Lubrication, Water valve adjustment (water-cooled units only), Factory oil charge – Carrier 07D User Manual

Page 28: Solenoid valve electrical characteristics, 06d,07d, Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

06D,07D

INSTALLATION

blocking the air flow on air-cooled units, allow

ing the head pressure to rise gradually. The

cutout and cut-in pressures should be within

10- to 15-pounds of the values shown in Table 6.

If they are not, the pressurestat should be re

placed or adjusted if it is an adjustable type.

Check the low-pressure cutout by closing the

suction shut-off valve or by closing the liquid

line shut-off valve to allow the compressor to

pump down. The cut-in and cutout points may

be adjusted if necessary.

Lubrication

A properly adjusted compressor should run with

the crankcase warm to the touch. Check oil level

frequently to see that a sufficient amount of oil

remains in the crankcase. Check the oil pres

sure by looking thru the crankcase sight glass

at the oil pressure relief valve, (For 2 cylinder

compressors, see Fig, 22.) If oil is discharged

from the relief valve, pressure is adequate.

To check the oil charge on 2 cylinder 6D com

pressors, proceed as follows;

1. Pump down the compressor, turn off power

and close the shut-off valves.

2. Remove the suction manifold pressurestat

connection and half-union coupling.

3. Insert a dipstick in the hole and measure the

oil charge.

Below is a sketch of a simple dipstick that may

be used on 2 cylinder 6D compressors.

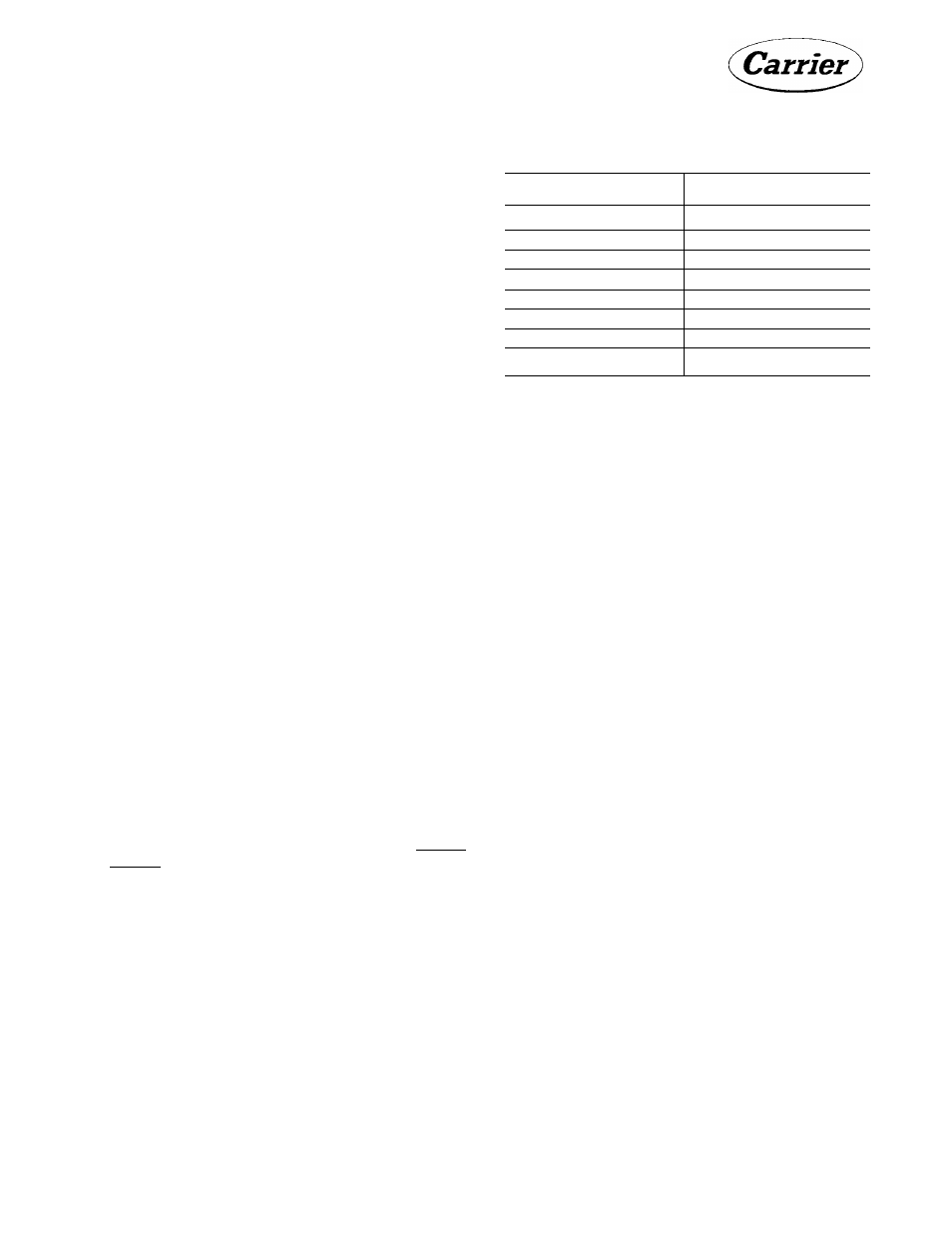

Table 7 - Factory Oil Charge (Pts)

Compressor

Oil Charge

06DA109

3-1/2

06DA808

3-1/2

06DA013

5

06DA718

7

06DA518

7

06DA724

10

06DA337

10

06DA537

10

ADDING OIL

1. Pump down the compressor to 2-psi gage; stop

the compressor and close shut-off valves.

2. Add oil thru the low-side pressurestat con

nection or the oil fill plug on 6 cylinder

compressors.

NOTE: Be sure to connect the low-side

equipment and to size the piping, so oil

will return to the compressor under

all operating conditions.

Water Valve Adjustment (Water-Cooled Units

Only)

Adjust the water regulating valve to the most

economical head pressure for the locality. Nor

mally this is between 120- and 140-psi for R-12

and between 200- and 230-psi for R-22,

Factory Oil Charge

The unit compressors are shipped with the oil

charges of PP33-2 oil shown in Table 7. Do not

assume that the charge is sufficient. Run the^

unit for 15- to 20-minutes until conditions have*

leveled off. Stop the compressor without pump

ing down and immediately check the oil level.

The oil level must be 1/3 to 2/3 of the way up

on the sight glass. If the oil level is low, add oil.

PRESSURESTAT BOSS TO END OF STICK

------- MIN OIL LEVEL- 4^/16

r

NORMAL

OIL

LEVEL-3k4-

M AX OIL LEVEL - 3 ^''16 —

Fig. 22 - Oil Level Measurement 2 Cylinder

Compressors

07DA210,112,215 ELECTRICALLY OPERATED

CAPACITY CONTROL DEVICE

The Capacity Control Device is a cylinder head

bypass type, solenoid operated. Energizing the

control solenoid unloads a complete cylinder

bank and de-energizing the solenoid loads a

complete cylinder bank.

Controls to operate the solenoid valve are not

furnished with the 07DA210,112,215 condensing

units. They must be field furnished and may be

either temperature or pressure operated as per

job requirements.

Solenoid Valve Electrical Characteristics

208/220 volts

1

(/>

60 cycle 10 4 VA holding

41 6 VA inrush

220 volts

1 0 50 cycle 10 4 VA holding

41.6 VA inrush

115 volts

1 0 60 cycle 10.4 VA holding

41.6 VA inrush

28