Venting configurations, Venting materials – A.O. Smith 960 through 967 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BTH S E R V I C E H A N D B O O K

I N S T A L L A T I O N

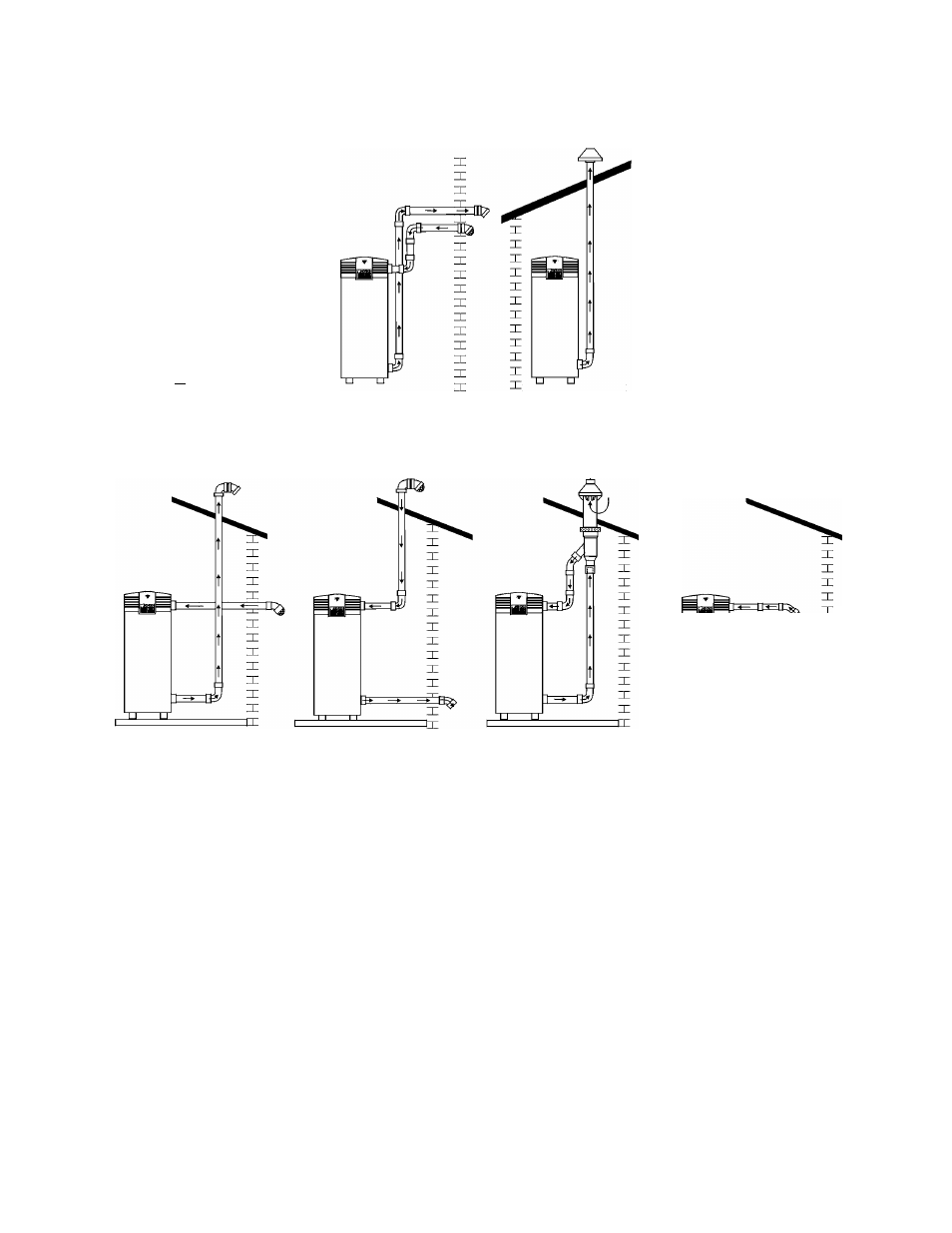

VENTING CONFIGURATIONS

z[#

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

—p l_l

l_l

SEALED DIRECT

VENT VERTICAL

SEALED DIRECT

VENT SIDEWALL

INDOOR CONVENTIONAL

VERTICAL

LE

IE

EE

EE

EE

EE

EE

EE

EE

EE

INDOOR CONVENTIONAL

SIDEWALL

SEALED DIRECT VENT

HORIZONTAL INTAKE

VERTICAL EXHAUST

SEALED DIRECT VENT

VERTICAL INTAKE

HORIZONTAL EXHAUST

SEALED DIRECT VENT

W/ CONCENTRIC VENT

VERTICAL TERMINATION

=

EE

SEALED DIRECT VENT

W/ CONCENTRIC VENT

HORIZONTAL TERMINATION

VENTING MATERIALS

This unit can be vented using only PVC (Class 160, ASTM D-2241; Schedule 40, ASTM D-1785; or

Cellular Core Schedule 40 DWV, ASTM F-891), Schedule 40 CPVC (ATSM F-411), or ABS (ASTM

D-2661) pipe. The fittings, other than the TERMINATIONS should be equivalent to PVC-DWV fit

tings meeting ASTM D-2665 (Use CPVC fittings, ASTM F-438 for CPVC pipe and ABS fittings,

ASTM D-2661/3311 for ABS pipe. If CPVC or ABS pipe and fittings are used, then the proper

cement must be used for all joints, including joining the pipe to the Termination Tee (PVC Material).

PVC Materials should use ASTM D-2564 Grade Cement; CPVC Material should use ASTM F-493

Grade Cement and; ABS Materials should use ASTM D-2235 Grade Cement.

For water heaters in locations with high ambient temperatures (above 100°F) and/or insufficient

dilution air, it is recommended that CPVC or ABS pipe and fittings (MUST USE SUPPLIED VENT

TERMINAL) be used.

A. O. Smith Water Products Co.

Ashland City, Tennessee © 2004

Technical Training Department

TC-044 Revision 6