6) process control function – Sharp SF-1120 User Manual

Page 43

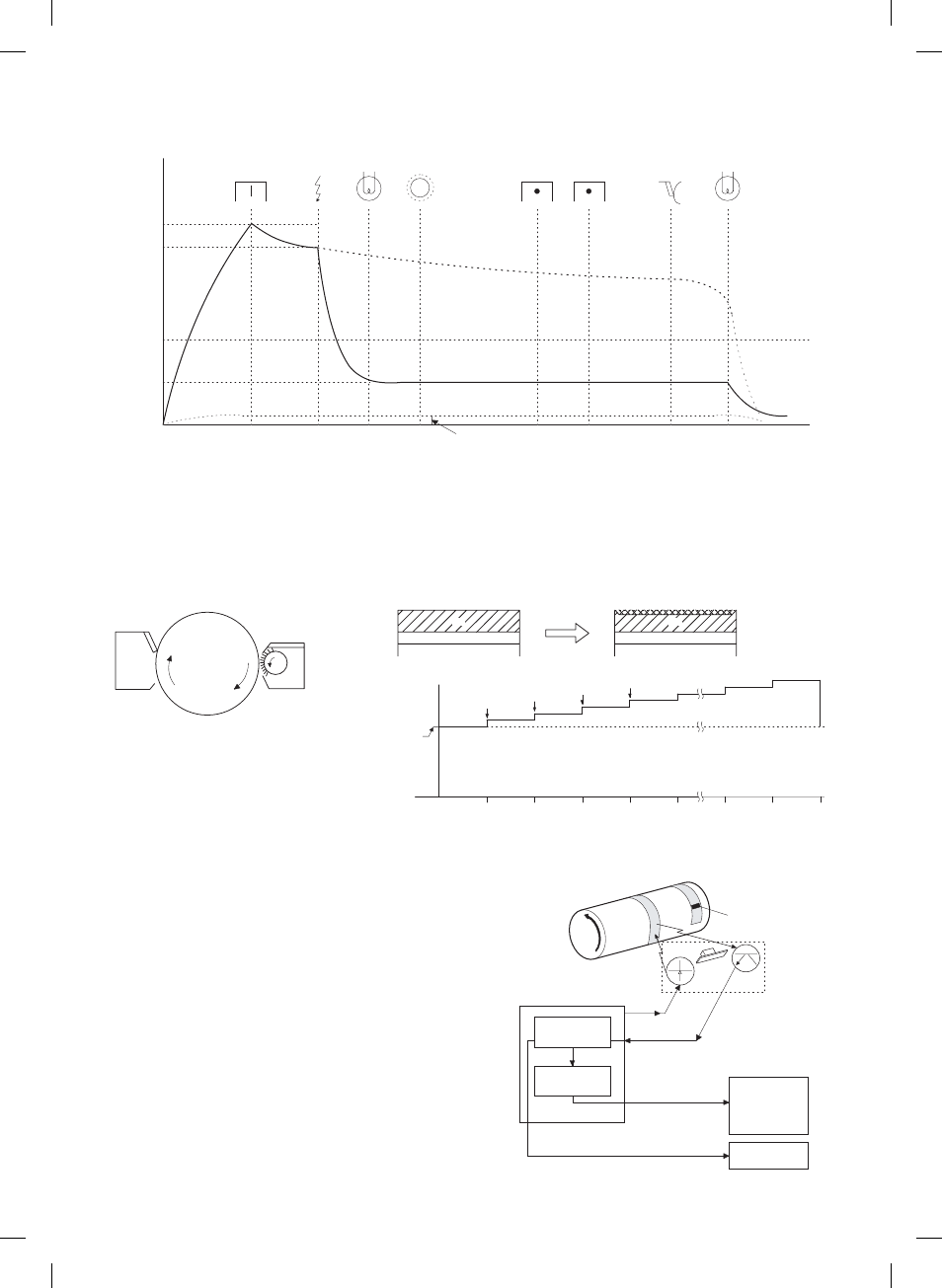

(4) Transition of photoconductor surface potential

(5) Photoconductor drum sensitivity correction

In this model, fall in sensitivity due to long use of the photoconductor

drum is corrected by the copy lamp light intensity to prevent against

considerable change in copy quality.

The photoconductor drum sensitivity fall correction is performed as

follows:

(6) Process control function

[Summary]

The process control function detects the density of the standard toner

image formed on the photoconductor, the density of the initial image

and controls the charging grid voltage so that the same level as the

initial image density is provided.

That is, the process conditions are established and the high voltage

output and exposure level are controlled to stabilize the toner density.

In this model, the density sensing level is automatically set.

D L

BL

Charge

Exposure

Develop

Transfer

Separate

Clean

Dark area

Developing bias voltage

Light area

Residual potential

-730V

-215V

Cleaner

OPC drum

Develop

CTL

CGL

CTL

CGL

Sim46

CLV

0

1step = 0.33

(Sim46)

(NEW)

(USED)

Time (min)

R

F

MAin control PWB

High voltage PWB

(Light quantity

correction)

CPU density

judgement

I/O MC grid

output selection

MC grid bias

output (density

correction)

in each mode

Mark

5 – 14