Pressure operated capacity control valve operation, 06d,07d, Carrier – Carrier 07D User Manual

Page 31: Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Carrier

INSTALLATION

06D,07D

Pressure Operated Capacity Control Valve

Operation

This valve is self-contained in that no wiring

or external controls such as pressurestats or

thermostats are needed as on the solenoid ca

pacity control valve.

This valve is interchangeable with the sole

noid capacity control valve now used on the

6D compressors.

It is also interchangeable between the 06D and

06E compressors.

This valve is a self-actuated cylinder head by

pass type which is suction pressure operated.

The valve operation is such that the controlled

cylinders will not load up until a differential

of 25 psi between suction and discharge pres

sure is established.

There can be a control valve in each side bank

of the six cylinder compressors. Each of the

control valves will load or unload two cylinders

in a single bank of the compressor by allowing

the discharge gas to bypass to the suction side

thru the bypass port. The unloaded cylinders

then operate thru no pressure differential, thus

consuming very little power.

When the suction pressure drops due to decrease

in load, the poppet valve will snap open, as shown

in Fig. 25A. The discharge gas behind the piston

will now bleed out to the suction manifold, re

ducing the pressure behind the bypass piston and

allowing the bypass piston spring to pull the pis

ton back against the valve body. The bypass pis

ton port will then open allowing discharge gas

to recirculate back to the suction manifold.

When the suction pressure is above the valve

set point, the poppet valve will be closed, as

shown in Fig. 25B. Discharge gas will now bleed

into the valve chamber. The pressure will then

overcome the bypass valve spring tension and

force the piston forward, sealing the bypass

port. The two cylinders controlled by this valve

will now run fully loaded.

The check valve in the valve plate will close

when the cylinder bank is unloaded, isolating the

individual cylinder bank from the discharge man

ifold. When the bank loads up, the discharge gas

pressure will force open the check valve, allow

ing the gas to pass into the discharge manifold.

Pumpdown control is NOT recommended when

using these valves because of a bleed in the

differential chamber. This device will equalize

the compressor upon shutdown within 50 psi dif

ferential very quickly so that on start-up the

compressor will have very little head pressure

to start against. There is a possibility of short

cycling on pumpdown because of a short equal

ization time. Therefore, we recommend single

pumpout or liquid line solenoid drop with crank

case heaters.

The control load up or set point (Fig. 26) is ad

justable from -40 F (0-psig) to +50 F (85-psig)

and is set in the field for individual job require

ments. The set point adjustment is made by

turning clockwise to increase the control pres

sure (load up) and counterclockwise to decrease

the control pressure point.

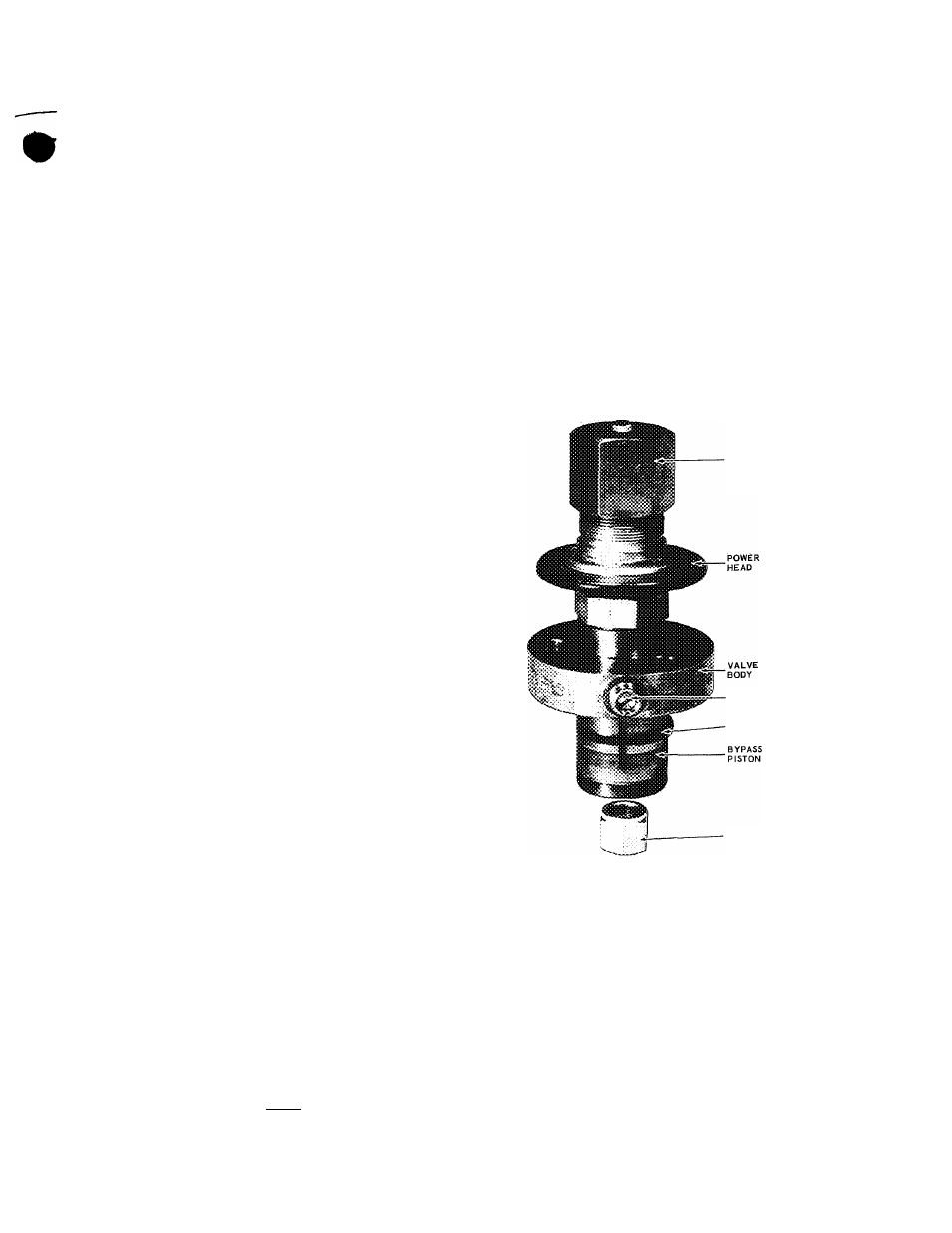

SET POINT

ADJUSTMENT

DIFFERENTIAL

ADJUSTMENT

BYPASS

PISTON RING

DIFFERENTIAL

SCREW

SEALING CAP

Fig. 26 - Capacity Control Valve

To Adjust - The set point head should be turned

clockwise down to the bottom stop. The coun

terclockwise turns can be determined by using

the curve in Fig. 27. If the desired load up point

is known, the number of turns can be picked

off the curve.

The differential adjustment (Fig. 26) will vary

the pressure difference between the cut-in and

cutout point from 6- to 22-psi. This differential

adjustment is made by removing the sealing

cap and turning the inside screw clockwise to

increase the differential and counterclockwise

to decrease the differential.

31