Sharp SF-1120 User Manual

Page 31

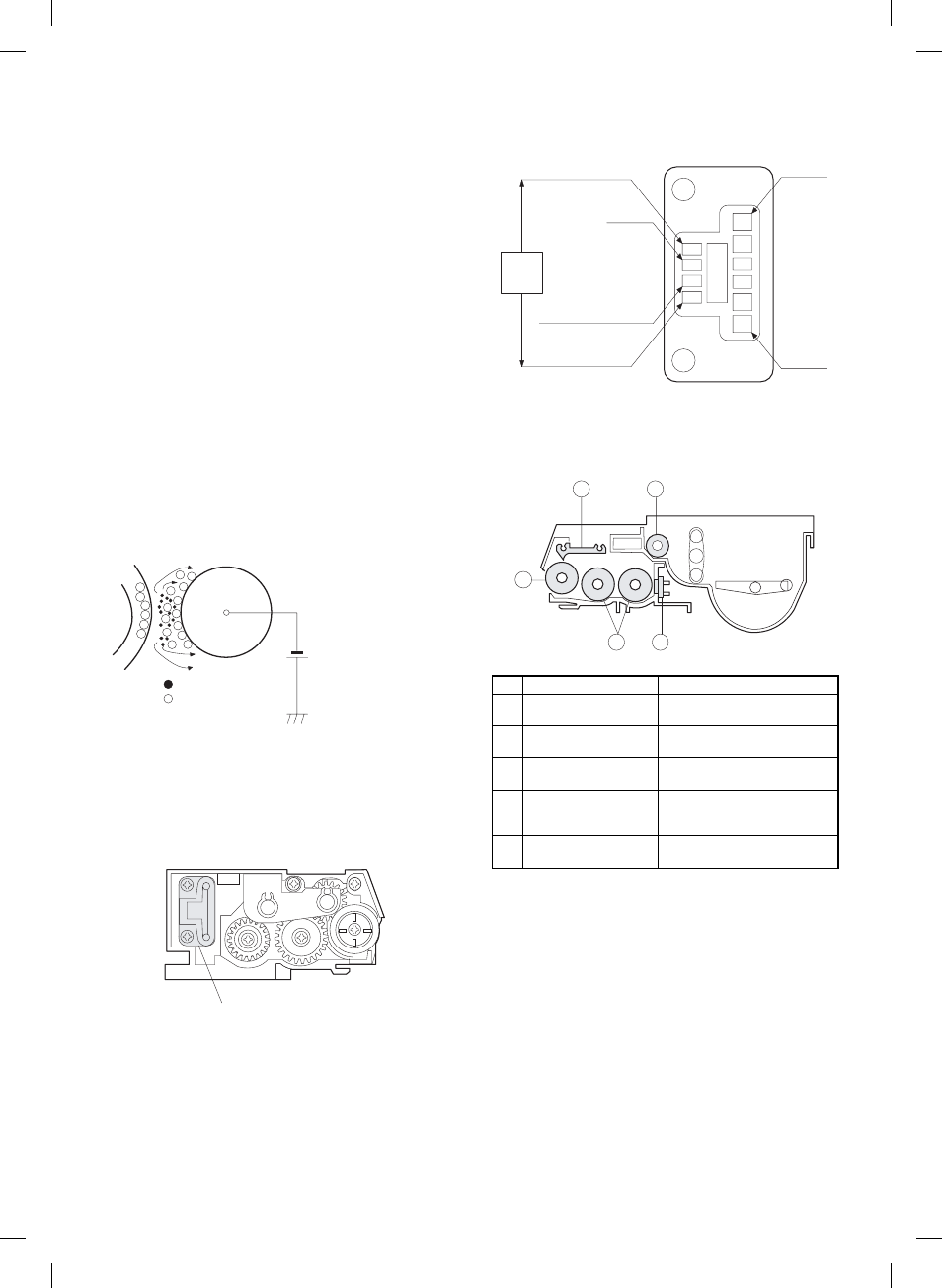

2. Developing section

1) General descriptions

(1) Two-component developer

The developer is composed of toner and carrier.

Carrier serves as a medium for attaching toner onto the electrostatic

image on the photoconductor drum.

By stirring toner and carrier, they are rubbed to be charged positive

(+) and negative (–) respectively.

Since developer will deteriorate to degrade copy quality, it should be

replaced regularly.

(2) Two-component magnetic brush development

The rotatable non-magnetic sleeve is provided over the magnet roller

and is rotated.

Carrier forms a magnetic brush on the sleeve surface by magnetic

force to attach toner onto the electrostatic image on the photoconduc-

tor drum.

(3) Developing bias

When the photoconductor is charged and exposed to light (ex-

posure), the surface potential (voltage) of the photoconductor will not

be lost completely. (The residual potential remains.)

Toner is attracted to the photoconductor by this residual potential,

dirtying the photoconductor. As a result, a dirty copy of white back-

ground is generated.

To prevent against this, a voltage of the same polarity and higher than

the residual potential is applied to the MG roller, preventing toner from

being attached to the photoconductor surface.

(4) DV harness

The toner density sensor, the developing bias, and the developing

unit identification resistance harness.

(For details, refer to [6] DISASSEMBLY AND ASSEMBLY.)

2) Basic composition

No.

Name

1

Magnet roller

Forms a magnetic brush of carrier

by magnetic force.

2

Developing doctor blade

Limits the height of the magnetic

brush.

3

Developing MIX roller

Stirs carrier in the developing unit

and distributes toner evenly.

4

Toner

transport

roller

Transport toner sent from the

toner hopper unit to the stirring

section.

5

Toner

density

sensor

Senses toner density in

developer.

MG roller

Residual potential < DV BIAS

Toner

Carrier

DV BIAS

-200V

Developing bias voltage

(Viewed from the rear of develoing unit)

DV harness connector

(Details of DV harness connector)

*Resistance value is identified by color

For color identification

GND

GND

*For toner density sensor

Resistor

For bias

VB

1

2

4

3

5

5 – 2