Sharp SF-1120 User Manual

Page 36

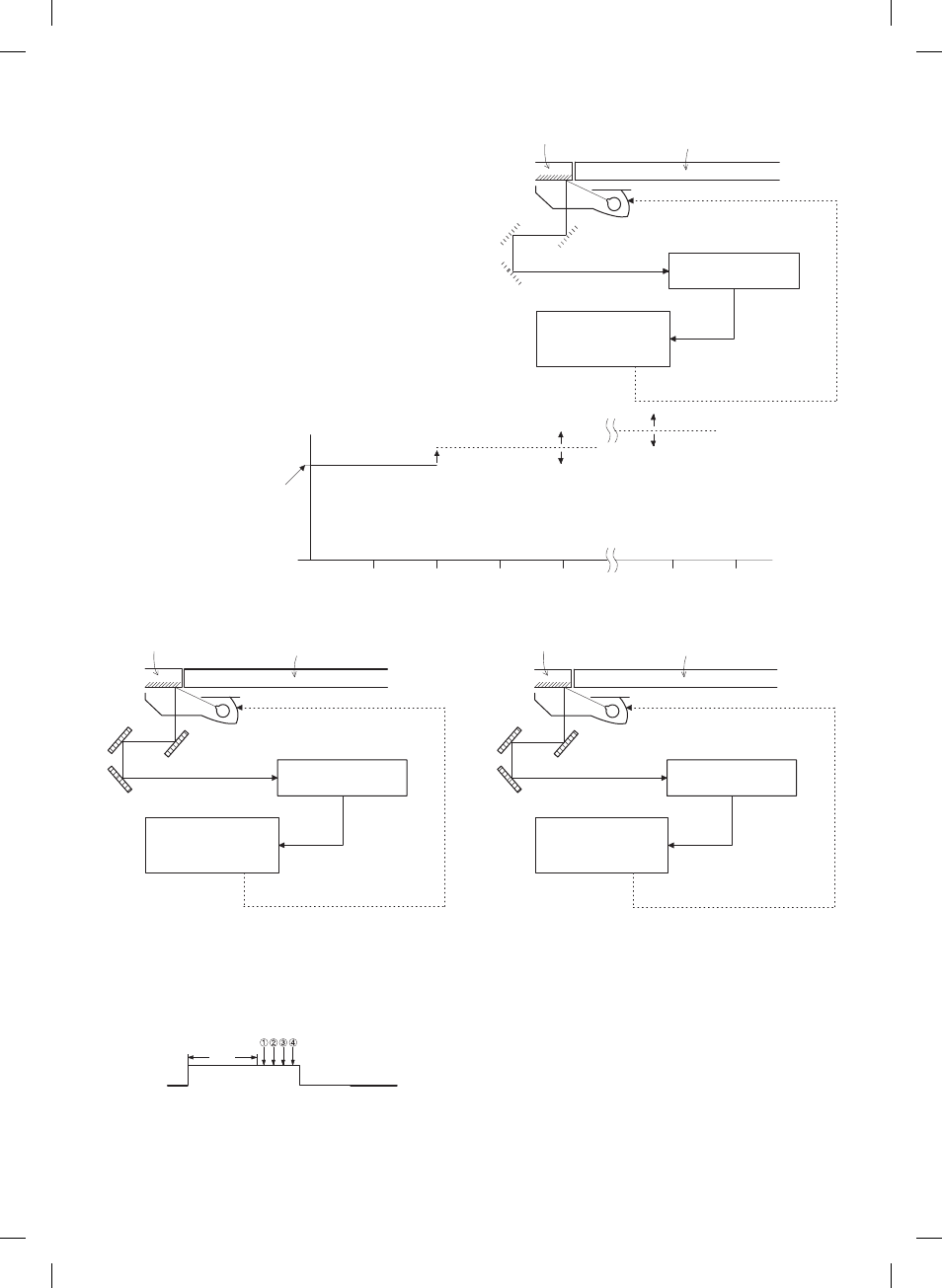

(Optical system dirt correction)

This model perform dirt correction by changing the copy lamp inten-

sity according to the dirt degree in the optical system (the copy lamp

unit, No. 1 mirror, No.2 mirror, No.3 mirror) to prevent against remark-

able degrading of copy quality.

The reference value is the AE sensor output value which is obtained

when the reference plate is exposed with the copy lamp voltage of

67.0V (134.0V) at power ON.

This value is checked with sim 44-08, 09.

(1) Setting the reference value for optical system correction.

1

Clean the optical system at every maintenance.

2

Perform Simulation 46-1.

(The previous data are cleared.)

3

After completion of Simulation 46-1, when performing the first

mirror initialization, measure light quantity of the copy lamp.

Obtain the average value from the four measurement values and

use the average value as the reference value for correction.

Obtain the average value of four AE sensor values, and store it.

(2) Dirt correction

1

Measure light quantity when performing mirror initialization.

2

Store the correction data into memory.

3

Reset the register inside the CPU.

Reference plate (Glass holder)

Table glass

Copy lamp light quantity "UP"

Automatic exposure

sensor

CPU

Reference value

>Measured value

Correction data output

100

200

300

400

79.8K

80K

CLV + (0.7)

Sim46

CLV

CL(V) = INI CL(V) + (0.33 x 2)

1step = (0.33 x 2)

Reference plate (Glass holder)

Table glass

Automatic exposure

sensor

CPU reference value

setting

CL

800ms

Light quantity

measurement

Copy lamp light quantity "UP"

CPU

Reference value

>Measured value

Correction data output

Reference plate (Glass holder)

Table glass

Automatic exposure

sensor

5 – 7