Top Flite TOPA0145 User Manual

Page 29

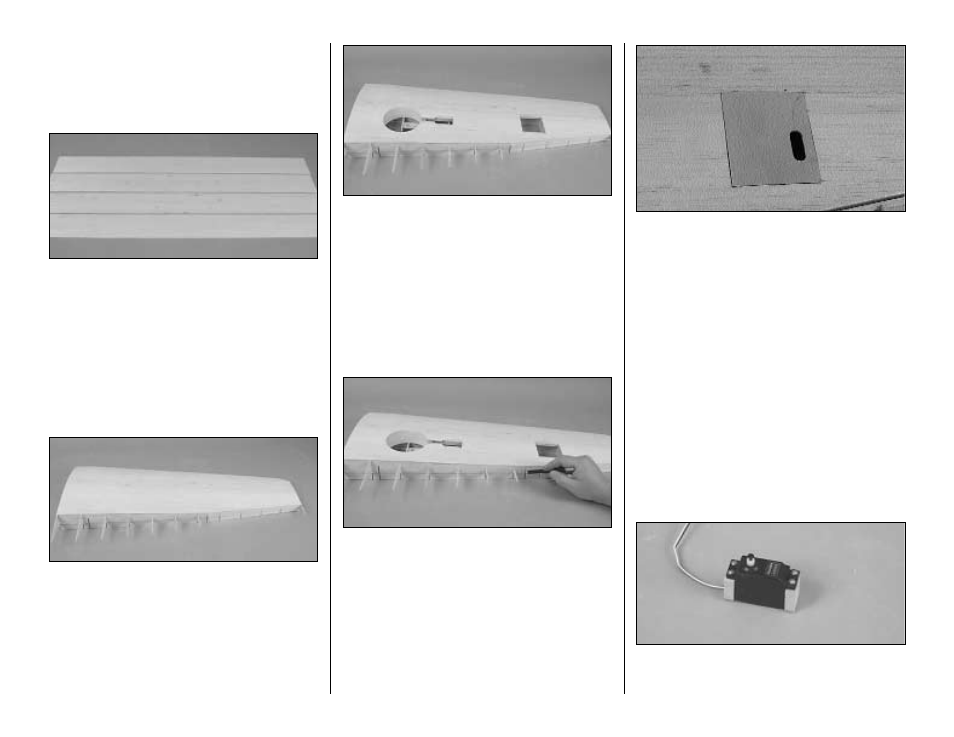

Sheet The Bottom Of The Wing

❏ ❏ 1. Remove the T-pins. Use a sanding bar to sand

the LE, TE spars and ribs so they are smooth and

even. Be careful not to change the shape of the ribs.

❏ ❏ 2. Glue four sheets of 1/16" x 3" x 30" [1.6 x 76

x 762mm] balsa together in the same manner as you

did for the horizontal stabilizer. This will create the

bottom wing skin.

❏ ❏ 3. Cut the skin to the shape of the wing, but cut

it approximately 1/4" [6.4mm] larger than the wing.

This will provide a bit of excess when positioning the

skin. Save the excess that was cut away for later use

in the sheeting process.

❏ ❏ 4. Glue the skin to the wing ribs and spar. Use

an aliphatic glue for this. Tape the leading and trailing

edges of the sheet to the leading and trailing edge of

the wing. Hold the skin in place on the ribs with a few

weighted bags.

Note: DO NOT GLUE the skin to the area around the

aileron hatch cover. This will be cut away in the next

step. Gluing the skin to the spar around the hatch will

make it difficult to cleanly remove the hatch.

❏ ❏ 5. After the glue has dried, cut away the openings

for the landing gear and the aileron servo hatch. Start

by cutting the hatch opening under size and carefully

enlarge it using a fresh #11 blade and a straightedge

until the die-cut 1/16" [1.6mm] ply hatch cover fits.

Hint: As you zero-in on the final shape of the hatch

opening, use the hatch cover itself as a template to

finalize the exact shape and size of the opening.

❏ ❏ 6. Use thin CA to adhere the sheeting at the

aileron hatch opening and the wheel well.

❏ ❏ 7. Cut the trailing edge support on the

embossed line.

Installing the Aileron Servos

This is a good time to get the aileron servos installed.

Doing it now will make it easy to run the wires and

get the hatches to fit.

❏ ❏ 1. Locate the die-cut 1/16" [1.6mm] aileron

servo hatch and fit it to the opening in the wing.

❏ ❏ 2. Use six of the #2 X 3/8" [9.5mm] flat head

sheet metal screws to mount the hatch to the servo

rails. Place the hatch cover on the servo hatch rails

making sure it is in the correct orientation as shown

on the plan. Drill 1/16" [1.6mm] holes through the

punch marks in the hatch cover into the rails.

Enlarge the holes in the hatch cover only with a 3/32"

[2.4mm] drill bit. Countersink the holes for the #2 x 3/8"

[9.5mm] flat head screws with a countersink or Dremel

#178 bit. Test fit the hatch cover to the rails with the

screws. If necessary, sand the edges of the hatch cover

so they align with the edges of the hatch opening.

Note: If you find it difficult to countersink the holes in

the hatch cover for the flat head screws, you could

use regular #2 x 3/8" [9.5mm] screws (not supplied)

and not countersink the holes.

❏ ❏ 3. Locate two of the 5/16" x 3/4" x 7/8" [7.9 x

19.1 x 22.2mm] basswood aileron servo mounting

blocks and mount the servo to the blocks.

29