Index, Keep all booklets for future reference, 0 troubleshooting (cont'd) – Reznor MAPSII Series REDA Users Manual User Manual

Page 28

Form O-MAPS II, P/N 209179 R7, Page 28

Record installation information on the back

of the installation manual, Form I-MAPS II.

Keep ALL booklets for future reference.

www.RezSpec.com; (800) 695-1901

©2008 Thomas & Betts, All rights reserved.

Trademark Note: Reznor

®

and MAPS

®

are registered in the United States.

9/08 Form O-MAPS II (Version B.3)

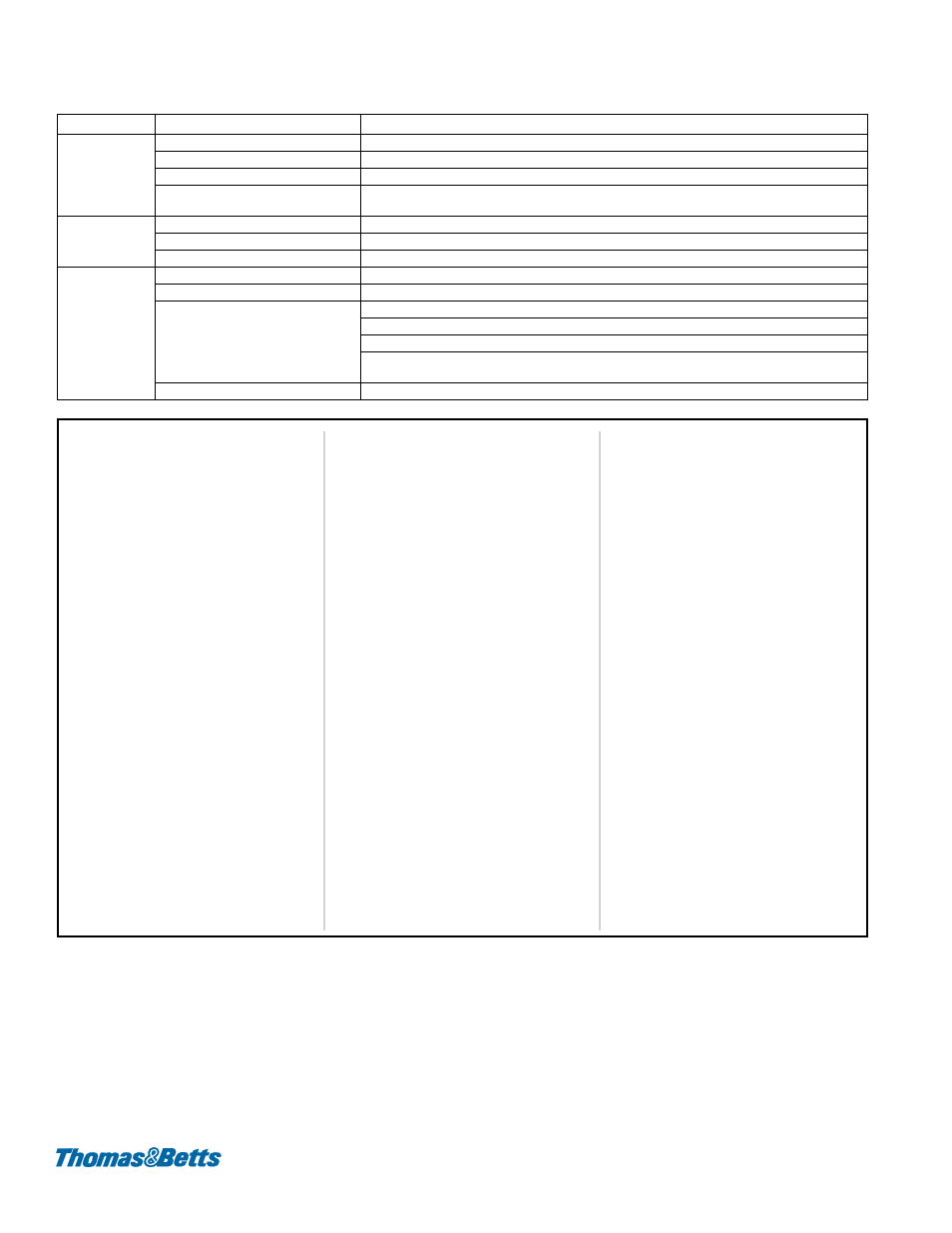

Troubleshooting the Electric Heat Section - Models REDA and RECA

11.0 Troubleshooting (cont'd)

PROBLEM

PROBABLE CAUSE

REMEDY

Unit does not

operate

1. No power to unit

1. Turn on power; check supply fuses or main circuit breaker.

2. Blown fuses

2. Check and replace if necessary.

3. Defective or incorrect wiring.

3. Check wiring and connections. Refer to wiring diagram provided with unit.

4. Defective or burned out control

transformer

4. Check secondary voltage with voltmeter. Replace if necessary.

Fan operates but

element does

not heat

1. Dirty filters

1. Check filters and clean or replace if necessary.

2. Defective air proving switch

2. Check and replace if necessary.

3. Blown element fuses

3. Check and replace element fuses if necessary.

Insufficient heat 1. Burned out element

1. Turn off power and check element resistance with ohmmeter. Replace if open.

2. Blown fuses

2. Check and replace if necessary.

3. Cycling on limit control

3.

a) Check air throughput (temperature rise).

b) Check motor rpm against nameplate rating. Replace motor if speed is too slow.

c) Defective limit control. Check wiring and connections. Check continuity through control and

replace if necessary.

4. Defective or incorrect wiring.

4. Check wiring and connections. Refer to wiring diagram provided with unit.

Index

B

Belt 7

Brazing 15

Burner Maintenance 21

Burner Orifices 22

Burner Removal Instructions 21

C

Charge the System 17

Coil Maintenance 8

Combustion Air Pressure Switch 24

Condenser Coil Connections 8

Cross-Reference by Model/Size and

Curb duct furnace 21

D

DSI Integrated Control Module 22

Duct furnace 21

E

Electric Heat Section Maintenance 25

Evacuate the System 16

Evaporative Coils 8

F

Filters in the Outside Air Hood 6

G

Gas Heat Section Maintenance 20

Gas Valves 24

GENERAL 2

H

Hazard Intensity Levels 3

I

Ignition System 22

Ignitor 23

Inlet Air Filters 6

L

Lights on the DSI Integrated Control

Limit Control 24

Locations of Standard and Optional

M

Maintenance Schedule 3

O

Outside Air Hood 7

R

Re-Heat Pump 10

Refrigerant Temperatures 10

S

Signal Conditioner 24

Superheat 18

System Startup 18

T

Thermal Expansion Valves 20

Troubleshooting - Gas Heat Section

Troubleshooting Gas Heat Section 26

Troubleshooting the Electric Heat Sec-

tion 28

V