Top Flite TOPA0145 User Manual

Page 33

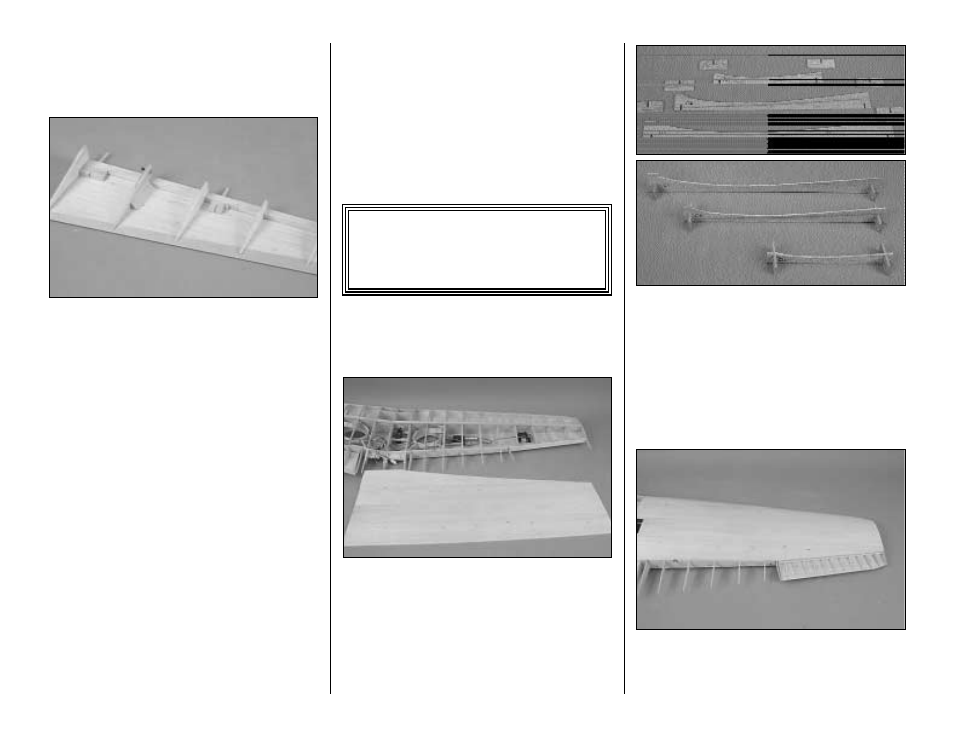

❏ ❏ 16. Locate the 2-56 ball, ball link socket and

2-56 nut. Attach the ball through FR3D and FR3 and

retain it with the nut. After tightening the nut put a small

drop of CA on the threads to prevent it from loosening.

❏ ❏ 17. Cut a small piece of leftover 3/8" [9.5mm]

triangle stock and glue it to FR3 and the flap skin.

❏ ❏ 18. Cut a slot through the trailing edge of the

wing, just large enough for the 2-56 pushrod. See the

photo at step 16.

❏ ❏ 19. Cut one of the 2-56 x 12" [305mm] pushrods

to fit from the bellcrank to the ball link. Make a

Z-bend in the wire and attach it to the bellcrank as

shown on the plan.

❏ 20. Repeat steps 4-19 for the left flap.

Sheeting the flap area when flaps are

not used.

Perform steps 21 and 22 only if there will not be

working flaps.

❏ ❏ 21. Use a new 1/16" x 3" x 30" [1.6 x 76 x

762mm] balsa sheet and a piece of 1/16" [1.6mm]

sheeting that was left over from trimming the wing

sheeting to make the skin for the flap area. Edge

glue the two skins together and cut them to fit onto

the wing using the flap plan as a guide.

❏ ❏ 22. When satisfied with the fit, glue the skin in

place to the wing.

Sheet the top of the Wing

❏ ❏ 1. Glue four of the 1/16" x 3" x 30" [1.6 x 76 x

762mm] balsa sheets together in the same way as

you glued the other sheeting. After the glue has

dried, cut the sheeting to the outline of the wing. Be

sure to save the portion of the sheet that you cut

away at the leading edge. This will be used in step 5.

Note: The sheeting will not cover the entire top of the

wing. The flap area will not be sheeted in

this step.

❏ ❏ 2. Locate balsa parts C1, C6, C11 and six wing

jig braces. Assemble three wing jigs as shown in

the photographs.

❏ ❏ 3. Support the wing with the three wing jigs.

Place C1 at the wing root, C11 at the wingtip and C6

centered in the middle of the wing. Glue the sheeting

in place on the wing using the same method as the

bottom of the wing. Trim the sheeting at the LE, tip

and TE after it has dried.

❏ ❏ 4. Test fit the aileron. Sand the aileron to fit

between the ribs with 1/16" [1.6mm] clearance at

each end of the aileron. Sand the ailerons to match

the airfoil of the wing.

P

P

P

P

-

-

3

3

3

3

9

9

9

9

F

F

F

F

a

a

a

a

c

c

c

c

tt

tt

Approximately 9,560 Airacobras were

produced, about half of which were sent to

Russia under the Lend-Lease program.

33