06d,07d, Carrier, Installation – Carrier 07D User Manual

Page 22

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

06D,07D

INSTALLATION

Carrier

■ L|

EVAPORATOR

INTERLOCK

CONTACTS,N.O.

----

OFF

CONO AUX

---

LOW

PRESS.

SWITCH

CONTROL

THERMOSTAT

---------

*^^-0------

SAFETY

DEVICE

CONTACTS,N.C.

PUMPOUT RELAY

M" AUX

J/_

CONTACTS,N.OT

POR

CONTACTS,N.O.

TR

TR

CONTACTS, N.O.

4^—---------

LIQ SOL VALVE

CONTACTS,N.C.

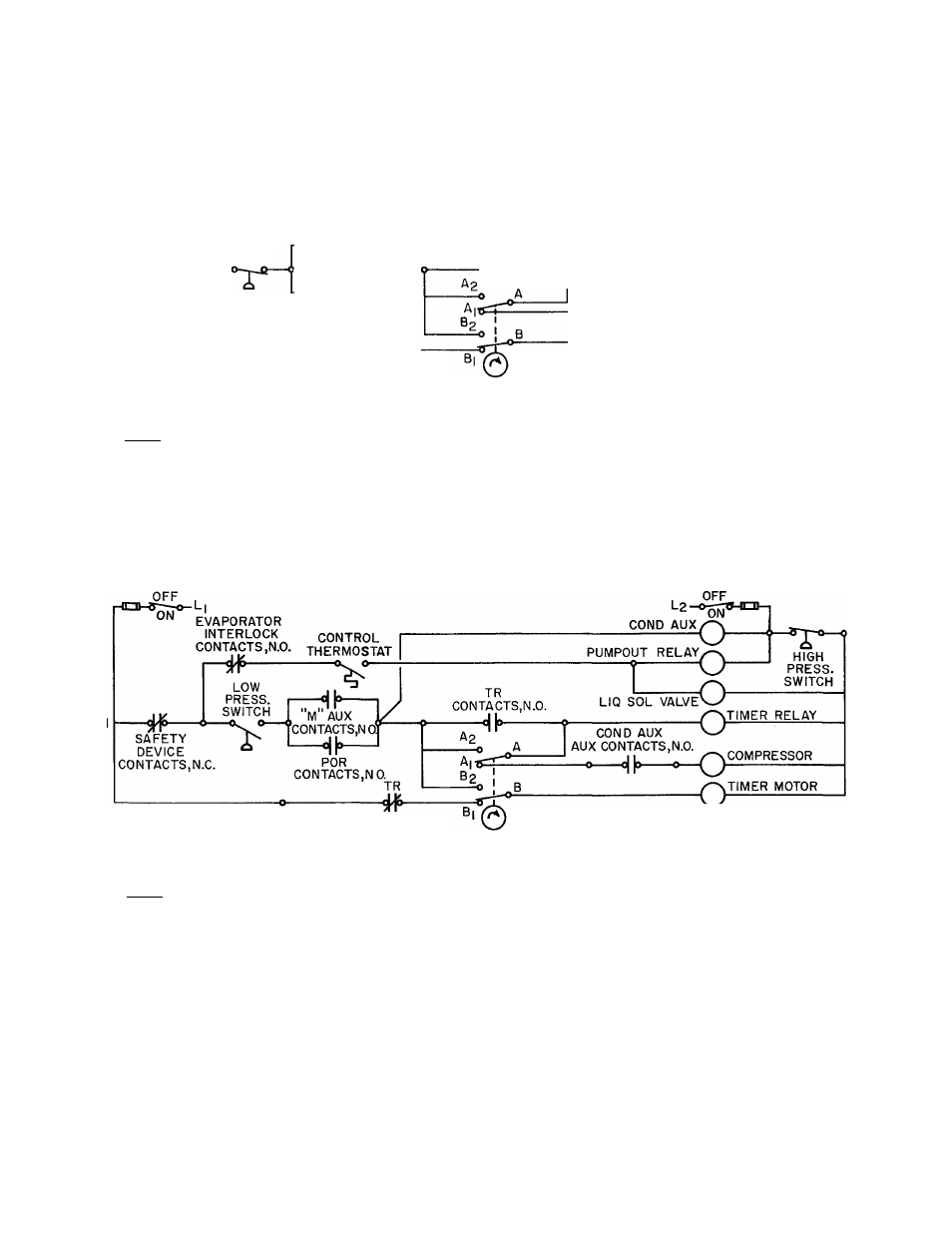

2. Operating Condition

Time: 0 Min 15 Sec

Timer switch plunger has dropped off the

cam node and the contacts have switched to

positions A-Ai and B-Bi. Timer motor stops

running since TR N.C. contacts are open.

O

O-

a

■ Ö

—Cj-O—<•

HIGH

PRESS..

SWITCH

TIMER RELAY

COND AUX

AUX CONTACTS,NO.

—

#—

COMPRESSOR

TIMER MOTOR CAM

1/5 RPM, 15 SEC CAM NODE

O

TIMER MOTOR

Timer relay (TR) remains energized thru

TR N.O. contacts, which are now closed.

Compressor motor starter is energized thru

timer switch contacts A-Ai and compressor

starts. Compressor continues to run unless

circuit is broken by action of control ther

mostat or safety devices.

Operating Condition of Time Guard Control (Single Pump-Out Arrangement Shown)

CONTACTS, N.C.

3. Stopping Sequence

Time: Any time after 15 seconds

Timer switch plunger is still in position of

having just dropped off the cam node, since

timer motor has not been running, and switch

contacts are in position A-Ai and B-Bi.

Thermostat opens when cooling load is sat

isfied. Liquid solenoid valve (SV) is de

energized and closes. Pumpout relay (POR)

is de-energized, and its contacts open. The

timer relay (TR) and compressor continue

to operate thru compressor starter auxiliary

contacts ”M" until system pumps down and

low-pressure switch opens. Then compres-

TIMER MOTOR CAM

1/5 RPM, 15 SEC CAM NODE

sor and condenser auxiliaries stop and relay

TR is de-energized. TR N.C. contacts close

and timer motor (TM) is energized thru

switch contacts B-Bi and starts to run.

The TM timer will switch again to position

A-A2 and B-B

2

after 4 min 45 sec elapse.

Thus, at least 4 min 45 sec must elapse after

a shutdown before the compressor can begin

its restart sequence, if the cooling thermo

stat is closed. A total of 5 min will elapse

before the compressor can restart. Each

compressor restart is preceded by 15 sec

operation of the condensing equipment.

This reverts to conditions at time 0 min 0 sec.

Stopping Sequence of Time Guard Control (Single Pump-Out Arrangement Shown)

22