13 inverter protection, 14 motor protection – Siemens MICROMASTER 440 User Manual

Page 45

Issue 10/06

6 Commissioning

MICROMASTER 440

Operating Instructions (Compact)

45

6.4.13 Inverter

protection

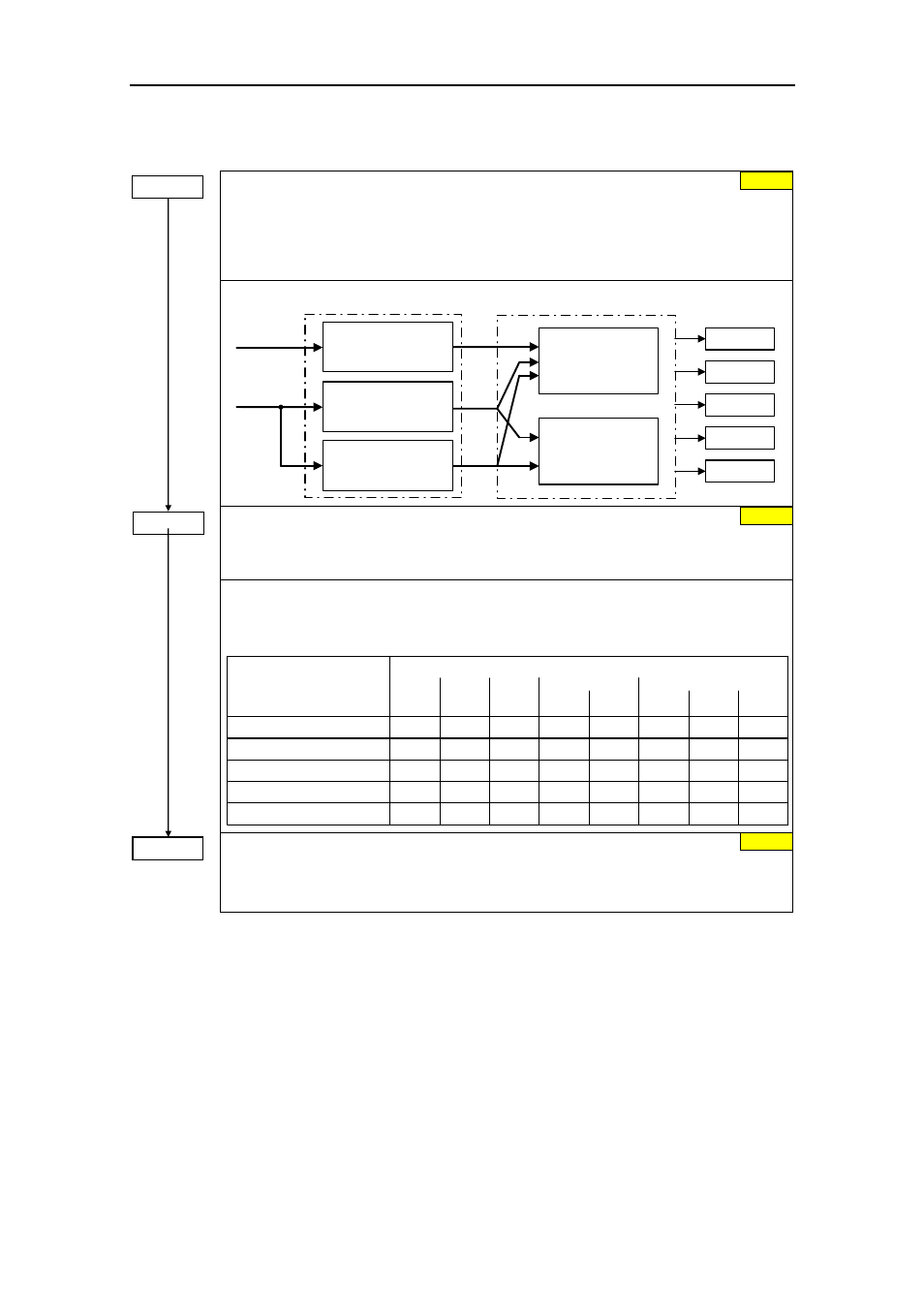

Inverter overload reaction

Selects reaction of inverter to an internal over-temperature.

0 Reduce output frequency

1 Trip (F0004 / F0005)

2 Reduce pulse frequency and output frequency

3 Reduce pulse frequency then trip (F0004)

A0504

A0505

A0506

F0004

F0005

Inverter overload reaction

P0290

f_pulse

control

i_max control

(U/f)

Current control

(SLVC, VC)

r0036

r0037

Heat sink

temperature

P0292

IGBT

temperature

P0292

i

2

t

P0294

Inverter monitoring

P0292 =...

Inverter temperature warning

Defines the temperature difference (in ºC) between the Overtemperature trip threshold and

the warning threshold of the inverter. The trip threshold is stored internally by the inverter

and cannot be changed by the user.

Temperature

MM440, Frame Size

110 °C

140 °C

95 °C

145 °C

A - C

D - F

Input rectifier

-

Cooling air

-

Control board

-

80 °C

145 °C

F

600 V

-

-

-

-

-

-

88 °C

150 °C

FX

95 kW

CT

91 °C

150 °C

110 kW

CT

75 °C

55 °C

75 °C

55 °C

65 °C

65 °C

80 °C

145 °C

GX

132 kW

CT

82 °C

147 °C

160 kW

CT

75 °C

55 °C

75 °C

55 °C

65 °C

65 °C

88 °C

150 °C

200 kW

CT

75 °C

50 °C

65 °C

IGBT

Heat sink

trip

T

= T

- P0292

Temperature warning threshold of inverter T_warn

Temperature shutdown threshold of inverter T_trip

warn

Delay, fan shutdown

This defines the delay time in seconds between powering down the frequency inverter and

then powering-down the fan. A setting of 0 means that the fan is immediately shut down

(powered-down).

6.4.14 Motor

protection

In addition to the thermal motor protection, the motor temperature is also included

in the adaptation of the motor equivalent circuit diagram data. Especially for a high

thermal motor load, this adaptation has a significant influence on the degree of

stability of the closed-loop vector control. For MM440 the motor temperature can

only be measured using a KTY84 sensor. For the parameter setting P0601 = 0,1,

the motor temperature is calculated / estimated using the thermal motor model.

If the frequency inverter is permanently supplied with an external 24V voltage, then

the motor temperature is also tracked/corrected using the motor temperature time

constant – even when the line supply voltage is switched-out.

0 s

P0295 = ...

P0290 = ...

0

15 °C