Continue process for duration of bore, Machine diagnostic codes, Diagnostic light – Ditch Witch JT60AT User Manual

Page 158: Code severity levels, Jt60/jt60 all terrain operator’s manual

Systems and Equipment - 158

JT60/JT60 All Terrain Operator’s Manual

Continue process for duration of bore.

4.

The tracking specialist will:

•

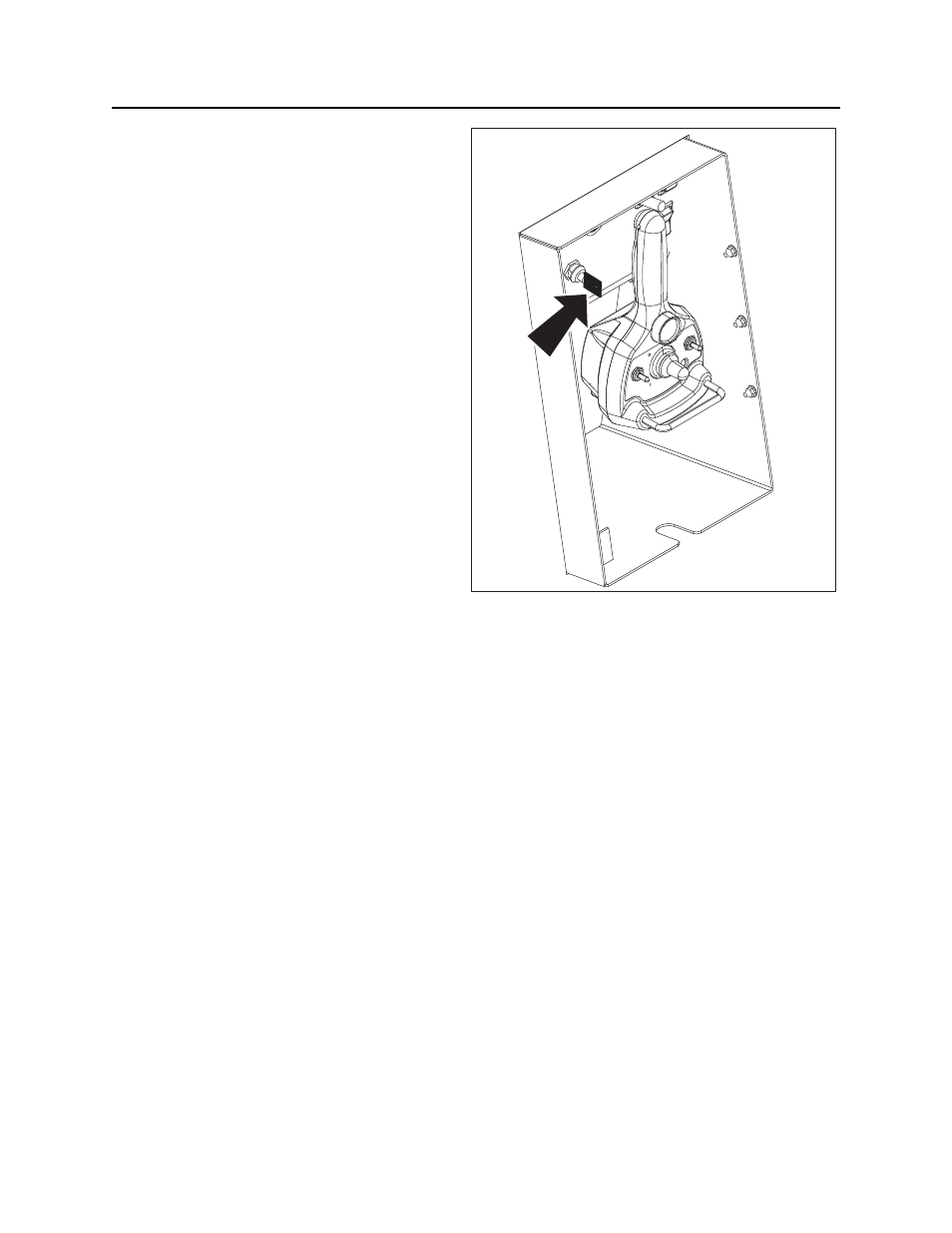

Turn the tracker control key to the ON

position (shown) to disable thrust and

rotation.

•

Insert a section of wireline through the

pipe in the shuttles.

•

Splice one end of the new wire to the

wireline in the clamped pipe.

•

Insert the other end (rear of machine)

through the spindle, gearbox, and

water swivel.

•

Turn the tracker control key to the OFF

position to enable thrust and rotation.

5.

Use the pipeloading controls to move the

new pipe into position and makeup the

joint.

6.

The tracking specialist will:

•

Turn the tracker control key to the ON

position (shown) to disable thrust and

rotation.

•

Remove slack in the wireline.

•

Secure the wireline at the spindle.

•

Connect the wireline to the offboard

computer.

•

Turn the tracker control key to the OFF position to enable thrust and rotation.

7.

Install next new section of pipe.

Continue process for duration of bore.

Machine Diagnostic Codes

Diagnostic Light

Use the red diagnostic light to learn the condition of the diagnostic system. Under normal operating

conditions, the diagnostic light will light steadily for two seconds after ignition is turned on to indicate light is

working. It will then go out and remain out unless a diagnostic code is recorded.

If diagnostic codes are detected, the diagnostic light will either flash on and off for 10 seconds to indicate a

non-essential code or remain on and flash off every three seconds to indicate an essential code. If the light

remains on, power to the controller has been lost.

Code Severity Levels

Diagnostic codes are given one of two levels of severity.

j34om014w.eps