0 compressor maintenance and replacement (cont'd) – Reznor MAPSII Series REDA Users Manual User Manual

Page 14

Form O-MAPS II, P/N 209179 R7, Page 14

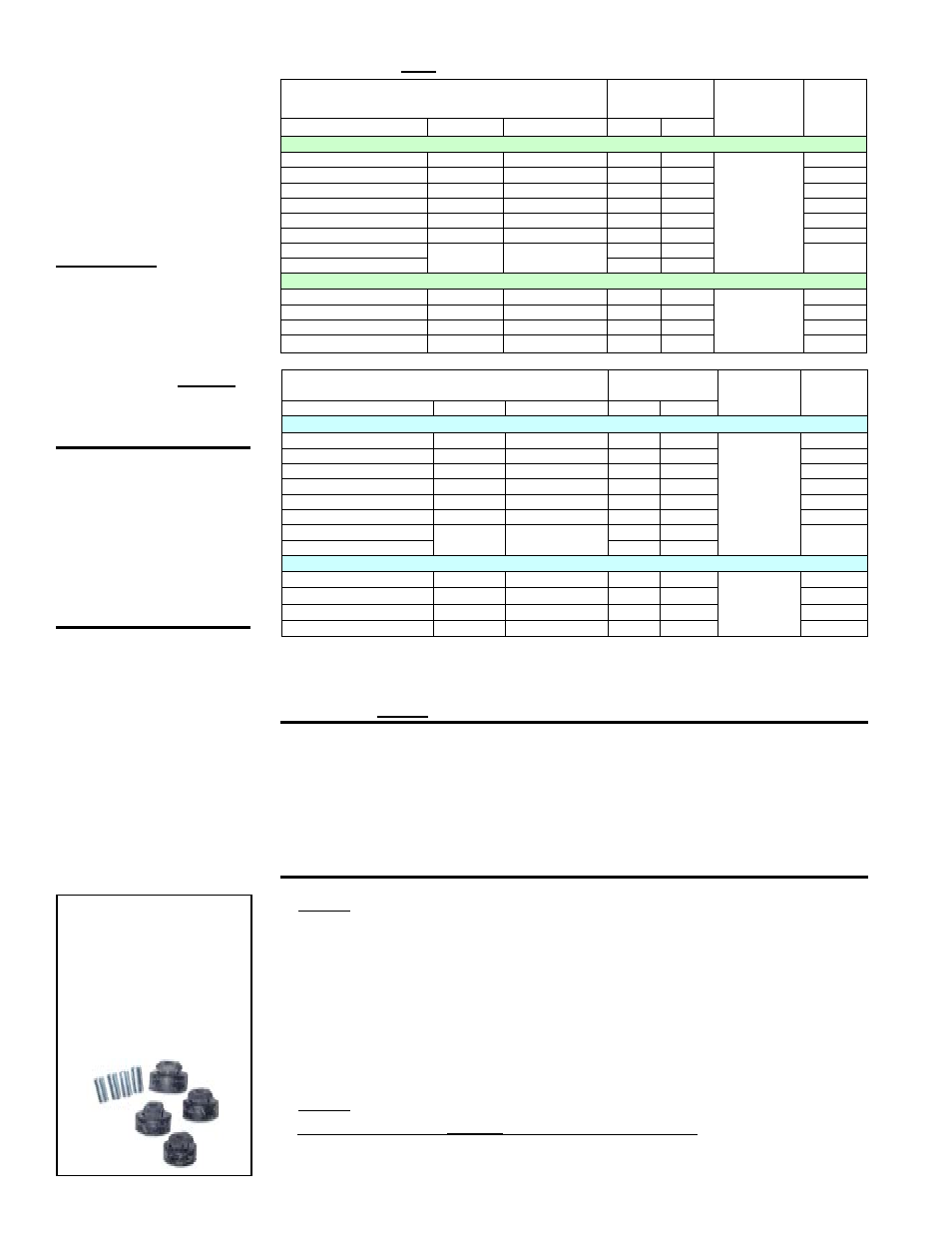

Oil Charge in R22 Compressors used on MAPS II Units

CAUTION: POE oil

used with R407C

refrigerant is irri-

tating to skin and

eyes. Gloves and

safety glasses are

essential.

