Sharp SF-1120 User Manual

Page 89

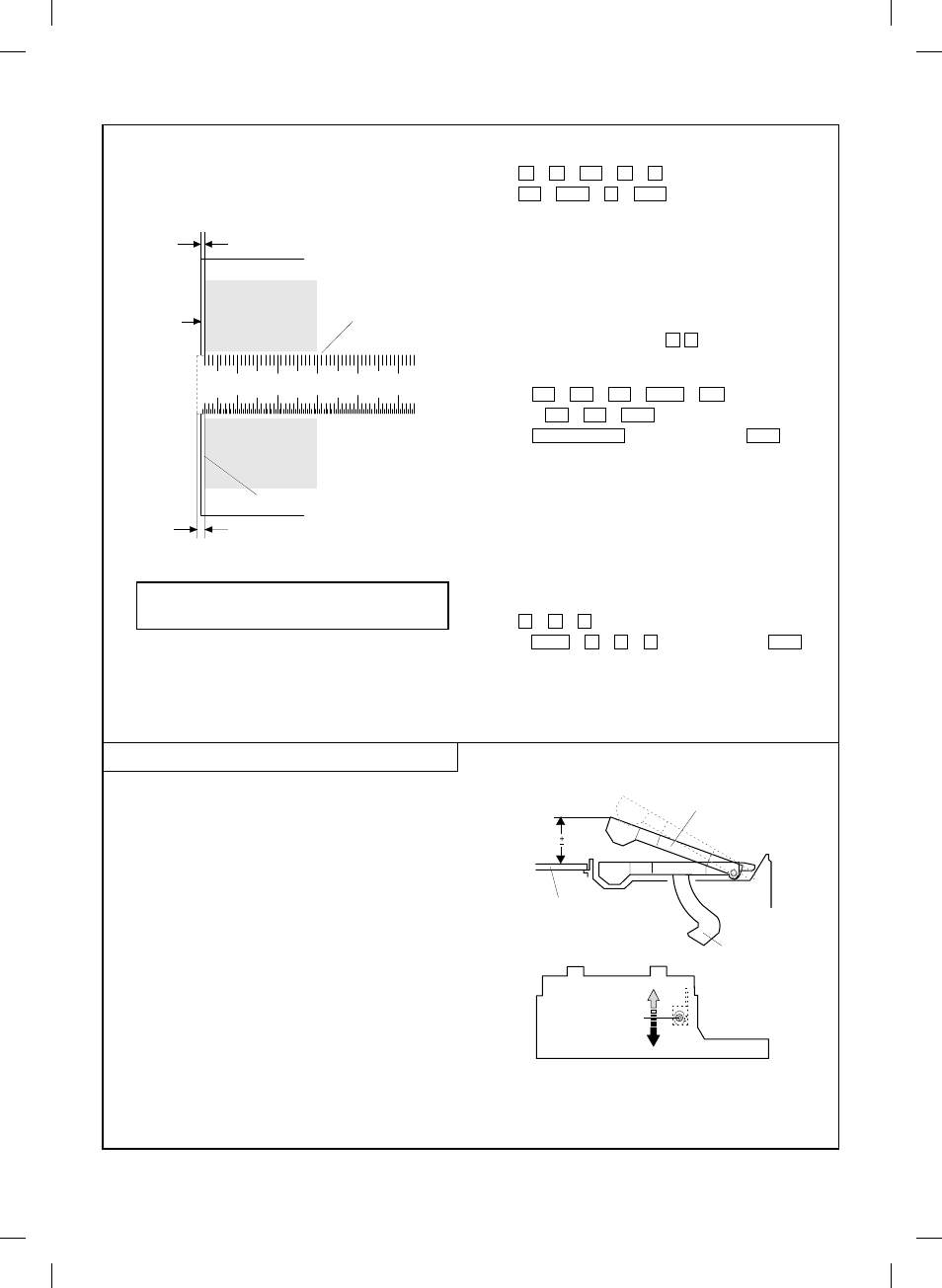

(11) Make a normal copy and check that the image loss and the

void amount are within the specified range.

(Specified range)

•

Image loss: 0

∼

4mm

•

Void amount: 1

∼

3mm

(12) Press the clear key and cancel simulation 50-01.

Note: When the RRC-A and RRC-B values are changed

in simulation 50-01, be sure to adjust the copy lead

edge void area.

When adjustment is made with simulation 50-02:

50-01. In simulation 50-02, L1 and L2 values can be direct-

ly set. It is easy and simple. The void area adjustment is

also the same as simulation 50-01.

[Adjustment procedure]

(1)

Put a scale on the original table.

(2)

C

→

P

→

0/

◊

→

P

→

5

→

0/

◊

→

PSW

→

2

→

PSW

With the above key operation, simulation50-02 is performed

and the machine starts warming up.

(3)

The lower two digits of L1 value is displayed on the copy

quantity display. The top digit is for data identification.

•

L1 : Lead edge shift at 200% (

|||

mm, 3 digits)

•

L2 : Lead edge shift at 100% (

✕✕✕

mm, 3 digits)

Example of display

•

For 42.5mm, the display is 2 5 .

(4)

Use the % key and the 10 digit key pad to set A and b values

to zero. Make copies at 100% and 200%.

•

0/

◊

→

0/

◊

→

0/

◊

→

% key

→

0/

◊

→

0/

◊

→

0/

◊

→

PSW (A copy at 100% is made.)

•

Enlargement key

→

(Lens shift, ready)

→

PSW (A

copy

at 200% is made.)

(5)

Measure the distance between the copy paper lead edge and

the copy image lead edge in each copy. Enter L1 and L2

values with the zoom key and the 10 digit key pad. With this

operation, RRC-A and RRC-B values in simulation 50-01 are

automatically calculated and stored.

Input procedure

(Example)

When L1 = 24.5 mm and L2 = 15.0mm:

Check that the lowest digit of the magnification ratio display is

"A," and perform the following key operation.

2

→

4

→

5 ("45" is displayed on the copy quantity display.)

→

% key

→

1

→

5

→

0 ("50" is displayed.)

→

PSW

(6)

After this, check shift and image loss, and void amount in each

copy similarly to simulation 50-01.

2-4. Original detecting section

A. Original detecting arm unit adjustment

1

OC switch ON timing adjustment

Execute simulation 40-01. (C

→

P

→

0

→

P

→

4

→

PSW

→

1

→

PSW)

•

Slowly tilt down the original detecting arm unit and loosen the

original cover switch actuator adjustment screw so that the

auto paper selection display lamp turns off when the height

from the table glass to the arm unit top is 36.5

±

0.5mm. Then

slide the actuator to adjust. (If the original cover ON timing is

shifted, the original detecting function may malfunction.)

10

20

30

40

50

Void area

0~3mm

Paper end

Scale image

Solid edge

Image loss

0~4mm

Full-size(100%) copy

36.5 0.5

Original detecting arm unit

Glass

Original cover switch actuator

Actuator

adjustment

screw

7 – 15