Checking operations, Dual pressurestat, Initial start-up instructions – Carrier 07D User Manual

Page 27: Water-cooled units, 06d,07d, Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLATION

06D,07D

crack open the liquid test cock. The charge

is sufficient if a mixture of liquid and vapor

comes from the test cock.

The sight glass method of checking the re

frigerant charge is more reliable, and should

be used whenever possible.

6. When the system is sufficiently charged, close

the valve to the refrigerant cylinder, back

seat the suction shut-off valve, disconnect

the charging line, plug the gage ports, and

recap the valve stems. If the pressure in

the cylinder drops to the level of the suction

pressure, all refrigerant can be drawn from

the cylinder by frontseating the suction shut

off valve and pulling a vacuum on the cylinder.

CAUTION: Be careful not to overcharge the sys

tem, Overcharging results in:

1. Higher discharge pressure due to excess liq

uid in the condenser. With water-cooled units

this means higher cooling water consumption.

2. Possible compressor damage,

3. Higher power consumption,

4. Increased flooding of refrigerant to the com

pressor during off-cycle if the expansion

valve is leaky.

To charge the system thru the liquid line, refer

to the Service Section of the Product Informa

tion Book.

3. Open the compressor discharge and suction

shut-off valves,

4. Open the liquid line valve at the receiver.

5. Open pressure line valve of the water reg

ulating valve.

6. Close the main power switch supplying cur

rent to the compressor starter,

7. Check the oil pressure. (See "Lubrication.")

8. Adjust the water regulating valve.

9. Check control settings.

10. Recheck the oil level in the crankcase.

11. Cap all valves tightly.

CHECKING OPERATIONS

When starting a newly Installed compressor, be

on the alert for any sign of trouble. Always in

stall suction and discharge pressure gages. The

water regulating valve on water-cooled units

may need adjustment.

Dual Pressurestat

A dual pressurestatis connected to both the high

side and low side to protect the compressor.

Settings are preset at the factory for use with

R-12 or R-22 as shown by the values in Table 6.

INITIAL START-UP INSTRUCTIONS

The compressor should be started up only by

a refrigeration mechanic who is familiar with

accepted operation practices for refrigeration

systems. Detailed instructions for checking and

adjusting the components will be found under

"CHECKING OPERATIONS."

Proceed as follows:

Water-Cooled Units

1, Check to see that the proper oil level appears

in the compressor sight glass, (A dipstick

must be used with two cylinder compres

sors.) See "Lubrication" under "CHECK

ING OPERATIONS,"

2, Open the main water supply valve and allow

water to reach the condenser.

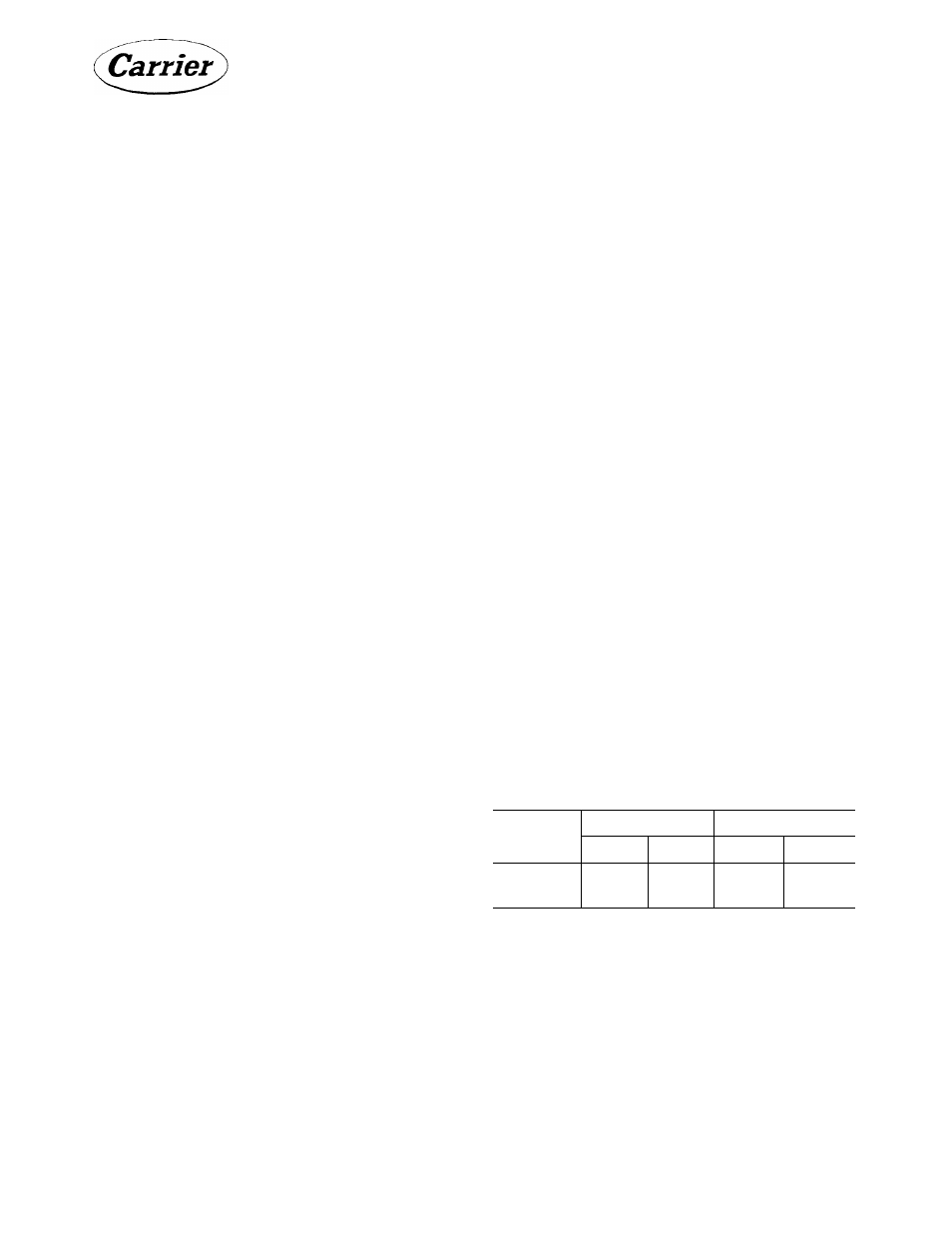

Table 6 - Factory Pressurestat Settings (Psig)

High Pressure

Low Pressure

Unit

Cutout

Cut-in

Cutout

Cut-in

07D Units

280

200

36

67

U6U Units

370

290

36

67

The 07D condensing unit high pressurestat cut

out point is adjustable from 230-340 psig with

a fixed differential. The 06D compressor unit

high pressurestat cutout point is adjustable from

230-400 psig with a fixed differential. The low

pressurestat on all units have an adjustable cut

out from 20" vacuum to 70 psig and an adjust

able differential from 13-50psi. All adjustments

are made thru the back of the control box.

Check the high-pressure cutout by throttling

the condenser water on water-cooled units, or

27