Controller structures – Siemens MICROMASTER 440 User Manual

Page 64

6 Commissioning

Issue 10/06

MICROMASTER 440

64

Operating Instructions (Compact)

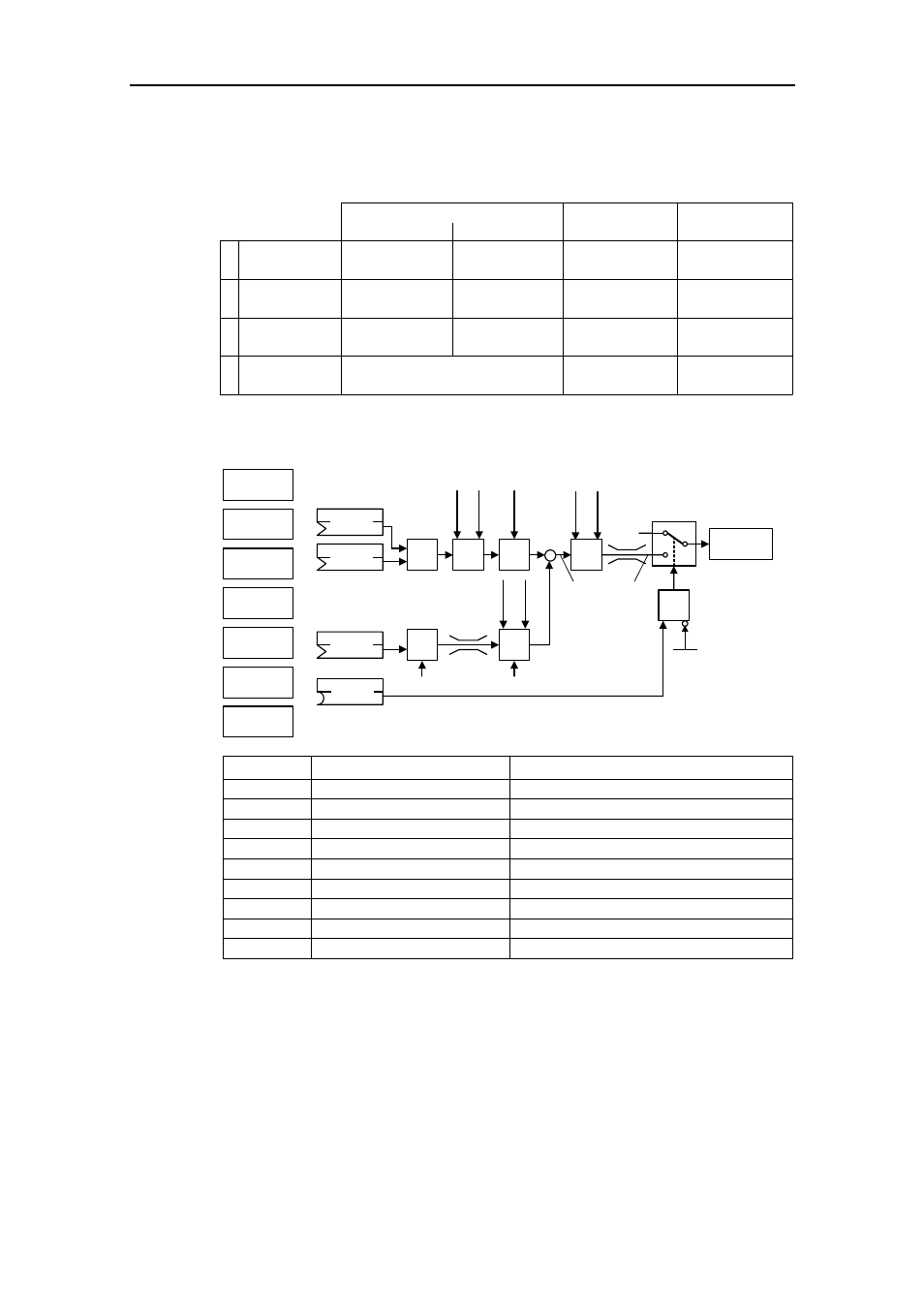

Controller structures

These structures are selected using parameters P2200 and P2251.

P2200 = 0:0

2)

P2251 = 0

1

P2200 = 1:0

2)

P2251 = 0

2

P2200 = 0:0

1)

P2251 = 1

3

P2200 = 1:0

1)

P2251 = 1

4

−

−

−

ON: active

OFF1/3: active

ON: -

OFF1/3: -

ON: -

OFF1/3: -

SUM

PID controller

RFG

PID-RFG

1) will take change with drive running

2) change only taken when drive stopped

VSD *

Dancer control

ON: active

OFF1/3: active

ON: active

OFF1/3: active

ON: active

OFF1/3: active

ON: active

OFF1/3: -

ON: -

OFF1/3: active

Setpoint via

PID control

VSD *

* Variable speed drive (VSD)

PID control

PID

MOP

ADC

PID

SUM

PID

PID

FF

USS

BOP link

USS

COM link

CB

COM link

ADC2

P2254

P2253

PID

RFG

PID

PT1

−∆

PID

P2200

P2264

PID

PT1

PID

SCL

&

P2251

Output

PID

0

1

Motor

control

P2

25

7

P2

25

8

P2

26

1

P2271

P

226

9

P

227

0

P2265

P2

28

0

P2

28

5

0

Parameter Parameter

text

Example

P2200

BI: Enable PID controller

P2200 = 1.0

PID controller active

P2253

CI: PID setpoint

P2253 = 2224 PID-FF1

P2264

CI: PID feedback

P2264 = 755 ADC

P2267

Max. PID feedback

P2267

Adapt to the application

P2268

Min. PID feedback

P2268

Adapt to the application

P2280

PID proportional gain

P2280

Determined by optimizing

P2285

PID integral time

P2285

Determined by optimizing

P2291

PID output upper limit

P2291

Adapt to the application

P2292

PID output lower limit

P2292

Adapt to the application