The halide leak detector, Leak test the system, Dehydrate the system preparation – Carrier 07D User Manual

Page 24: 06d,07d, Carrier, Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

06D,07D

INSTALLATION

Carrier

COOLING TOWER OR

CITY WATER

COOLING TOWER

CITY WATER

COOLING TOWER

CITY WATER

PRECAUTIONS: Do not use the compres

sor to build up pressure. If used to com

press air, overheating and damage may

result.

DO NOT USE OXYGEN TO BUILD UP PRES

SURE. Use a refrigerant or a dry stable gas

such as nitrogen or carbon dioxide instead.

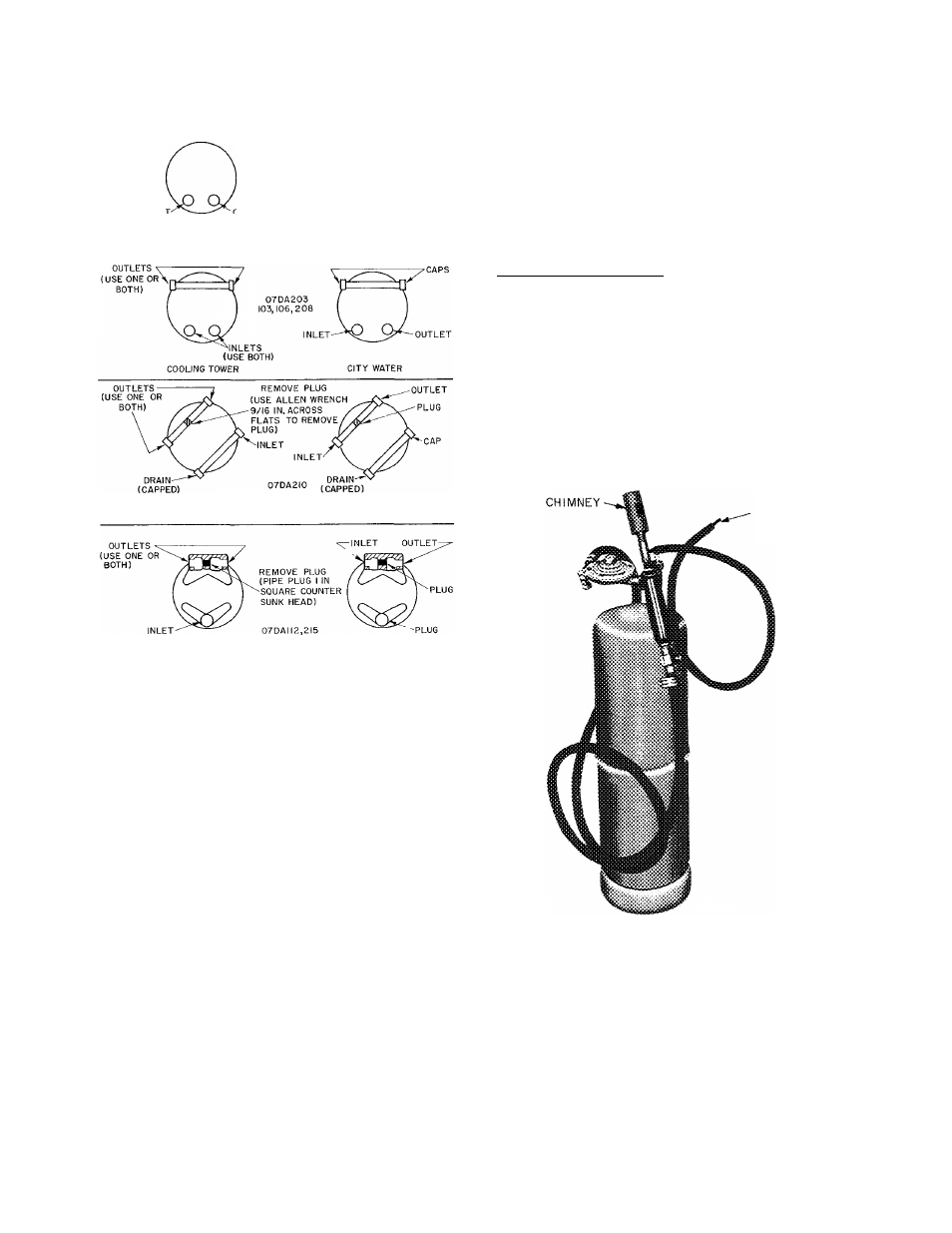

The Halide Leak Detector

The halide leak detector in Fig. 19 consists of a

burner, needle valve, suction tube, and a chim

ney with a copper reaction plate. Some torches

use alcohol and others propane as fuel.

To use the leak detector:

1. Adjust the flame so the top of the flame cone

is level with or slightly above the chimney.

2.

Place the end of the suction tube at the point

to be tested. The tube pulls in a sample of

air to the burner where the refrigerant is

decomposed by reaction with the copper plate.

3. Observe color of the flame. Small leaks give

a greenish tint and large ones a vivid blue.

Fig. 18 - Water-Cooled Condensing Units

Condenser Water Connections

LEAK TEST THE SYSTEM

1. Charge the system to 40 psi with dry nitrogen

or carbon dioxide. Check all joints for large

leaks with soap solution.

2. Release the pressure and charge to 10 psi

with refrigerant.

3. Add dry nitrogen or carbon dioxide until the

pressure is 150 psi.

4. Check for leaks with a halide leak detector.

5. Repair leaks and purge system.

SUCTION

FEELER

TUBE

Fig. 19 - Halide Leak Detector

DEHYDRATE THE SYSTEM

Preparation

Moisture in the system causes oil sludge and

corrosion. It is likely to freeze up the expansion

valve of a low temperature system. The best

means of dehydration is evacuation with a pump

especially built for this purpose.

#

24