0 compressor maintenance and replacement (cont'd) – Reznor MAPSII Series REDA Users Manual User Manual

Page 16

Form O-MAPS II, P/N 209179 R7, Page 16

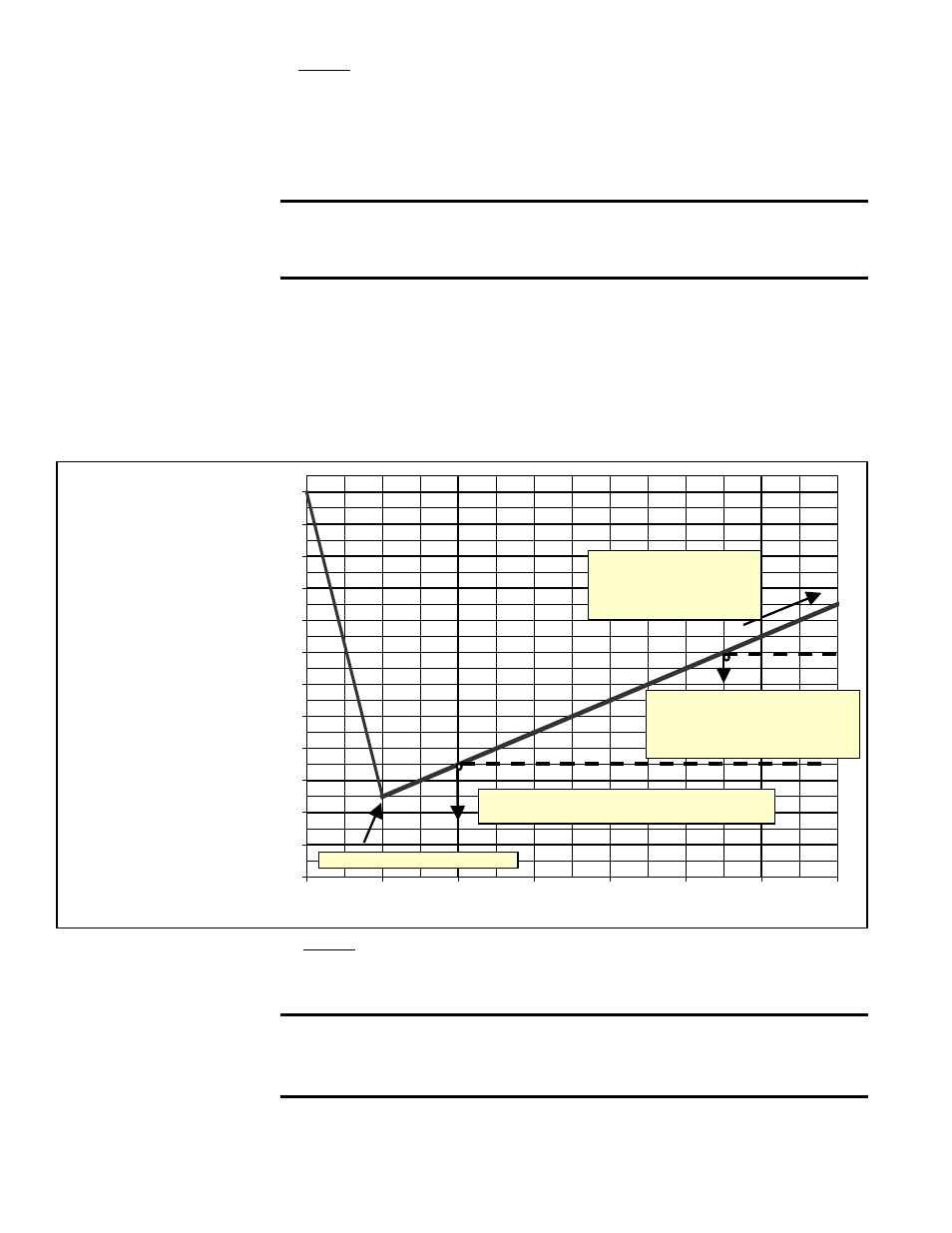

FIGURE 9 -

Pressure Rise

vs Time

IMPORTANT

NOTE:

Always check

gauge hose

connections

for leaks prior

to evacuation.

Step 8. Check the Electrical System

While the system is being evacuated, connect the electrical plug to the

compressor. It is a normal practice to replace all starting components any

time a compressor is changed.

WARNING: Voltage should not be applied to the compressor

when the terminal plug is removed as personal injury could

result.

Compressor

Maintenance

Checklist,

Steps 1-13 (cont'd)

If there is a crankcase heater, connect it. The crankcase heater is ener-

gized continuously and is extremely important to proper compressor oper-

ation and long life.

0

200

400

600

800

1,000

1,200

1,400

1,600

1,800

2,000

2,200

2,400

-20

0

20

40

60

80

100

120

Time (minutes)

Pressure (microns)

Evacuate to 500 microns or lower.

If system holds a vacuum at or below 700 microns,

the system is sufficiently dry and has no leaks.

If system holds a steady vacuum in

this region, there are no leaks. But

the system is not sufficiently dry. Re-

evacuate to remove excess moisture.

If system pressure continues

to rise, the system has leaks.

The leaks must be found and

sealed prior to re-evacuating.

Time varies by moisture level.

Step 7. Evacuate the System

Use a vacuum pump rated for a minimum capacity of 6 cfm. Vacuum must

be pulled on both the discharge (high) and suction (low) sides of the sys-

tem. Evacuate to 500 microns or lower.

Moisture and air are harmful to the system because they increase the con-

densing temperature, raise the discharge gas temperature, cause forma-

tion of acids, and cause oil breakdown.

CAUTION: Do not use the replacement compressor as an

evacuation assist and never apply voltage to a compressor while

it is in a vacuum.

Acids are corrosive to the components in the refrigeration system. This

includes the piping, refrigerant specialties, and the compressor’s mechani-

cal and electrical components. The elevated temperatures can cause cop-

per plating resulting in premature mechanical failure of the compressor.

To establish that the unit is leak-free and moisture-free, a standing vacuum

test is recommended. The maximum allowable rise over a 18-minute

period is 200 microns. If

the rise exceeds this, either there is a leak or

moisture still exists in the system. See the chart in

FIGURE 9.

7.0 Compressor

Maintenance

and

Replacement

(cont'd)