Linear error compensation – ACU-RITE VRO 300T User Manual

Page 43

Setup

VRO 300T

36

Linear Error Compensation

The

VRO 300T

includes a linear error compensation feature that enables you

to compensate for machine tool inaccuracies. You can have up to 99 different

compensation segments per encoder.

In order for linear error compensation to function properly, the readout needs

to be able to establish the segment boundaries in the same physical locations

each time you turn on the readout. This means that you must find the

encoder’s reference mark. Refer to page 6, “Power-On Position Recovery”.

To begin the process, select

ERROR COMPENSATION

from the

JOB SETUP

list.

Error compensation is applied to each encoder individually, so you must first

select the axis that you want to work with. You may use a display axis key

(

X

for example) to select the encoder, unless the encoder is coupled with

another one, or the encoder is displayed as the U or V axis. If that is the case,

enter the number of the input that the encoder is connected to.

Once you have selected the encoder, the readout displays the error

compensation table for that encoder. Initially, there is only one segment

defined, and it applies from one end of the encoder to the other.

The following softkeys let you begin defining the table.

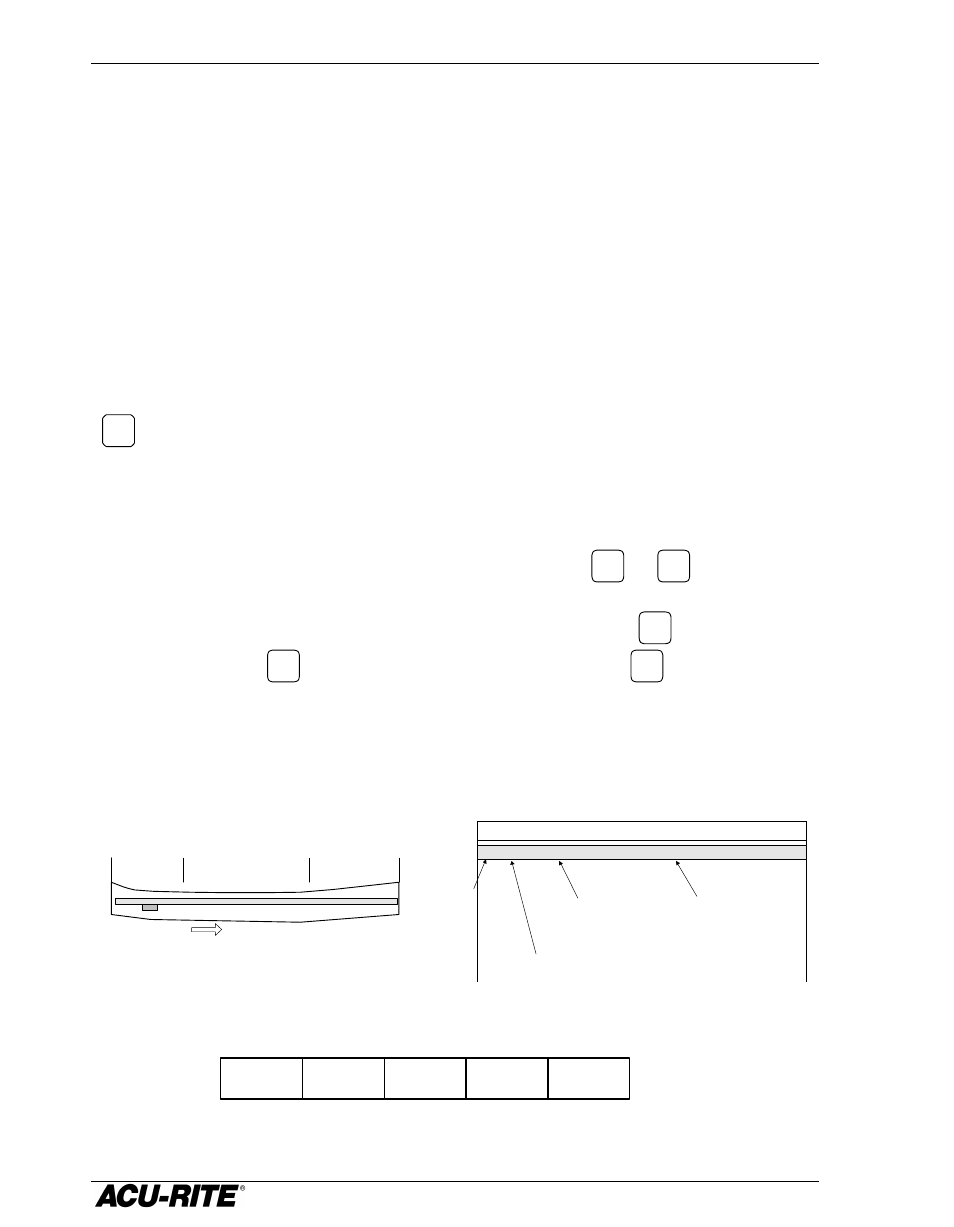

Segment 2

Segment 1

Segment 3

Machine bed side view

(slightly exaggerated)

+ Count Direction

Examples:

•

X axis displays encoder 1; you may press

X

or

1

to select this encoder.

•

Z1 axis displays encoders 2 + 3; you may press

Z1

or

2

to select encoder 2, but you must press

3

to

select encoder 3.

01 0 PPM ENCODER END - ENCODER END

ENCODER 1 ERROR COMPENSATION

Segment

number

Compensation

factor in parts

per million

Most negative

segment boundary

Most positive

segment boundary

ENTER

COMP

CALCULATE

COMP

ANCHOR

SEGMENT 1

DONE