9 reporting a problem, 10 corrective actions, 11 recommended test equipment – Emerson Series 600T User Manual

Page 89: Table 13 recommended test equipment and tools, 12 limited life components, Reporting a problem, Corrective actions, Recommended test equipment, Limited life components, Table 13

Maintenance

77

7.9

Reporting a Problem

If a problem occurs within the Liebert FS, review all alarm messages along with other pertinent data.

This information should be given by telephone to the Liebert service representative’s office nearest

you. This information can be downloaded to Liebert Global Services by using the optional modem.

Contact Liebert Global Services at 1-800-LIEBERT to report a problem or to request assistance.

7.10 Corrective Actions

For each alarm message on the operator control panel, you can find the recommended corrective

7.11 Recommended Test Equipment

Table 13 lists recommended test equipment and tools required to maintain, troubleshoot and repair

the Liebert FS. You may substitute instruments of equivalent range and accuracy.

All instruments should be calibrated and be within the current calibration cycle. Calibration data for

the instruments should be maintained in equipment-history files and the instruments labeled for

audit and verification.

7.12 Limited Life Components

Your Liebert FS has a design life well in excess of 15 years. Well-maintained units can continue to

provide economic benefits for 20 years or more. Long-life components are used in your Liebert FS

wherever practical and cost-effective.

However, due to current component material and manufacturing technology limitations, a few compo-

nents in your Liebert FS will wear out and require replacement in less than 10 years. The following

limited-life components are utilized in your Liebert FS. In order to prevent a wear-out failure of one of

these components affecting your critical load operations, it is recommended these components be peri-

odically inspected and replaced before their expected wear-out life. Individual users may have site-

specific requirements that differ from these typical life expectations.

Power capacitors are considered “failed” when their measured capacitance is –5% below their name-

plate rating.

In most cases, replacement components must exactly match the original component specifications and

are not readily available from third-party component distributors. For assistance with your specific

component specifications, replacement component selection and sourcing, call 1-800-Liebert.

For customers using Liebert Global Services’ Preventive Maintenance Services, periodic inspection of

these components are part of this service as is recommending to customers replacement intervals to

avoid interruptions in critical load operations.

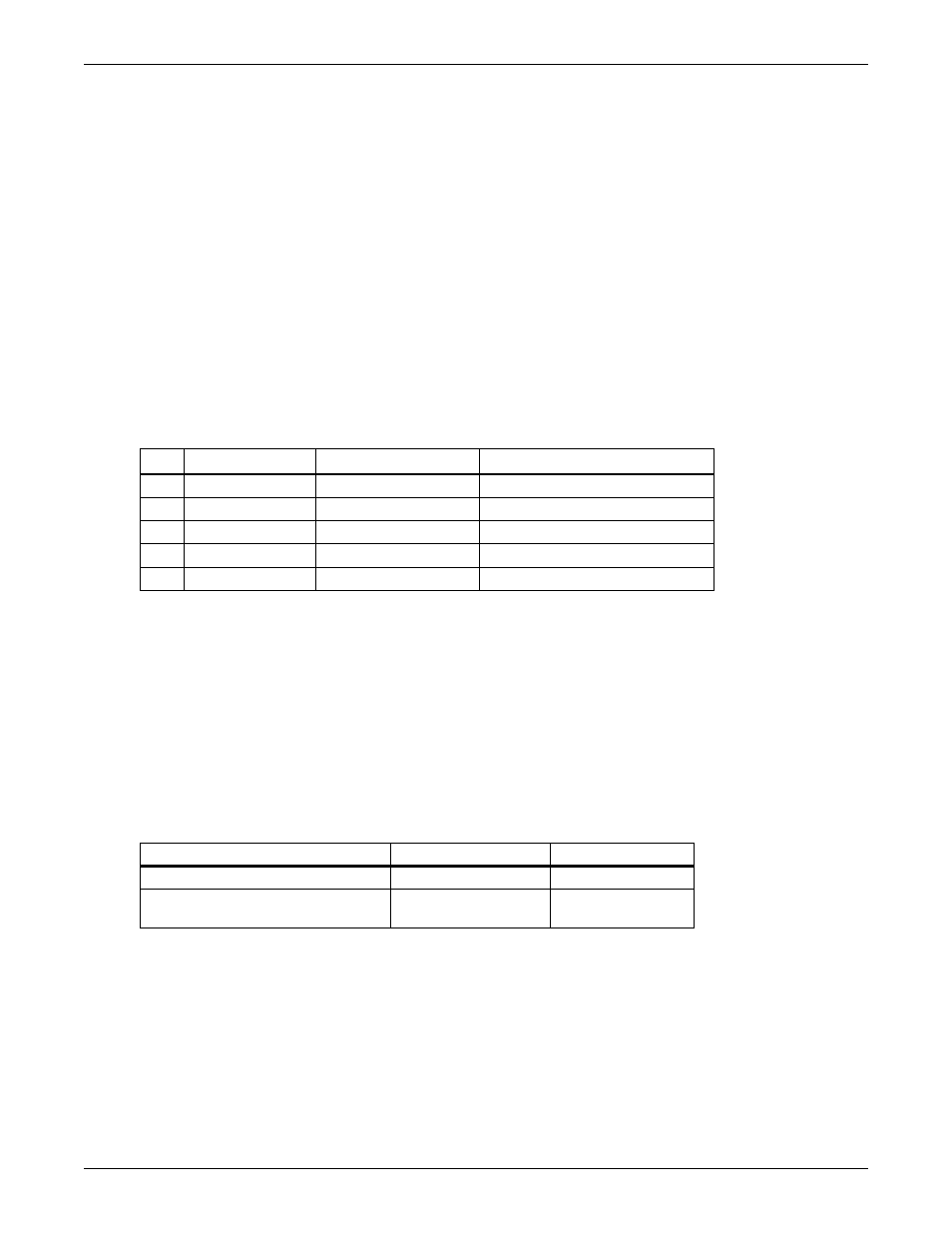

Table 13

Recommended test equipment and tools

Qty

Test Equipment

Manufacturer

Model or Type

1

Oscilloscope

Tektronix, H-P or Fluke

DC to 50 MHz

2

Voltage Probes

Tektronix, H-P or Fluke

10X, with 10 ft cable

2

Voltage Probes

Tektronix, H-P or Fluke

100X, with 10 ft cable

1

Digital Multi-meter

Fluke

87, with test leads

1

Tool Kit

N/A

Standard electrical contractor tools

Table 14

Projected component life, replacement schedule

Component

Expected Life

Replace in:

Power DC filter capacitors

About 7 years

5-6 years

Air filters, disposable

(see also 7.6 - Optional Air Filters)

1-3 years

Check 4 times/year