Error codes – A.O. Smith 960 through 967 User Manual

Page 42

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BTH S E R V I C E H A N D B O O K

E R R O R C O D E S

ERROR CODES

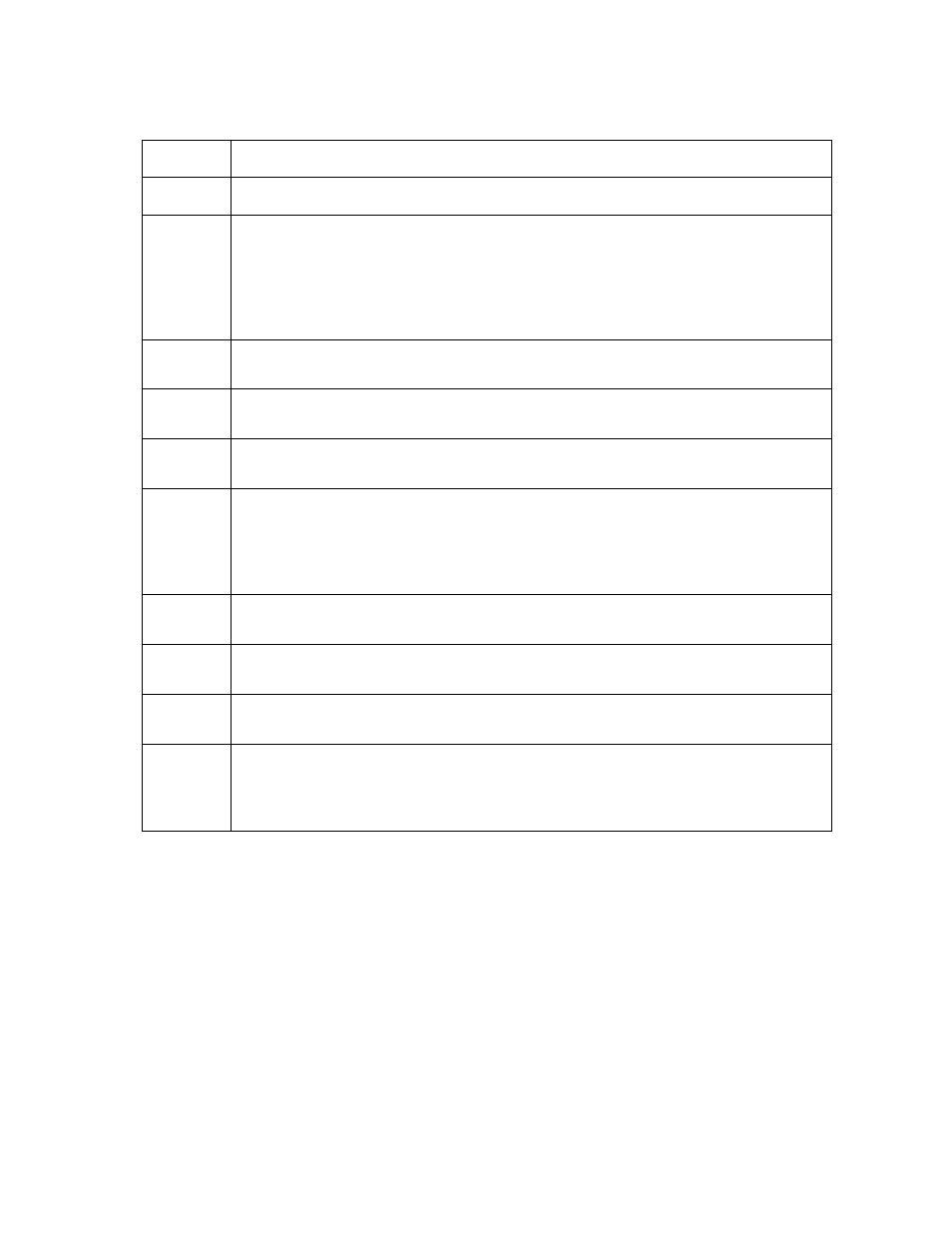

CODE

INDICATION

00

This is normal operation, 00 is displayed each time the heater is powered up.

01

Indicates the pressure switch circuit was not open during the prediagnostic system

check when the proper state of the Draft Prover Switches are verified. The Blower

Prover Switch is normally open, the circuit should therefore be open during the

prediagnostic system check at the beginning of each cycle. Check Blower Proving

Switch for continuity with the blower off, there should be no continuity, check

pressure switch wiring.

02

Indicates the heater faiied to light after 3 trials. Check ignitor, gas pressure, blower

speed reduction on BTH 250.

04

Indicates the ECO is open. Check water temperature in tank, ECO will open at 202°

F and can be reset below 160° F.

05

Indicates a Temperature Probe is open. Check both probes for proper resistance

and continuity.

11

Indicates the Pressure Switch Circuit did not close after blower was energized.

Check normally open Blower Prover Switch operation, check normally closed

Blocked Outlet, Inlet, and Low Gas pressure (BTH 120 and 250 only) to ensure they

remain closed. Check for blocked vent pipe (s) or if equivalent feet venting limits have

been exceeded.

15

Indicates temperature sensed by probe(s) is out of bounds, reading is less than

30° F. Check resistance of temp probes, check water temperature in tank.

22

Indicates Ignition Reiay faiiure. Should be off and it is on. Try resetting, turn power

off and on, if code remains, replace board.

25

Indicates temperature sensed by probe(s) is out of bounds. Reading is more than

220° F. Check resistance of temp probes, check water temperature.

CODE #S

ABOVE

199

Internai software or hardware errors, electrical line noise can cause erratic

operation and these error codes. Try adding a “line fiiter” (available from electrical

suppliers) to the 120 VAC power supply. If these errors codes persist or the control

cannot be reset, replace the control board.

All these errors cause a “soft” lockout with the exception of 04 -

ECO, which is a “hard” lockout. Soft lockouts will reset automati

cally after 60 minutes or if the reset button is pushed at any time.

The ECO lockout, error code 04 will have to be manually reset by

pushing the rest button after water in the tank has cooled below

160° F.

A. O. Smith Water Products Co.

Ashland City, Tennessee © 2004

41

Technical Training Department

TC-044 Revision 6