Top Flite TOPA0145 User Manual

Page 21

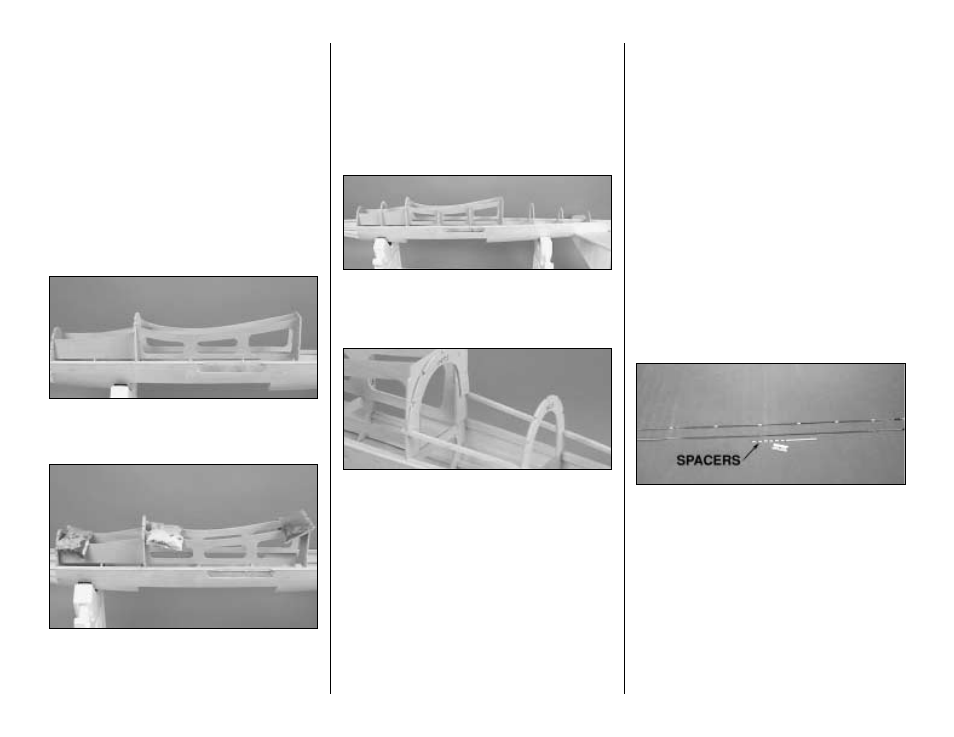

❏ 6. Test fit formers F1A, F3A and F6A to the wing

saddle. The formers and saddle have been notched

to allow the structure to interlock together. When you

assemble this structure, the longer wing saddle

should be on the left side of the assembly.

Remember, you are building this upside down. Make

sure that you have the longer wing saddle on what

will be the left side of the fuselage.

❏ 7. Both formers must be square to the saddles.

When you are satisfied with the fit, glue F3A and F6A

to the saddles with CA.

❏ 8. Glue F1A to the saddle using 30-minute epoxy.

Set the saddle assembly aside to dry.

❏ 9. When the epoxy in the saddle assembly has

cured, test fit the saddle assembly to the fuselage.

❏ 10. When you are satisfied with the fit, glue it

permanently in place onto the fuselage. This should

be done with 5-minute epoxy and some weights to

hold it in place. Allow the epoxy to cure.

❏ 11. Locate the 1/8" x 2-3/4" x 2-3/4"[3.2 x 70 x

70mm] firewall backplate. Glue it to the back of F1

and F1A with 5-minute epoxy. Locate it as shown on

the plan.

❏ 12. Glue two F4A formers and two F5A formers to

each side of the wing saddle as shown on the plan.

Glue former F2A in place as shown on the plan.

❏ 13. Glue formers F7A, F8A, F9A and F10A into

position as shown on the plan. Be sure that they are

straight when you glue them in place. Do not glue

F6AD in position yet.

❏ 14. Temporarily place two balsa side stringers in

position as shown in the photograph. This will give

you the position for gluing F6AD in place. When

satisfied with the fit, glue F6AD to F6A, and remove

the stringers.

Install the Pushrods

❏ 15. Before we close the rest of the fuselage, this

would be a good time to position the pushrods and

servo mounting rails. Locate a 1/4" x 3/8" x 36"

[6.4 x 9.5 x 914mm] basswood stick and cut four

pieces as shown on the plan to fit the fuselage.

These become the servo mounting rails.

❏ 16. Glue the servo mounting rails into position as

shown on the plan (See photo at Step 21.)

❏ 17. Cut a plastic pushrod outer tube to length for

the elevator and put it in place. This tube should go

through the hole that you previously drilled in F9.

Roughen the tube with sandpaper in the areas where

the tubes will be glued.

❏ 18.Mark the rudder pushrod exit on the left side of

the fuse where shown on the fuselage plan. Drill a

3/16" [4.8mm] hole on the mark. Angle the drill

approximately 25 degrees when drilling on the mark.

This will allow the pushrod to exit the fuse at the

correct angle

❏ 19. Cut the plastic pushrod outer tube to length for

the rudder. Roughen the tube with 150 grit

sandpaper where it will be glued to the wood. Glue

the tube in position through the hole you just drilled

in the side of the fuselage.

❏ 20. Cut the .074 wire pushrods to length for each

of the control surfaces. Clean residual oil from the

pushrod wire with a cloth dampened with alcohol or

other solvent. Cut six 3/8” spacers from the white

inner pushrod tube, then slide them, evenly spaced,

onto the wire. Make sure you position the bushings

at the ends of the wire so they will not protrude from

the guide tube, or the controls could become

jammed during flight. If the spacers slide easily onto

the wire, secure them with a drop of thin CA (make

sure the CA sets before you slide the pushrod into

the guide tube!). If the spacers are difficult to slide

on, cut them to a shorter length so they will be a little

easier to slide onto the wire.

21