Filters, Condensate drain, Condensate drain piping – York ECO2 YPAL 050 User Manual

Page 32: Condensate drain trap

32

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

Installation

FILTERS

Two-inch “throwaway” filters are standard and factory

installed in a filter rack located prior to the evaporator

coil. Any optional pre-filters ordered with the unit will

be shipped inside the unit, but must be field installed.

The unit can also be ordered with an extended cabinet

and 95% efficient post-filters. These post-filters are

installed at the factory.

Pre-filters must always be installed ahead of the

evaporator coil. Post and pre-filters must be kept clean

and replaced with the same size and type as shipped with

the unit. Dirty filters will reduce the capacity of the unit

and may result in frosted coils and safety shutdowns.

Required filter sizes and quantities are shown in Table

2-6. The unit should never be operated for any length

of time without the proper filters installed in the unit.

CONDENSATE DRAIN

Condensate Drain Piping

The eco

2

cooling coils are located in the units so that

the supply air is drawn through them. This results in

the condensate being subjected to negative (-) static

pressure. Unless some means of pressure equalization is

provided in the condensate drains, the air rushing back

through the drainpipe will cause the condensate to build

up in the base rails. As the unit continues to operate, the

accumulated water will be carried with the air stream,

overfilling the base rails causing possible water leaks

into the supply duct and/or causing water damage in

the building. A trap must be installed to prevent this

condensate water build-up (see Figures 2-6 & 2-7).

Under high latent load conditions condensate may

form in the base and side rails of the unit. The unit is

designed to contain this moisture and prevent it from

leaking into the conditioned space. In order to dispose

of this condensate, two condensate drain connections

are located on the side rails on each side of the unit

and in the base rail on the return end of the unit. There

are five (5) condensate drains on the unit. Since these

connections are also under negative pressure, they must

be trapped using the same design criteria as the main

drain pan.

Condensate Drain Trap

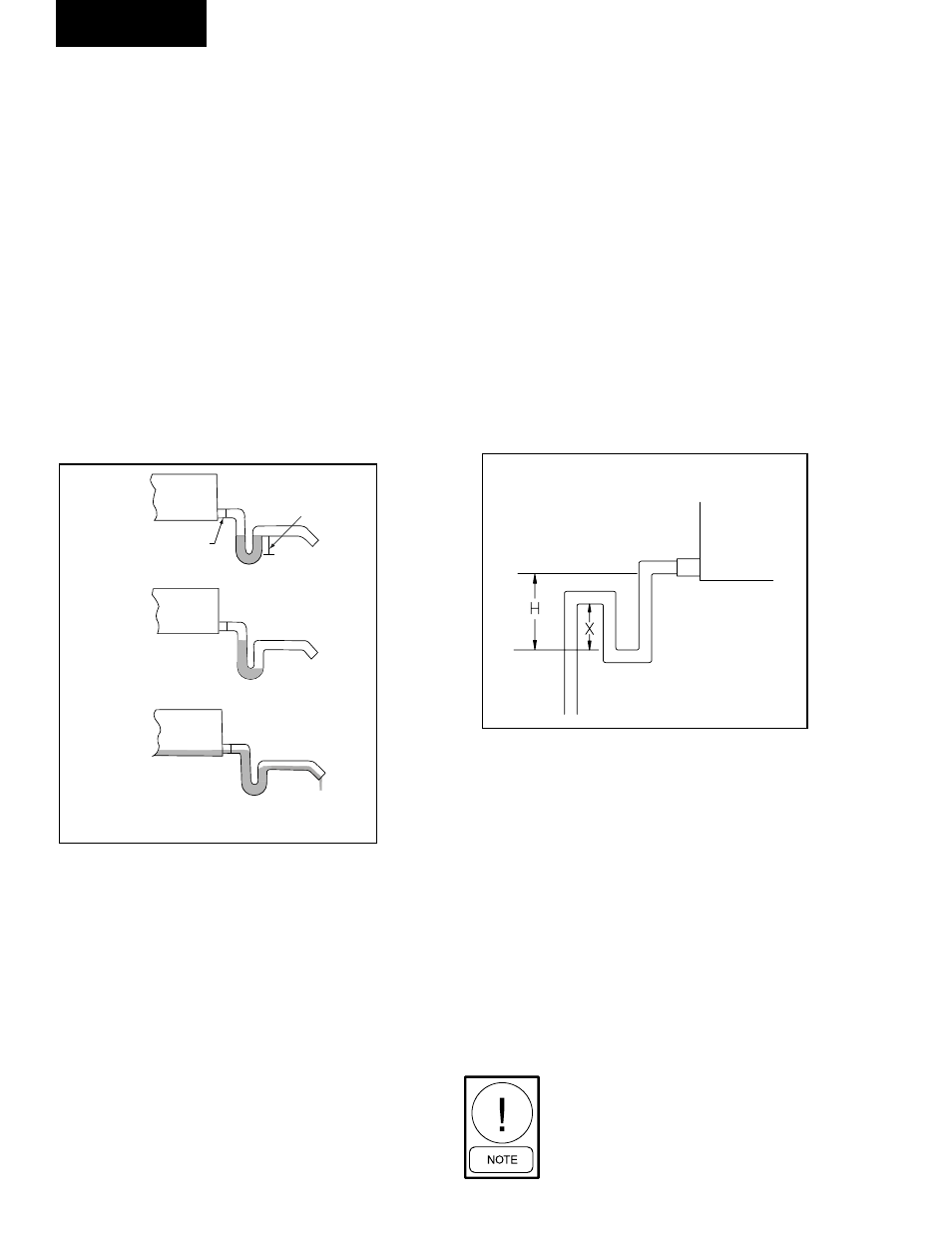

For “Draw-through” applications install a trapped

condensate drain line at unit drain connection (see

Figure 2-7 according to all governing codes. “H”

dimension must be at least 1 inch greater than design

Total Static Pressure (TSP) of fan.

The trap and drain lines should be protected from

freezing. Plumbing must conform to local codes. Use

a sealing compound on male pipe threads. Install

condensate drain lines from the 1-1/4 inch NPT female

connections on the unit to an open drain.

The unit must be properly trapped and

charged with water before the units

are started.

FIG. 2-6

–

DRAIN TRAP SHOWING WATER

LOCATION DURING DRAW THROUGH

OPERATION STAGES

BASE

RAILS

BASE

RAILS

BASE

RAILS

DRAIN

NIPPLE

TRAP

NO.1 - FAN OFF

NO. 2 - TRAP CONDITION WHEN FAN STARTS

NO. 3 - FAN RUNNING AND CONDENSATE

COOLING COIL

DRAIN PAN

FIG. 2-7

–

TRAP DETAIL FOR DRAW THROUGH

APPLICATION

"H" must be at least

1 inch plus fan total

static pressure

"X" = 1/2 "H"

LD05370-1

LD13269