PVDF, VITON, Novopren

®

Ready for operation

approx. 10 min

Power supply

230V 50Hz ± 10% or 115V 60Hz ± 10%

Power consumption

max. 350VA

Fuse protection

6,3A t, 5x20mm with option temperature controller: 10A t

Electrical connection

Cold appliance plug with 2m of cable

Case protection

IP20

(EN 60529)

Housing

portable aluminium case

Housing dimensions (H x W x D)

555mm x 460mm x 290mm

Weight

approx. 24 kg

Part No. for 230V 50Hz version

Part No. for 115V 60Hz version

01G5000

01G5000a

Options:

Flow meter DK800R mounted in

sample gas outlet:

altern. 10-100 l/hr (Part No.: 01G9020), 25-250 l/hr (01G9021)

and 50-500 l/hr (01G9022) air

Temperature controller for heated

line:

Liquid alarm type

range of control: 0°C-200°C 230V, max. 4A

input PT100 115V, max. 4A

LA 1S/LA-1.4

Electrical equipment standard

EN 61010

PPH=Polypropylene, PTFE=Polytetrafluoroethylene (Teflon®), PVC=Polyvinyl chloride, PVDF=Polyvinylidenfluoride

* Standard

**

Maximum values in technical datas must be rated in consideration of total cooling capacity at 25 °C ambient temperature

and an outlet dew point of 5 °C.