0 belt, 0 blower bearings and belts, 0 drive components – Reznor MAPSII Series REDA Users Manual User Manual

Page 7

Form RZ-NA O-MAPS II, P/N 209179 R7, Page 7

������

�����

������

������

�����������

�����������

�������������

����������

��������

������

������

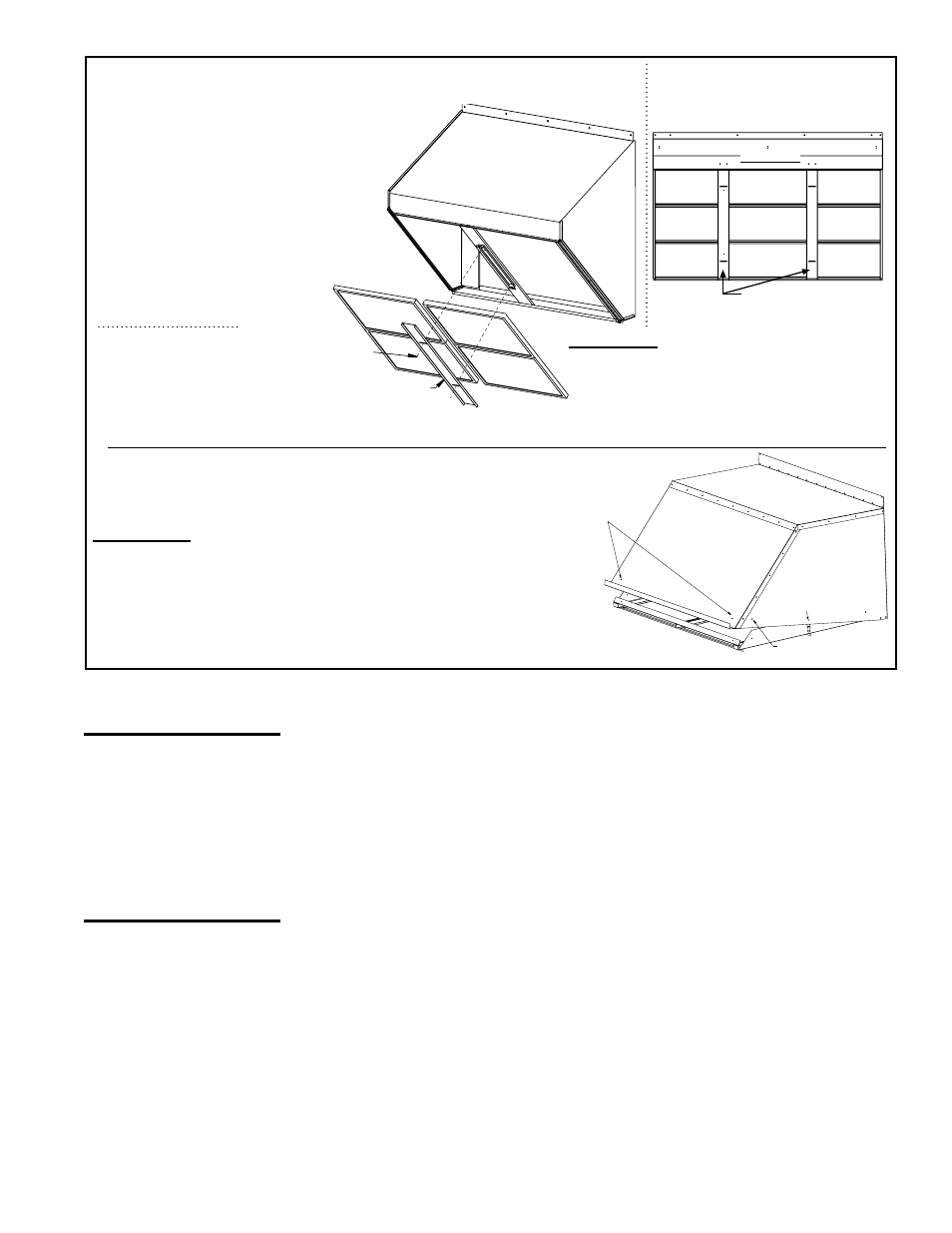

FIGURE 2A -

Removing Filters

from Outside

Air Hood

1" Permanent Aluminum

Filters for Outside Air

Hood are listed by

Cabinet Size A, B, or C

(see page 6)

*A - (4) 16 x 20,

P/N 101607

*B - (4) 16 x 25,

P/N 101609

C - (3) 16 x 25, P/N

101609; (6) 16 x 20,

P/N 101607

Cabinet Sizes A and B with Option

AS16 Outside Air Hood

(Does not apply if

system includes

Option PE

power

exhaust;

see below.)

��������������������

����������������

����������

������

�������

������

�������

������

�������

������

�������

������

�������

������

�������

������

�������

������

�������

������

�������

����������

All Cabinet Size C with

Outside Air Hood Option

AS16 or AS19

Instructions: Remove filters by loosening the

wing screws and sliding the filter clamp(s).

Clean with soap and water, allow to dry,

and replace. If it is more convenient to keep

an extra clean set of filters, quantities, filter

sizes, and part numbers are listed.

* Apply only to Cabinet

Size A and B with outside air hood Option AS16.

�������������

�������������

������������

����������

�������������������

������

���

�������

FIGURE 2B - Removing Filters from Option AS19

Outside Air Hood Installed on a Cabinet Size A or B

with power exhaust Option PE1 or PE2

Instructions: 1)

Remove the four screws as illustrated.

Lower the tray.;

2) Pull out filters. Clean with soap and

water. Allow to dry.;

3) Slide clean dry filters into tray.;

4) Re-position tray and replace screws.

1" Permanent Aluminum Filters

**A - (4) 18 x 20,

P/N 194903

**B - (4) 20 x 25,

P/N 101610

** Apply only to Cabinet Size

A and B with outside air hood

Option AS19.

4.0 Drive

Components

Bearings - Bearings with a grease fitting should be lubricated twice a year with

a high temperature, moisture-resistant grease. (Type NLGI-1 or -2 standard

grease is recommended.) Be sure to clean the grease fitting before adding

grease. Add grease with a handgun until a slight bead of grease forms at the

seal. Be careful not to unseat the seal by over lubricating. NOTE: If unusual

environmental conditions exist (temperatures below 32°F or above 200°F;

moisture; or contaminants), more frequent lubrication is required.

CAUTION: If the

blower is unused

for more than three

months, bearings

with a grease fitting

should be purged

with new grease

prior to start-up.

Setscrews - Check all of the setscrews (bearing/blower hubs and pulleys).

Torque pulley setscrews a minimum of 110 in-lb to 130 in-lb maximum.

A bearing hub setscrew for a 1-3/8" to 1-3/4" shaft requires a 5/16" socket and

a tightening torque of 165 in-lbs.

Belts - Check belt for proper tension and wear. Adjust belt tension as needed.

Replace worn belts.

Blower systems are equipped with either Power Twist Plus

®

linked blower belt

or a solid belt. The linked belts are designed in sections allowing for easy sizing

and adjustment. The belt is sized at the factory for the proper tension. If the belt

needs adjustment, the recommended method of shortening the belt length is to

count the number of links and remove one link for every 24. (A link is made up

of two joining sections of belt. For easier removal of links, turn the belt inside

out. But be sure to turn it back before installing.)

If equipped with a solid belt, adjust the belt tension by turning the adjusting

screw on the motor base until the belt can be depressed 3/4" (19mm). After

correct tension is achieved, re-tighten the locknut on the adjustment screw.