Piping and accessories, Elimination of pipe vibration, Time guard control operation – Carrier 07D User Manual

Page 20: 06d,07d, Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

06D,07D

INSTALLATION

PIPING AND ACCESSORIES

Elimination of Pipe Vibration

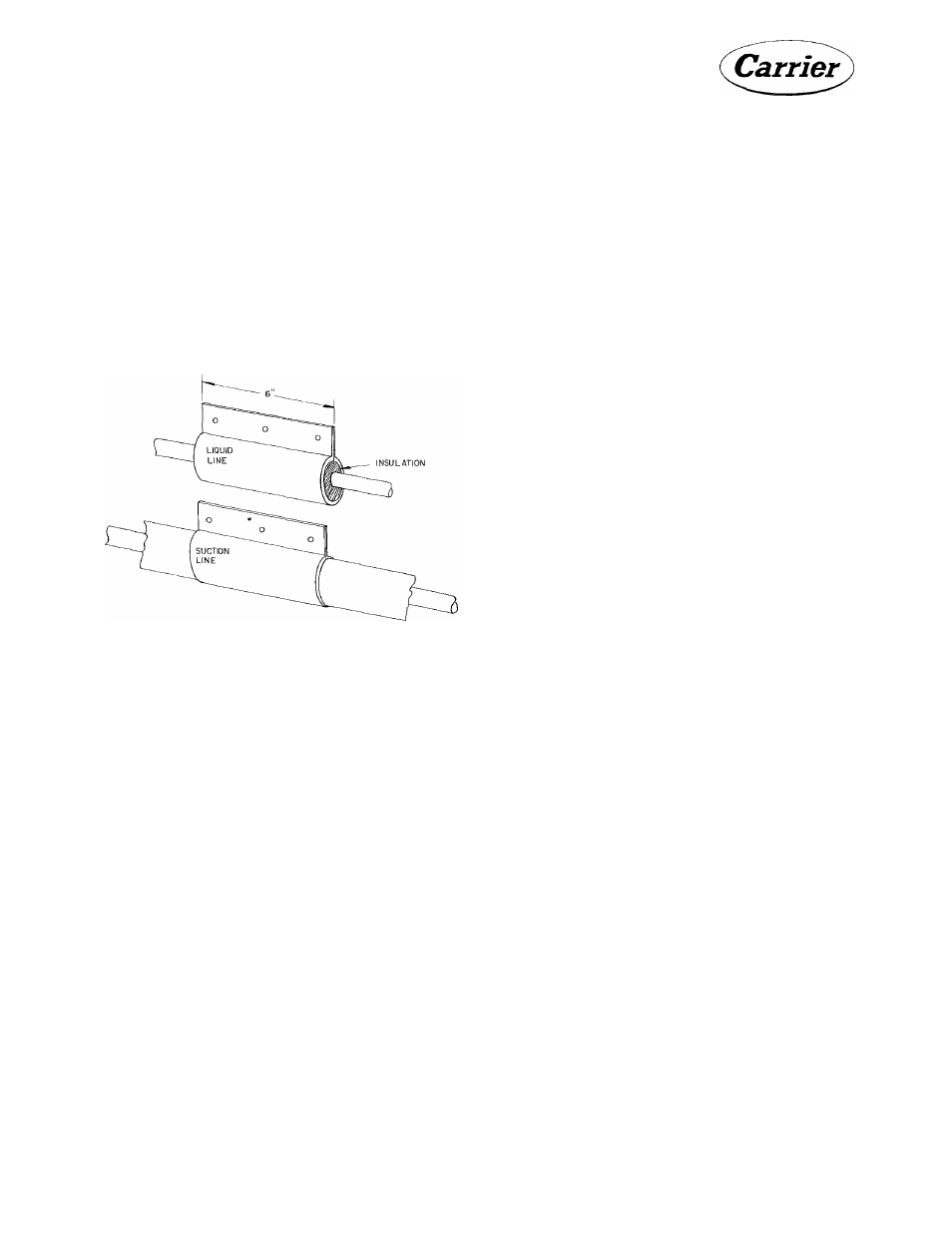

The liquid and suction lines are usually of soft

copper tubing. To absorb vibration, loop or

sweep tbe liquid and suction lines near the unit.

Fasten the tubing to walls or supports, using

vibration isolation type bangers as shown in

Fig. 17. Keep uninsulated lines away from hot

water or steam lines. Follow the piping prac

tices in Carrier System Design Manual, Part 3.

Fig. 17 - Refrigerant Line Hangers

Time Guard Control Operation

CONTROL CIRCUIT

This unit is equipped with controls which pro

vide automatic reset overload protection, time

delay in starting, and controlled cycling under

any cycling condition. Following shutdown of

the compressor for any reason (i.e., opening,

of the thermostat, functioning of a protective

device, power failure), the control permits re

starting of the compressor only after a five

minute period has elapsed. On normal starts,

the control will operate 15 seconds before start

ing the compressor.

The heart of the control is the cycle timer. The

cam on the cycle timer completes one revolu

tion in five minutes. Whenever the compressor

is stopped the timer motor will automatically

run until the cam lever is operated, which in

turn actuates the necessary switches. When this

sequence is completed, the cycle timer is pre

pared to start the unit.

Table 4 shows the normal operating sequence

of the timer circuit. This table can be helpful

in diagnosing electrical problems.

Operation of the control circuit is generally the

same on all voltage units. However, wiring se

quences for the individual controls may vary,

such as overloads and safety devices.

The following is a general description of the

operating sequence of the control circuit. Refer

to the schematic wiring diagrams as a guide.

The functions of this control accessory are:

1. To limit restart cycling of the compressor,

under any circumstance, to a minimum of

five minute intervals after stopping.

2. To allow time to run during normal "off

periods, thus utilizing this time as part of

the five minute timing interval described

above in No. 1.

3. To provide a 15 second delay on each com

pressor start before the compressor motor

starter is energized; to allow auxiliaries such

as condenser pump, condenser fan, chilled

water pump, etc. to be in operation before

the compressor starts. This feature will pre

vent nuisance cutouts due to momentary ac

tion of the high pressure switch or chilled

water flow switch during start-up.

20