Description and use of the vacuum indicator, Procedure for dehydrating the system, 06d,07d – Carrier 07D User Manual

Page 25: Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLATION

06D,07D

Before dehydrating a system make the following

preparations:

1. Obtain a pump that will produce a vacuum of

0.2 in. Hg absolute. Do not use the compres

sor as a vacuum pump. It is not designed for

such use and may be seriously damaged.

2. Pressure test the system to be sure it is

free of leaks.

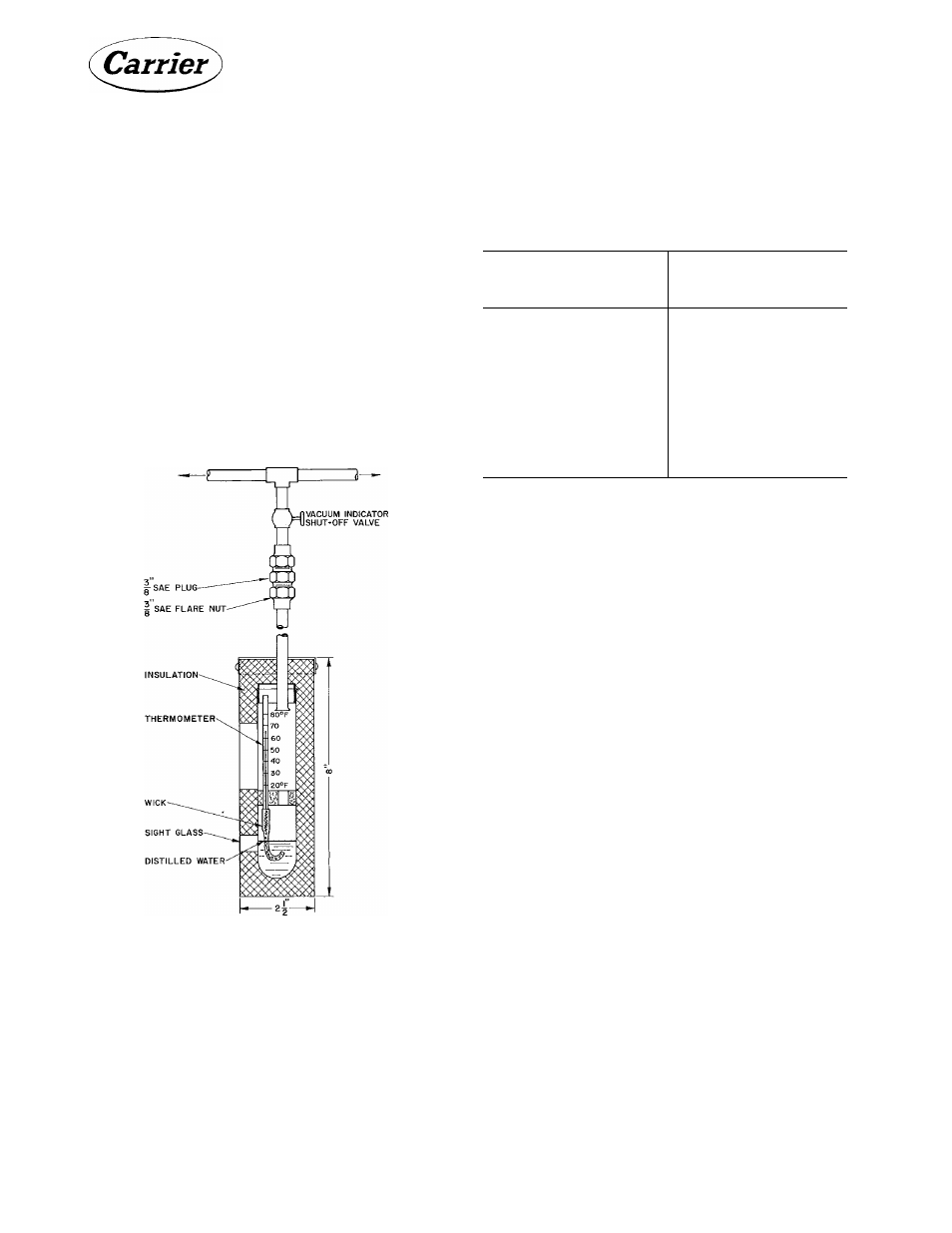

3. Obtain a vacuum indicator similar to that

shown in Fig. 20 (available from Robinair

Manufacturing Corporation, Edgerton, Ohio).

4. Keep the ambient temperature above 60 F to

speed the evaporation of moisture.

TO

COMPRESSOR

TO VACUUM PUMP

SHUT-OFF VALVE

Fig. 20 - Vacuum Indicator

Description and Use of the Vacuum Indicator

The vacuum indicator consists of a wet-bulb

thermometer in an insulated glass tube con

taining distilled water. Part of the tube is ex

posed so the thermometer can be read and the

water level checked. When the vacuum indicator

is connected to the vacuum pump suction line,

the thermometer reads the temperature of the

water in the tube. The temperature is related

to the absolute pressure in the tube. Table 5

gives the absolute pressures corresponding to

various temperatures.

Table 5 - Vapor Pressures of Water

Temp F Observed on

Vacuum Indicator

Absolute Pressure

Inches of Mercury

70

0.739

60

0.522

55

0 436

50

0 363

45

0.300

40

0.248

35

0 204

32

0.180

NOTE:

To determine the vacuum in inches of mercury,

subtract the absolute pressure from the barometer

reading.

Handle the vacuum indicator with care. It must

be vacuum tight to give a true reading. The top

seal of the indicator is not designed to support

a long run of connecting tubes. Faster the tubes

to supports to prevent damage.

Use only distilled water in the indicator. Be

sure the wick is clean. Oil or dirt on the wick

causes erroneous readings.

To prevent loss of oil from the vacuum pump

and contamination of the indicator:

1. Install a shut-off valve in the suction line at

the vacuum pump.

2. Install a shut-off valve in the suction line at

the vacuum indicator (Fig. 20).

3. When shutting off the pump, close the indica

tor valve and the pump valve, and turn off

the pump in that sequence.

Procedure for Dehydrating the System

1. Connect the pump and vacuum indicator to

the system. Put a "jumper" line between

the high and low side so that the pump will

draw a vacuum on all portions of the system.

Open the compressor shut-off valves. Start

the pump.

2. Open the indicator connection shut-off valve

occasionally and take a reading. Keep the

25