Build the wing – Top Flite TOPA0145 User Manual

Page 25

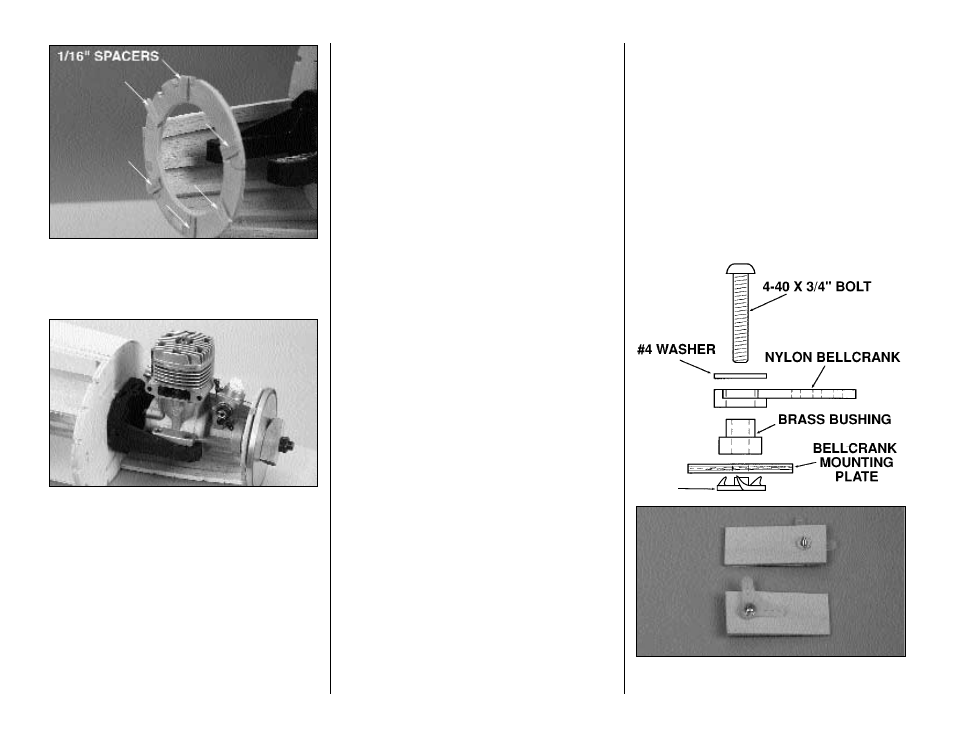

❏ 45. Glue the other half of the nose ring (NR) in

position on the front of the fuselage. Temporarily glue

a few 1/16" [1.6mm] spacers to the nose ring to act

as spacers for the spinner.

❏ 46. Position the engine in place on the engine

mount. With the spinner backplate centered on the

nose ring, tack glue the spinner backplate to the

1/16" [1.6mm] spacers. Lock the spinner backplate in

place with the prop nut. This now shows the exact

position for mounting the engine.

❏ 47. Mark the location of the mounting holes on

the mount. Remove the engine but leave the spinner

backplate glued to the nose ring spacers. Drill a #29

hole ( a 1/8" [3.2mm] bit will be close if you don't have

a set of number bits) and tap the mount with a 8-32 tap.

Hint: The Great Planes Dead Center

™

Tool works

great for this!

❏ 48. Install the engine onto the engine mount and

put the prop nut back on the engine to hold the

spinner backplate tight to the nose ring spacers.

❏ 49. Locate the piece of 3/32" x 2 3/4" [2.4 x 70mm]

balsa sheet that was left over from sheeting the

fuselage on page 16, step 20. Glue it in position from

F2 to the nose ring.

❏ 50. Leave the engine and spinner backplate

mounted in place throughout the entire sheeting of

the fuselage. This will assure you that the nose ring

and spinner backplate will be properly aligned when

the sheeting is glued in place. Some of the

photographs shown in the manual do not show the

engine and spinner backplate mounted. We removed

them for clarity in the instructions, but be sure to

leave the engine and spinner in place as you

continue building.

Hint: When you complete the entire fuselage

construction and sheeting, wet the fuselage sheeting

from F2 forward to the nose ring and let it dry

overnight. After the wood has dried you can break

the spinner backplate away from the nose ring and

the temporary shims.

❏ 51. At this point you must install the pushrod for the

elevator. After we get the fuselage closed you will no

longer have access to the clevis. Make sure when

installing the clevis that you have a piece of tubing

over it to keep it locked in position. You may also

install the rudder and throttle connections at this time.

Set the fuselage aside and get started on the wing.

Don't be concerned that we still have some work

remaining on the fuselage, it will be helpful to leave

it open until the wing is all mounted.

BUILD THE WING

NOTE: The wing panels are built "UPSIDE-DOWN"

on the plan. Since it is the standard procedure to

show the Top View of the wing and the wing

panels are built upside-down, the LEFT wing

panel is built over the RIGHT Wing Top View and

vice-versa. This does not present any problems -

just be sure to build a left and a right wing.

❏ 1. Locate the four 1/4" x 3/8" x 36" [6.4 x 9.5 x

914mm] basswood Wing Spars, then cut them so they

are 1/2" [12.7mm] longer than shown on the plan. Save

the cut-off ends for the flap servo hatch mounts.

❏ 2. Perform this step only if you are going to be

installing flaps. Drill 1/8" [3.2mm] holes through the

4-40

BLIND

NUT

25