Top Flite TOPA0145 User Manual

Page 35

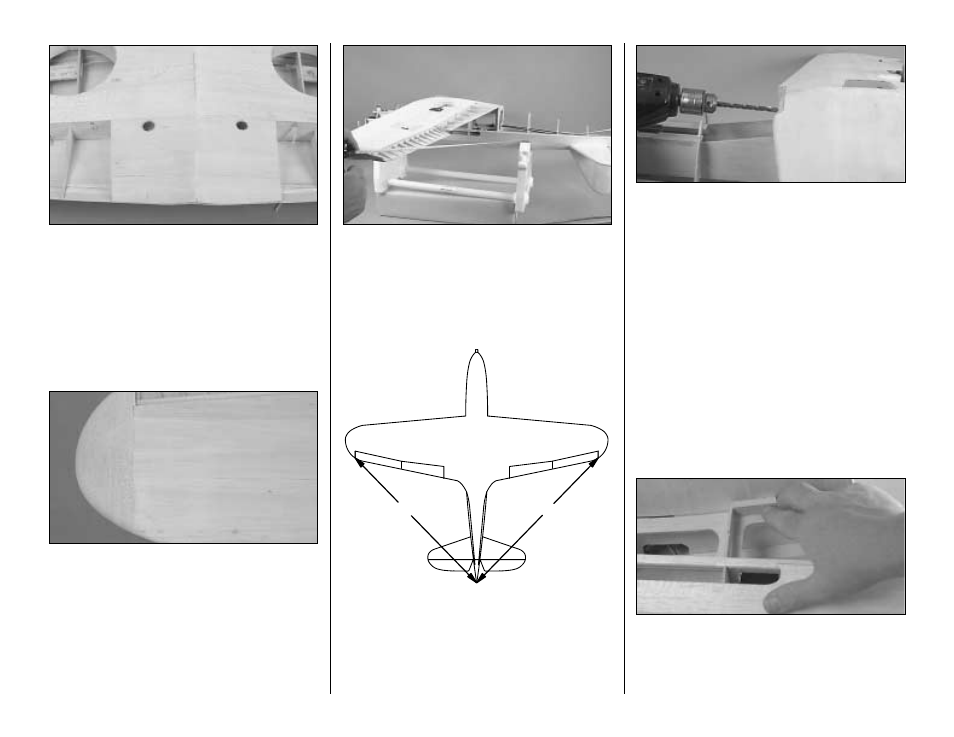

❏ ❏ 15. Using the 1/8" [3.2mm] pilot hole as a guide,

drill through the pilot holes from the top of the wing

through the bottom center section sheeting. This will

give you a proper alignment for the wing bolts. Once

the hole has been drilled, enlarge the diameter of the

hole in the bottom sheeting to allow the head of the

1/4 - 20 nylon wing bolt to pass through the skin

and tighten down onto the wing bolt mounting plate.

Glue a piece of the cardboard wing bolt tube in the

hole between the sheeting.

❏ ❏ 16. Glue the shaped balsa wing tips to the end

of the wing. Shape to match the airfoil of the wing.

Use the plan as a guide for the final shape.

Fit the wing to the fuselage

❏ 1. Test fit the wing onto the wing saddle. Be sure

that the center of the LE is at the center of F3A.

❏ 2. Wing alignment is important to good flight

characteristics so take your time to do it correctly.

With the wing in the saddle, visually check the

alignment of the wing in relation to the horizontal

stab. If needed, sand a small amount of the wing

saddle until the wing is parallel to the horizontal stab.

❏ 3. Measure the distance from the right wing tip to

the center of the fuselage at the tail. Do the same for

the left side of the fuselage. Make adjustments to the

wing position until the distance from the fuselage to

each wing tip is the same. When you are satisfied,

mark the exact wing location on the fuselage.

❏ 4. From the front of the fuselage, drill two 1/4"

holes through the existing holes in F3 and F3A and

into the ply LE dowel brace of the wing. Make sure

that you drill the hole through the ply LE dowel brace

and the aft dowel brace. A long drill bit will be helpful

in doing this step, but if you have only a standard bit,

drill through the LE dowel brace, then remove the

wing and drill the hole through the aft dowel brace.

With the wing off of the fuselage the standard bit will

reach all the way through.

❏ 5. Glue each of the 1/4" x 3" [6.4x 76mm] wood

dowels in place in the holes you drilled. The dowels

should extend out of the dowel brace 3/8" [9.5mm] .

Round the end slightly to help the dowel easily slide

into the fuselage. A small amount of epoxy spread on

the dowels should be more than adequate to retain

the dowels.

❏ 6. When the glue has cured on the dowels, place

the wing in position in the saddle. Place the 1/4"x

3/4" x 2" [6.4 x 19 x 51mm] wing bolt plates in

position under the holes in the wing. Mark these

locations on the side of the saddles.

A

A

35