Gas valves, Combustion air pressure switch, Limit control – Reznor MAPSII Series REDA Users Manual User Manual

Page 24

Form O-MAPS II, P/N 209179 R7, Page 24

9.0 Gas Heat

Section

Maintenance

(cont'd)

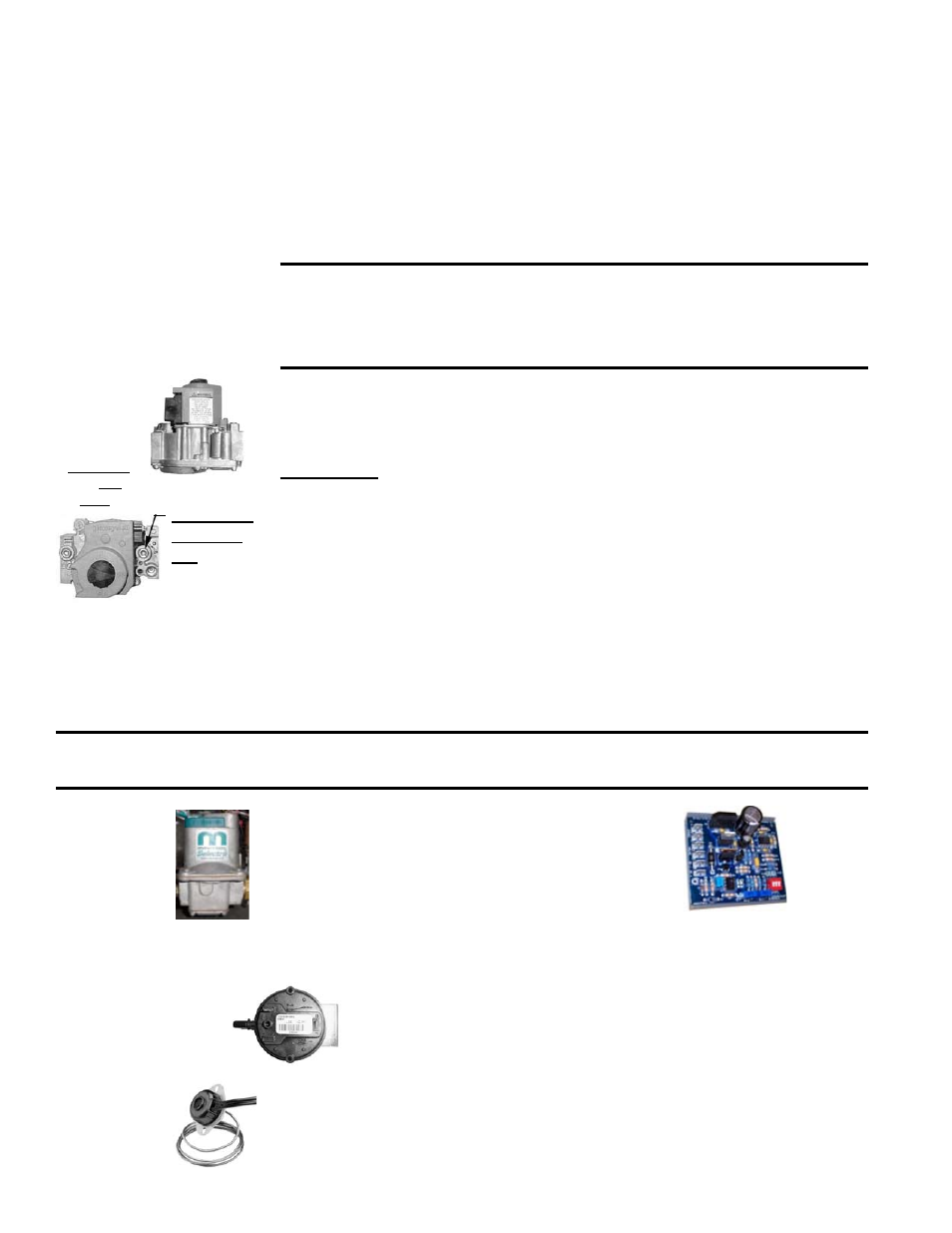

Gas Valves

Carefully remove external dirt accumulation from the valve and check wiring

connections.

The combination gas valves must be checked annually to ensure that each

valve is shutting off gas flow completely.

Instructions:

1) Locate the 1/8" NPT pressure tap on the first combination valve (see illus-

tration on the left).

2) Turn the manual valve OFF to prevent flow to the manifold. Connect a

manometer to the 1/8” outlet pressure tap of the first single-stage valve.

NOTE: A manometer (fluid-filled gauge) with an inches water column scale

is recommended.

Turn the manual valve ON and the heater off.

3) Use your finger to fully block the burner orifice. Continue blocking the ori-

fice for several seconds and observe the manometer. If any pressure is

indicated, the gas valve is leaking. A leaking gas valve must be replaced

before the heater is put back in operation.

4) Repeat the test with each single-stage gas valve.

Single-

Stage

Gas

Valve

(Side View

and Top

View)

WARNING: The operating valve is the prime safety shutoff.

All gas supply lines must be free of dirt or scale before con-

necting to the unit to ensure positive closure. See Hazard

Levels, page 3.

1/8” Outlet

Pressure

Tap

Units with optional 6:1 turndown (Option AG57) include

a modulating/regulating valve in addition to the two

single-stage valves. The modulating/regulating valve

is controlled by a signal conditioner responding to the

system controller to provide the modulated gas flow

for 6:1 turndown. The only field maintenance to the

modulating gas valve is to carefully remove dirt accu-

mulation and to check wiring connections.

Modulating/

Regulating

Valve in

Optional 6:1

Gas Control

Maxitrol Signal

Conditioner used in

Control Option AG57

P/N

131470

Combustion Air

Pressure Switch

See

FIGURE 1A, page 5, Item 17, for location. If it is determined

that the pressure switch needs replacing, use only the factory-autho-

rized replacement part that is designed for the model and size of gas

heater being serviced.

Limit

Control

The limit control is located in the blower compartment with the capillary extend-

ing across the heat exchanger. (

NOTE: For Model JHUP curb duct furnace,

see Form I-MAPS, Paragraph 9.4 for location.)

If it is determined that the limit control needs replacing, use only a factory-

authorized replacement part that is designed for the size of heater.

Install the orifice adapter nuts and the gas orifices being careful not to

damage the venturi tubes and/or the brackets. Re-connect the wires to the

gas valves.

3. Re-attach the venter assembly. (If replacing venter parts, follow instructions

above.) Re-connect the tubing and wires.

4. Close the access panel.

5. Reconnect the gas supply at the union outside of the cabinet. Leak test the

connection with leak detecting solution.

6. Turn on the electric and the gas. Check for proper operation.

Re-Assemble the Heat Section Gas Train, Burner, & Venter (cont'd)

CAUTION: DO NOT bottom out the gas valve regulator adjusting screw. This can result in

unregulated manifold pressure causing excess overfire and heat exchanger failure.