Check refrigerant charge, 06d,07d, Carrier – Carrier 07D User Manual

Page 26: Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

06D,07D

INSTALLATION

Carrier

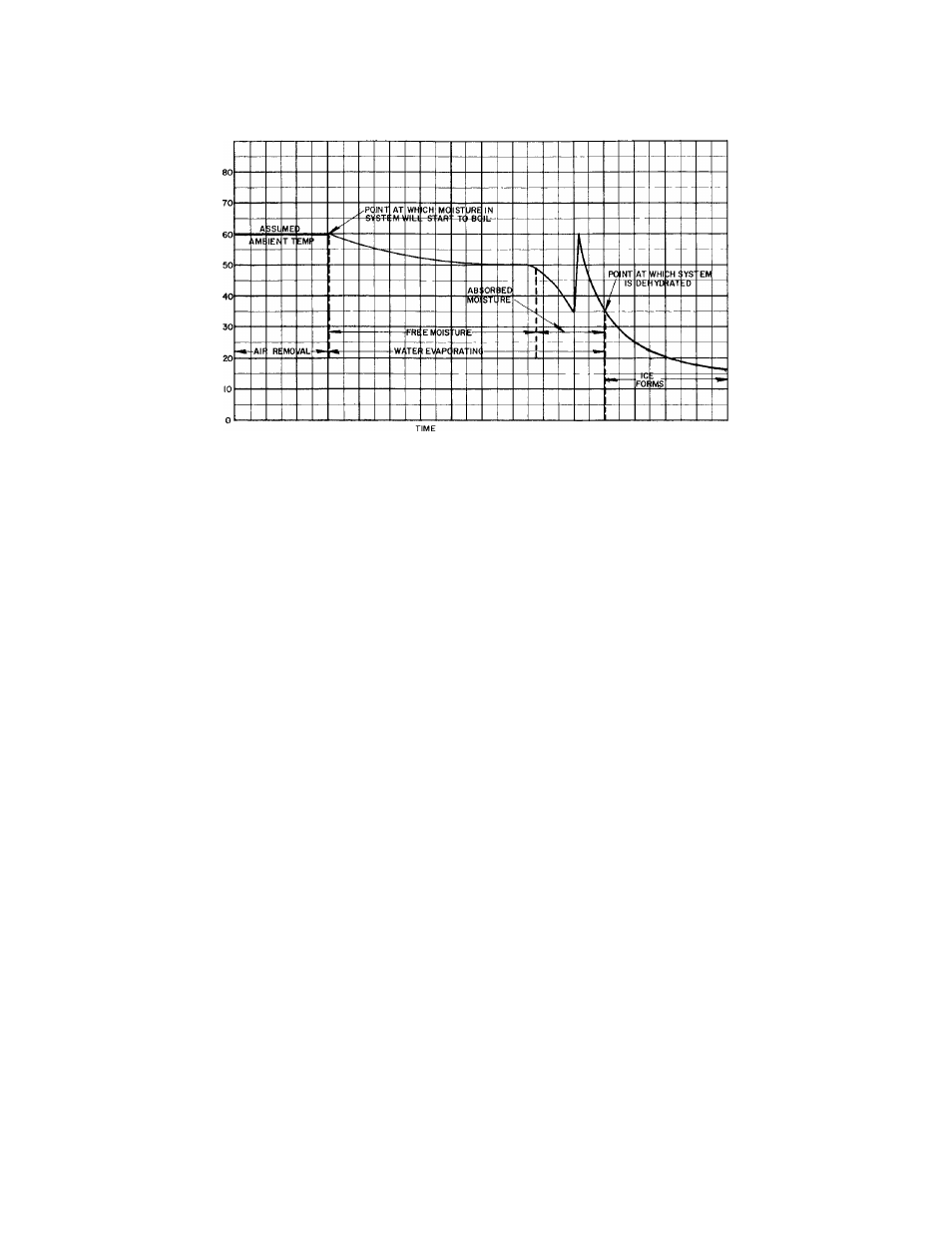

Fig. 21 - Dehydration Pull-Down Curve

valve open at least three minutes for each

reading. (Keep the valve closed at all other

times to decrease the amount of water the

pump must handle and hasten dehydration.)

When the pressure in the system drops to a

value corresponding to the vapor pressure of

the water in the indicator, the temperature

will start to drop. In the example shown in

Fig. 21, the ambient temperature and the

temperature of the water in the indicator

is 60 F. Starting at 60 F and 0 time, the

temperature of the water in the indicator

remains at 60 F until the pressure in the

system is pulled down to the pressure cor

responding to the saturation temperature of

the water (60 F). At this point the moisture

in the system will start to boil. The tem

perature drops slowly until the free mois

ture is removed, and then more rapidly until

the absorbed moisture is removed (35 F).

Dehydration is nearly completed at this point,

provided the ambient temperature remains

at 60 F or higher. If the ambient temperature

were lower than 60 F, ice might form before

moisture removal is complete.

3. Continue the dehydrating operation until the

vacuum indicator shows a reading of 35 F

which corresponds to a pressure of 0.204 in.

Hg absolute. This may take several hours. It

may be advantageous to run the pump all night.

4. With the pump still running, open the system

at a point farthest from the pump and admit

air thru a drier. Close system and repeat

Steps 2 and 3. Vapor in the system is thus

greatly diluted and almost completely re

moved by double dehydration.

5. After evacuation, turn off the pump suction

valve and break the vacuum by admitting

refrigerant.

6. Disconnect the pump and vacuum indicator.

CHECK REFRIGERANT CHARGE

After the system has been evacuated and dehy

drated, charge refrigerant in gas form into the

low side as follows:

1. Backseat the suction and discharge shut-off

valves. Install a gage in the discharge gage

port and turn the valve one turn from the

backseat position to allow pressure to reach

the gage.

2. Connect a refrigerant drum thru a drier and

tee connection with a compound gage, to the

suction gage port. Purge air from the lines

and tighten the connections.

3. Turn the suction shut-off valve a couple turns

from the backseat position and open the re

frigerant drum valve. Keep the refrigerant

drum in an upright position to prevent liquid

refrigerant from entering the compressor.

4. Start the compressor. See "INITIAL START

UP INSTRUCTIONS."

5. Check the refrigerant charge frequently while

charging, by observing the liquid line sight

glass. The refrigerant charge is sufficient

when flashing (bubbles) disappears. An al

ternate method of checking the charge is to

26