Oil Charge in R407C

Compressors used

on MAPS II Units

Compressor

Maintenance

Checklist,

Steps 1-13 cont'd)

FIGURE 8 - Install

the new Mounting

Grommets

(isolators)

shipped with the

Replacement

Compressor

Use a field-provided acid test kit (be sure the kit is designed for the

appropriate refrigerant) to check the oil for acid. If acid is found, begin-

ning in

Step 4 follow the procedures indicated for burnout cleanup.

CAUTIONS: The compressor may contain harmful acids. Be

sure to handle with extreme care using proper protective

equipment. After testing for acid and checking the oil charge

level, return the oil to the compressor being replaced. Braze

the discharge and suction copper closed. Use an approved

disposal method to dispose of the compressor and the oil.

Compressor (by P/N & Location; refer to FIGURE 7) Oil Charge (each

compressor)

Oil Type

Nominal

Circuit

Capacity

P/N's

Location Mfr Designation (cc)

(oz)

Oil Charge - MAIN Cooling Circuit Compressors (A, B, C, D) with R22 Refrigerant

205622 / 205609

A or B

ZR22

1124

38

Conventional

White Oil

(Sontex 200LT is

recommended.)

2 tons

205610 / 205623 / 205624 A, B, C, or D

ZR36

1242

42

3 tons

205611 / 205612 / 205625

A, B, or C

ZR54

1952

66

4.5 tons

205626 / 205613 / 205627

A, B, or C

ZR72

1774

60

6.2 tons

207351 / 207352 / 207353

A, B, or C

ZR125

3253

110

10 tons

207348 / 207349 / 207350

C

ZR144

3253

110

12 tons

207356 / 207355

A or B

ZR144 (twin)

1774

60

12 tons

207354

3253

110

Oil Charge - Re-heat Heat Pump Circuit Compressor (Dh) with R22 Refrigerant

205622 / 205609

Dh

ZR22

1000

34

Conventional

White Oil

(Sontex 200LT is

recommended.)

2 tons

205610 / 205623

Dh

ZR36

1064

36

3 tons

205611 / 205612

Dh

ZR54

1064

36

4.5 tons

205626 / 205613

Dh

ZR72

1064

36

6.2 tons

Compressor (by P/N & Location; refer to FIGURE 7.) Oil Charge (each

compressor)

Oil Type

Nominal

Circuit

Capacity

P/N's

Location Mfr Designation (cc)

(oz)

Oil Charge - MAIN Cooling Circuit Compressors (A, B, C, D) with R407C Refrigerant

217244 / 220715

A or B

ZR22

1124

38

Polyol Ester Oil

(POE) - ULTRA

32CC is

recommended.

2 tons

220375 / 216936 / 220716 A, B, C, or D

ZR36

1242

42

3 tons

217246 / 216937

A, B, or C

ZR54

1952

66

4.5 tons

217245 / 216938 / 220717

A, B, or C

ZR72

1774

60

6.2 tons

220712 / 216939 / 220718

A, B, or C

ZR125

3253

110

10 tons

220713 / 216940 / 220719

C

ZR144

3253

110

12 tons

2169410 / 220720

A or B

ZR144 (twin)

1774

60

12 tons

220714

3253

110

Oil Charge - Re-heat Heat Pump Circuit Compressor (Dh) with R407C Refrigerant

217244 / 220715

Dh

ZR22

1000

34

Polyol Ester Oil

(POE) - ULTRA

32CC is

recommended.

2 tons

220375 / 216936 / 220716

Dh

ZR36

1064

36

3 tons

217246 / 216937

Dh

ZR54

1064

36

4.5 tons

217245 / 216938 / 220717

Dh

ZR72

1064

36

6.2 tons

Step 3. Mount the Replacement Compressor

Do not remove the dust cover or rubber shipping plugs until all other sys-

tem connections are complete (i.e. new liquid line filter drier(s) installed

and all tubing changes made - see Steps 4 and 5). The amount of time the

compressor is open to the atmosphere should be kept to a minimum.

Use the new mounting grommets and sleeves that are shipped with the

compressor to mount it. The sleeves will prevent over compression of

the grommets. Re-use the mounting bolts from the compressor that was

removed. The mounting bolts will bottom out when tight.

Step 4. Install New Filter Driers (Select the procedure that applies.)

If the test for acid in

Step 2 did NOT indicate burnout, install a new liquid

line filter drier. The filter drier must be the proper type and size for the cir-

cuit. Install a temporary field-supplied suction line filter drier.

7.0 Compressor

Maintenance

and

Replacement

(cont'd)