M&C TechGroup SP3200 Operator's manual User Manual

Page 14

14

Gas sampling and gas conditioning technology

2-1.3.9-ME

Part No.

20S9045 + 20S9012

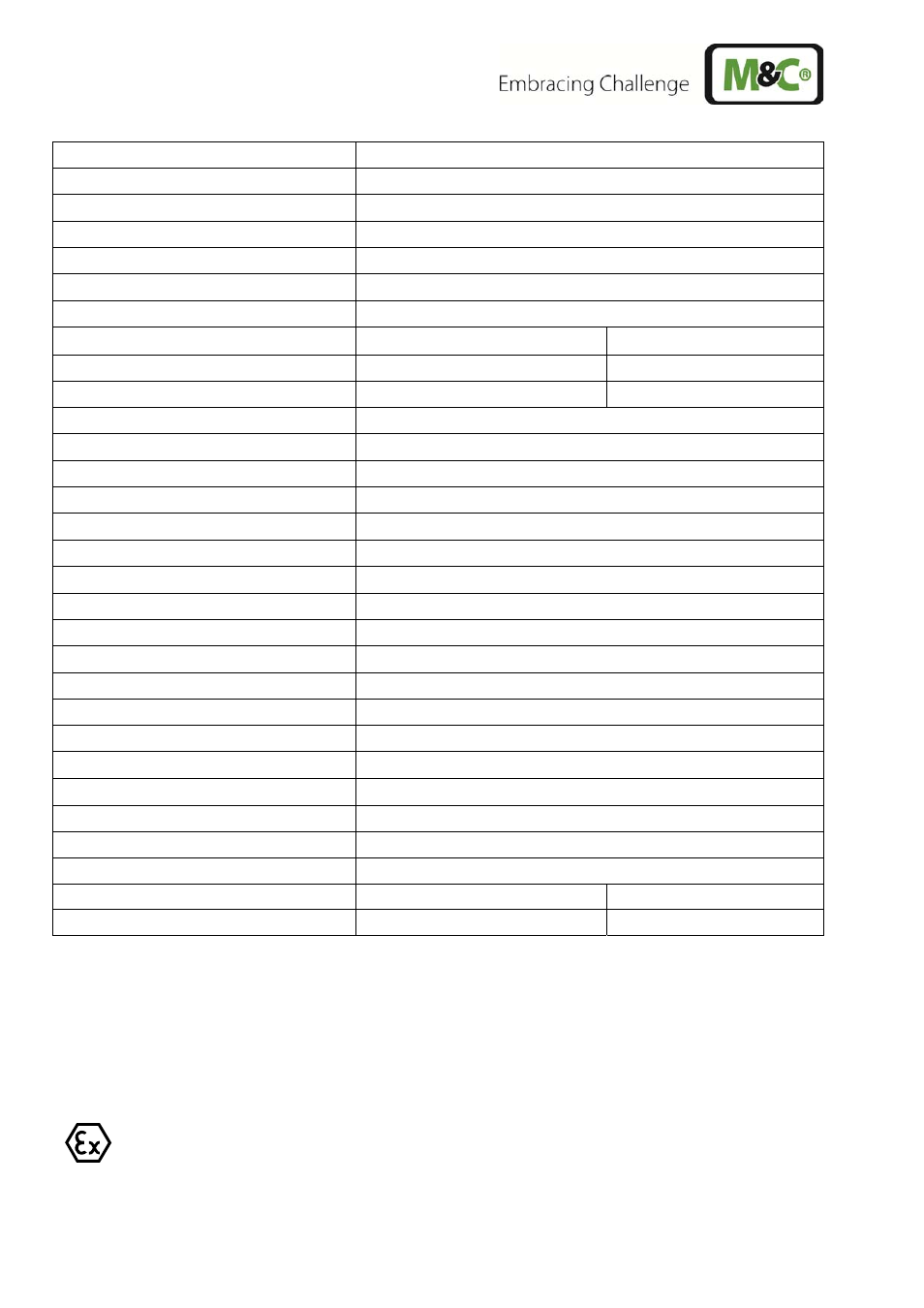

Way of test gas

/R/CC = via sample gas outlet or /R/CCF = via probe filter element

Check valve /R

check valve 1/4”

Opening pressure

>0,7 bar

Connection 6mm

tube

Maximum blow back pressure

6 bar abs.

Maximum operating temperature

+185 °C

Option high performance blow back valve

/BB

/BBF

Part No.

20S9008

20S9006

Way of blow back gas

via filter chamber

via probe filter element

Check valve

high performance check valve 3/8”

Opening pressure

>0,7 bar

Connection 8mm

tube

Maximum blow back pressure

6 bar abs.

Maximum operating temperature

185 °C

Option test gas valve / shut-off valve

/C + /I

Part No.

20S9011 + 20S9009

Way of test gas

via sample gas outlet with shut-off to the process

Check valve

check valve 1/4”

Opening pessure

>0,7 bar

Connection

6mm tube

Shut-off valve

bellow-type valve with pneumatic drive

Pressure control air

3-10 bar

Connection control air

1/8” NPT i

Option second sample gas outlet

/2X

Part No.

20S9015

Connection

1/4” NPT i

Option spun glass cartridge

/FW

Part No.

20S9047

20S9046

Material

SS316Ti, Novapress

SS316Ti, Graphite

Maximum surface temperature of the gas sample probe:

The maximum surface temperature of the gas sample probe depends on the temperature of the

process medium and the options used (heating HEX5-x.08 and backflush /RS). Under no cir-

cumstances, the sample probes SP3200(V)… must exceed the maximum surface temperature

fixed by the temperature class.

The maximum surface temperatures and inferable temperature classes of the gases are shown

in the following table.