Top Flite TOPA0145 User Manual

Page 11

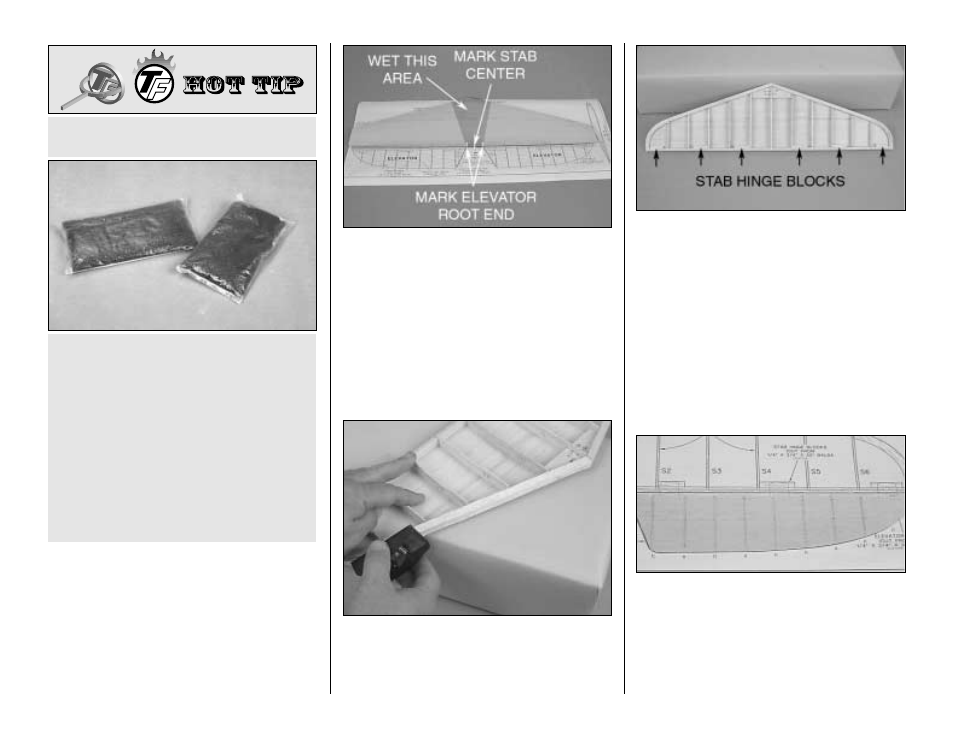

❏ 9. Before you sheet the top of the stab, refer to the

photo at step 10. Use a ballpoint pen and a square

to mark the center of the stab and the root end of

both elevators on the TE of the stab. The marks will

help you align the stab with the fuse and align the

elevators with the stab later on.

❏ 10. Sheet the top of the stab with one of the stab

skins you've already prepared. We recommend

using aliphatic resin to glue the skin to the ribs and

CA to glue the skin to the TE, LE and tips. Wet the

outside of the sheeting in the middle near the leading

edge. This will make the skin flexible enough to glue

to the structure. Apply aliphatic resin to the ribs and

position the top skin on the stab. Place your weights

on top of the stab skin, then use CA to glue the skin

to the LE, TE and tips. Leave the weights in position

until the aliphatic resin dries. Thirty minutes to an

hour is enough time.

❏ 11. Remove the stab from your building board. Turn

the stab over and cut the jig tabs from the bottom of

the ribs, then trim the bottom of the LE even with the

ribs. Trim the stab tips and the bottom of the TE near

the tips the same way you did on the top.

❏ 12. Cut the stab hinge blocks from one of the

1/4" x 3/4" x 30" [6.4 x 19.1 x 762mm] balsa sticks.

Glue the hinge blocks to the TE, ribs, and top

sheeting where shown on the plan. Trim the hinge

blocks even with the TE and ribs.

❏ 13. Sheet the bottom of the stab with the other

stab skin you prepared. Use care not to add any twist

to the stab as it is no longer supported by the jig tabs.

Once again, we suggest using aliphatic resin to glue

the skin to the ribs and medium CA for the rest.

Build the elevators

❏ ❏ 1. Mark the location of the elevator ribs on both

sides of one of the die-cut 3/32" [2.4mm] balsa

elevator core where shown on the plan. This is easy.

Simply lay the die-cut core on the plan and draw a line

from the "tick" marks at the leading and trailing edge

of the elevator core. This will give you the positioning

for the ribs. When you have completed one side

transfer the lines to the other side.

When we glue sheeting to a structure (wing, stab,

fin), we use plastic bags filled with lead shot to

hold the sheeting down. These plastic bags filled

with lead take the shape of the curved surfaces to

apply uniform pressure and do not put marks in

the balsa wood. You can purchase lead shot at

most stores where hunting supplies are sold. We

use #6 lead shot. One 25 lb. [1.134kg] bag costs

approximately fifteen to twenty dollars. You may

use small zip lock food storage bags to hold the

shot. Tape the bags shut to make sure they don't

open. Each bag should hold between 2-3 lbs.

[907-1361g.] of lead. Ten to fifteen 2-3 lbs. [907-

1361g.] bags should be enough for most projects.

WEIGHT BAGS

11